A test device and method for simulating the formation process of in-situ environmental filling body strength

A test method and technology of a test device, which are applied to measurement devices, instruments, scientific instruments, etc., to achieve the effects of low cost, stable monitoring results, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

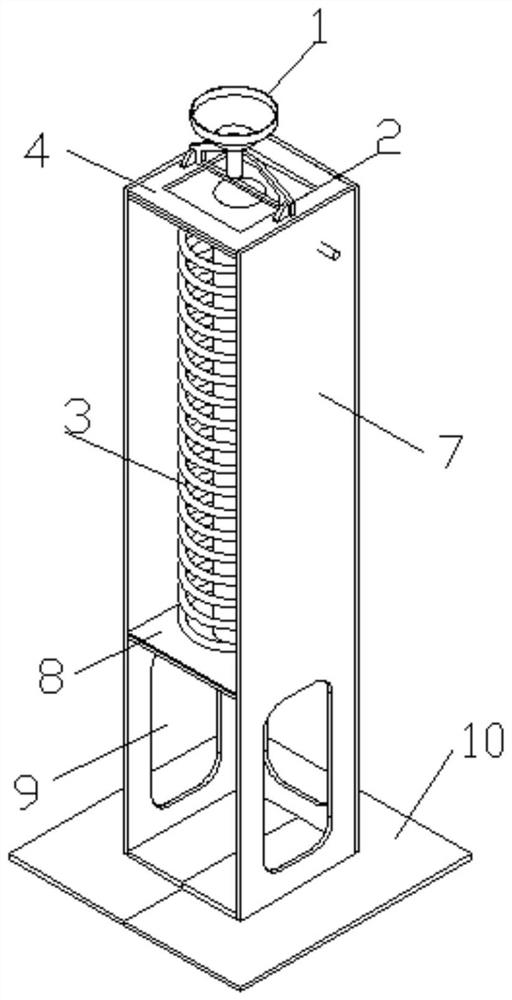

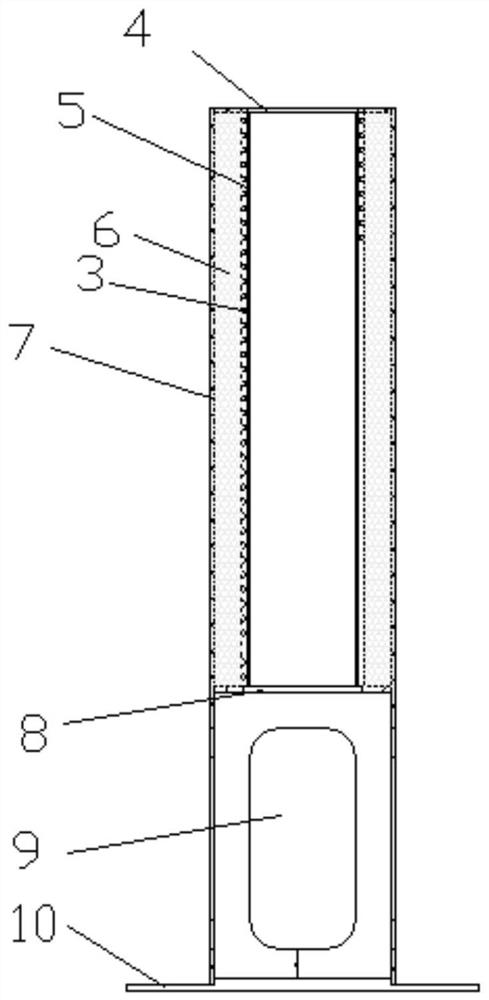

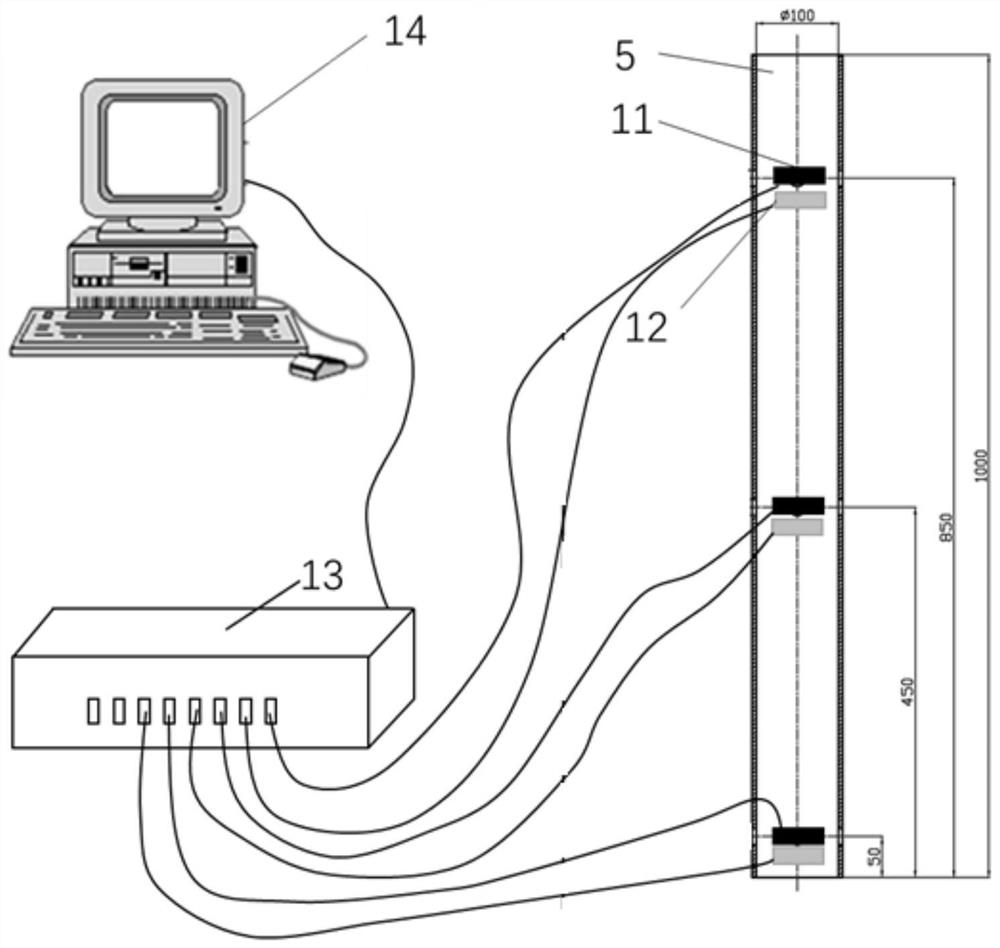

[0035] like Figure 1-3 As shown, a test device for simulating the formation process of the in-situ environmental filling body strength, including a pore piezometer, a matrix suction meter, a humidity sensor, a fiber Bragg grating strain sensor 11, a fiber Bragg grating temperature sensor 12, and a fiber Bragg grating sensor demodulator 13 , a laser displacement meter, a thermostat and a molding structure, the molding structure includes a base 10, a wooden shell 7, a lower filter plate 8, a cylindrical cavity 5, an upper cover 4, a plastic hose 3, polyurethane thermal insulation foam 6, a bracket 2 and the feeding funnel 1, the wooden casing 7 is arranged on the base 10, the lower filter plate 8 is arranged in the wooden casing 7, the cylindrical cavity 5 is placed on the lower filter plate 8, and the upper cover 4 is provided with a round hole , the upper cover 4 is installed on the upper end of the wooden shell 7, the plastic hose 3 is wound outside the cylindrical cavity 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com