24G frequency modulation continuous wave level meter

A frequency-modulated continuous wave and level meter technology, which is applied in the field of level meters, can solve problems such as inconvenient angle adjustment, and achieve the effects of improving production efficiency, saving manpower, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

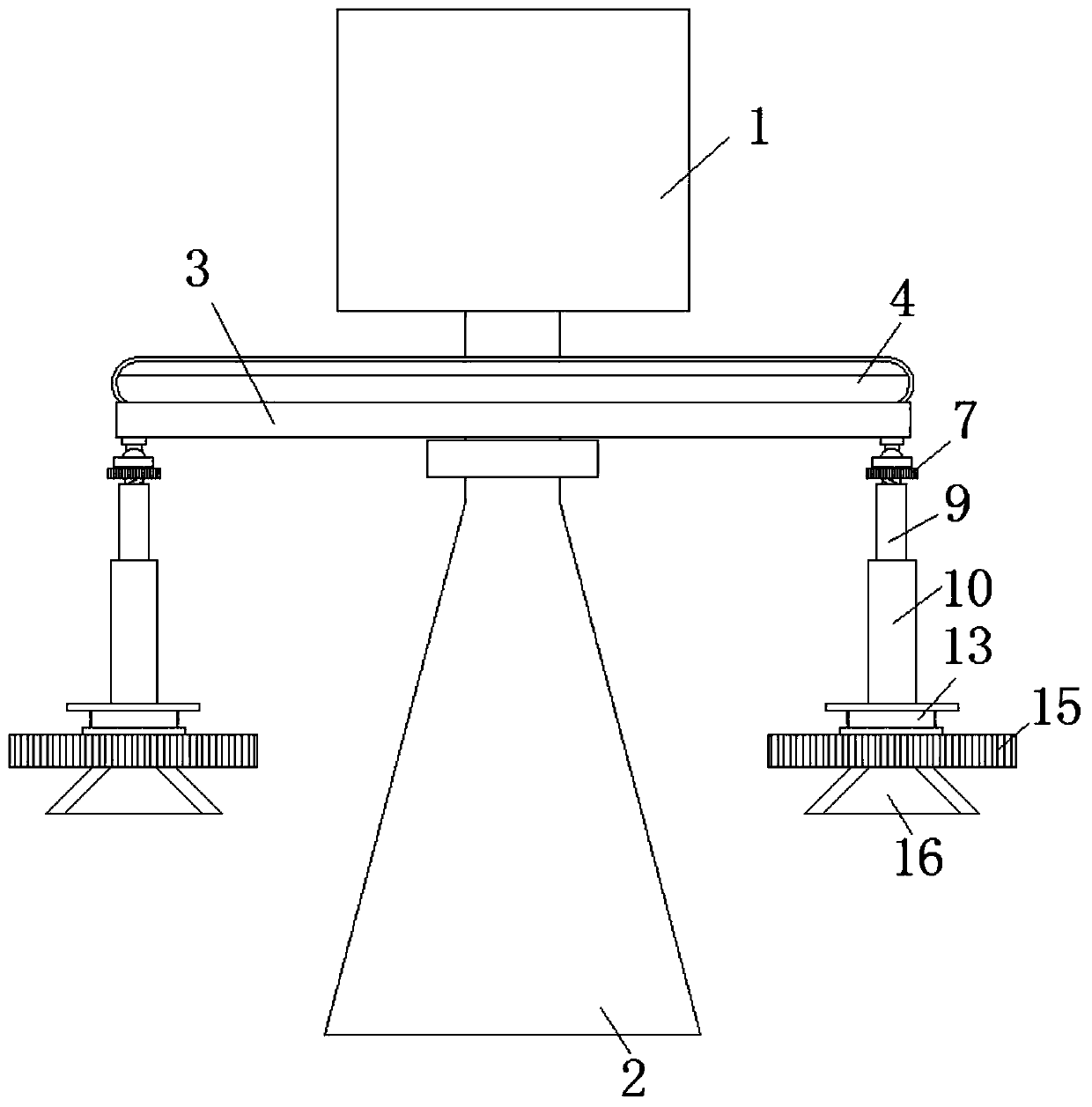

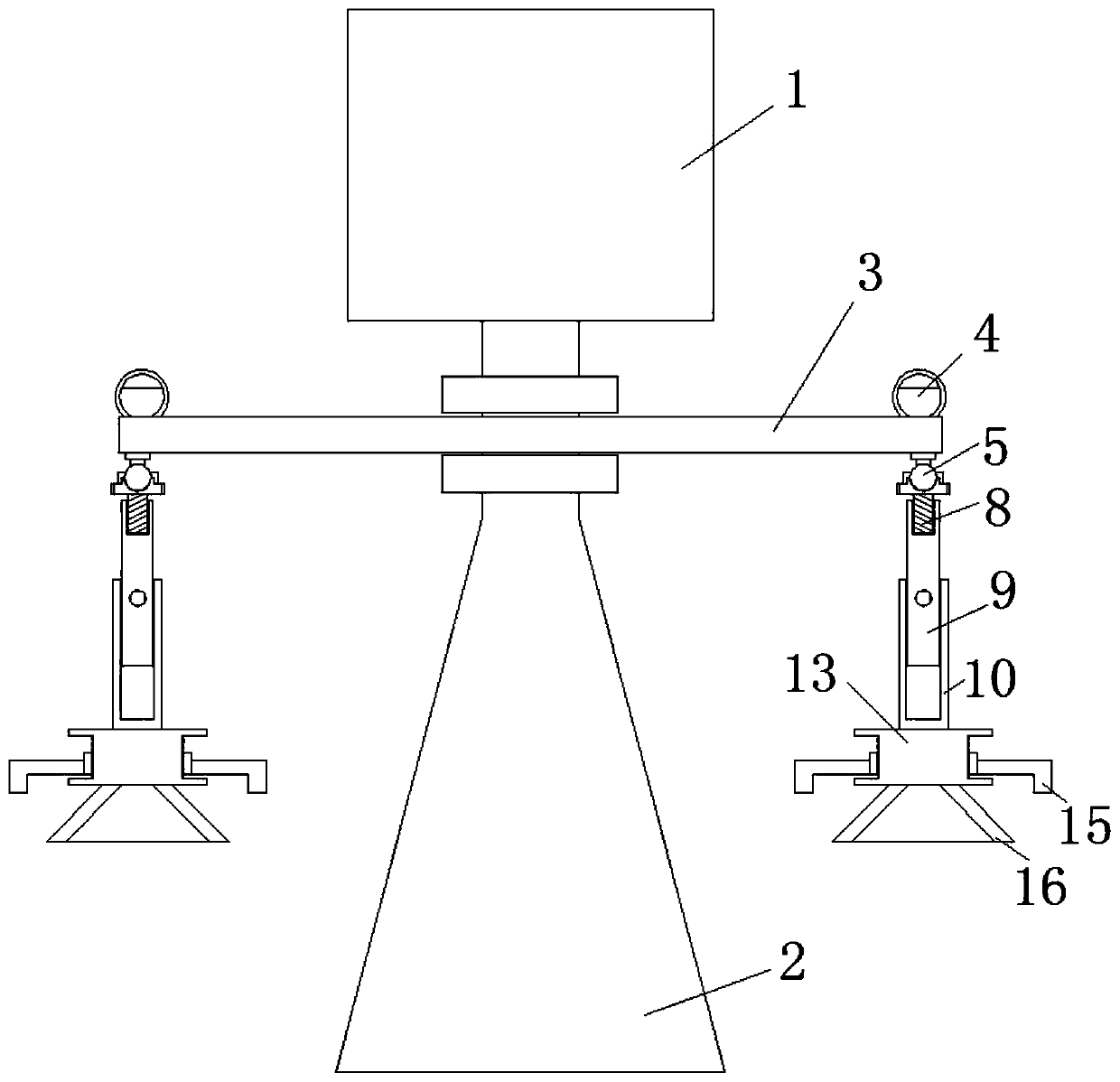

[0024] refer to Figure 1-4 , a 24G frequency modulation continuous wave level meter, including a meter body 1, a detection head 2 and a mounting plate 3, the meter body 1 is installed on the top side of the mounting plate 3, and the bottom end of the detection head 2 extends to the bottom side of the mounting plate 3 , the bottom side of the mounting plate 3 is fixedly welded with a swivel ball 5, and there are three swivel balls 5 that are equidistantly arranged, and the outer top of the swivel ball 5 is provided with an upper cover ring 6, and the bottom side of the swivel ball 5 is connected with a bottom sleeve 7. The top side of the bottom cover 7 is provided with grooves, the outer wall of the bottom cover 7 and the bottom inner wall of the upper cover ring 6 are provided with thread grooves, and the upper cover ring 6 is threaded on the top of the bottom cover 7, and the bottom cover 7 A threaded rod 8 is fixedly welded on the bottom side of the threaded rod 8, and the...

Embodiment 2

[0027] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the threaded post 13 is an I-shaped structure, and the threaded barrel 14 is threadedly disposed on the outside of the threaded post 13 .

[0028] In this embodiment, the rotation of the threaded cylinder 14 on the outside of the threaded column 13 adjusts the distance from the bottom end of the auxiliary fixing ring 15 to the outer wall of the silo.

Embodiment 3

[0030] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a horizontal observation tube 4 is connected to the top side of the mounting plate 3, and the horizontal observation tube 4 is an annular sealed transparent tube.

[0031] In this embodiment, when the outer wall of the silo is horizontal, it is convenient for people to level the mounting plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com