Restoration method for lining cavities of highway tunnels with poorer surrounding rock

A technology for highway tunnels and repair methods, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of insufficient thickness of the secondary lining and structural safety, and achieve the effects of beautiful appearance, rapid prototyping, and structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

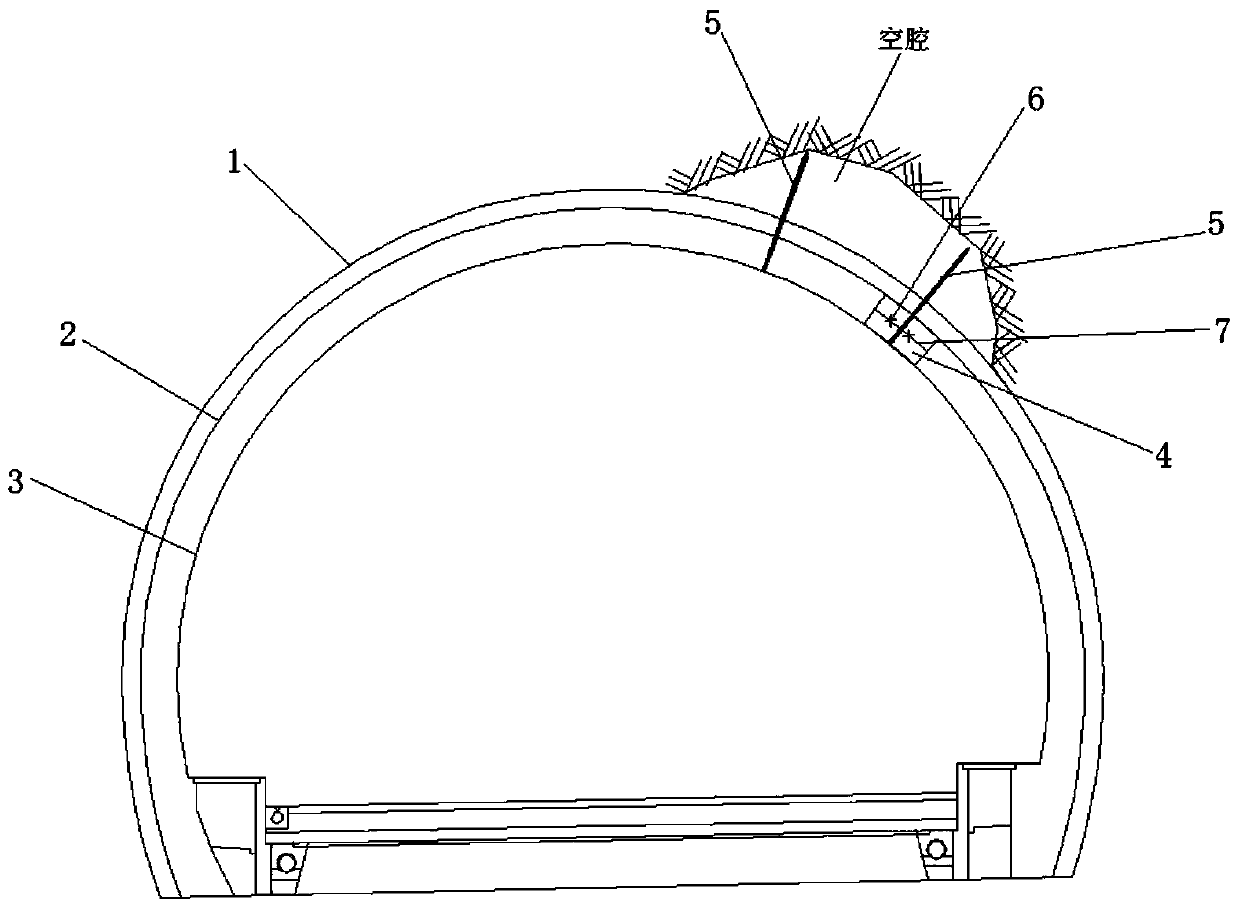

[0031] A method for repairing the lining cavity of road tunnels with poor surrounding rock, such as figure 1 , figure 2 Shown: Include the following steps:

[0032] a. Use the geological radar with the corresponding frequency antenna to find out the cavity or void situation. The model of the geological radar is TSP203 or TSP203A; detect the cavity or undense range and position of the secondary lining 3 and the initial support 1 of the tunnel, cooperate The geological hammer lightly taps the echo, and marks the outline line of the cavity or undense part in detail on the surface of the secondary lining 3;

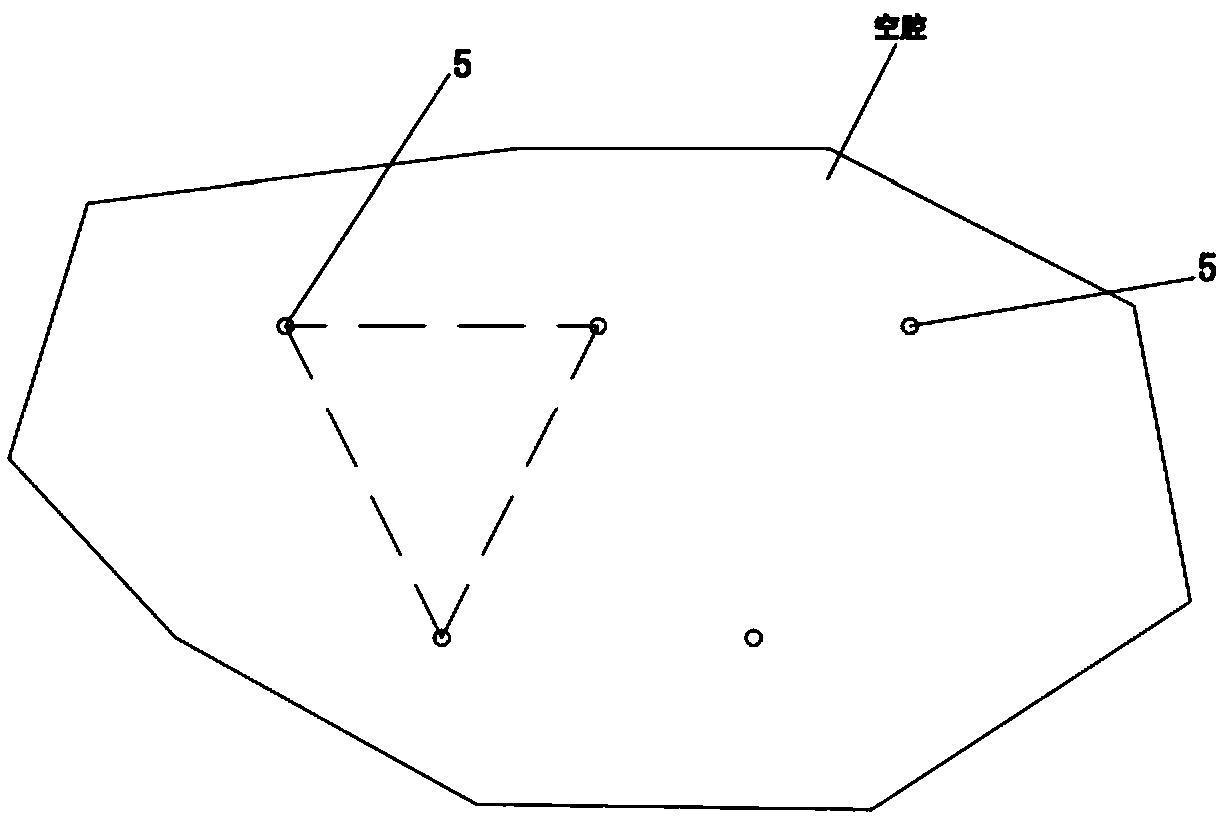

[0033] b. Determine the grouting area of the small conduit in the planned cavity or undense part, dig a 40×40cm second lining concrete 4, and the second lining concrete 4 communicates with the cavity or undense part, and be careful not to damage the waterproof board 2;

[0034] c. Excavate 40×40cm second-lined concrete 4 in the cavity or non-dense grouting range, arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com