Front air suspension with low chassis and automobile

An air suspension and chassis technology, applied in the direction of suspension, elastic suspension, axle, etc., can solve the problems of difficulty in the layout of four longitudinal thrust rods, loss of business opportunities for OEMs, and high cost, so as to improve the anti-rolling ability , reduce tire wear, hard point compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

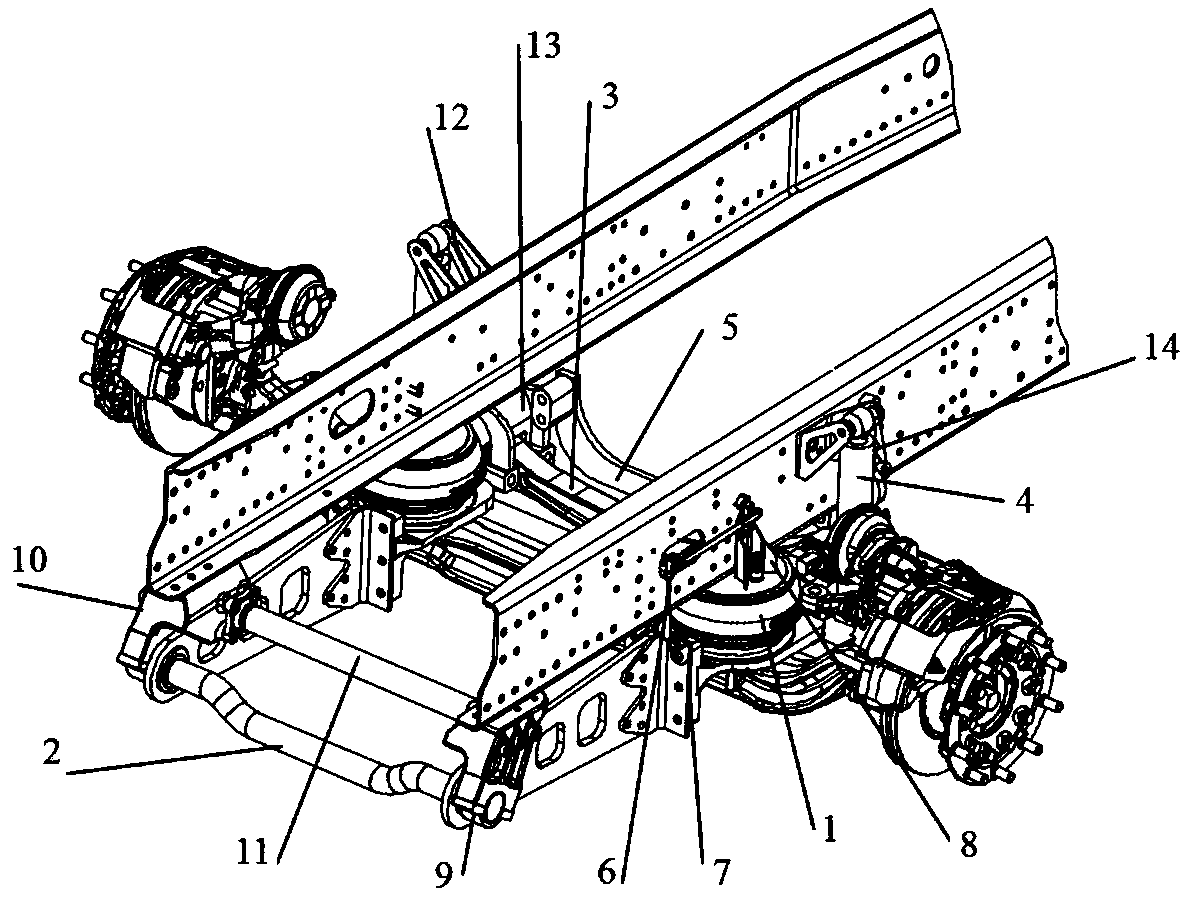

[0055] This embodiment is the basic type of the present invention, and the implementation examples refer to Figure 1-Figure 11 .

[0056] refer to figure 1 , the present invention provides a low-chassis front air suspension, including an air spring 1, a stabilizer bar 2 integrated with a longitudinal bar, a lateral thrust bar 3, and a shock absorber 4.

[0057] The air spring 1 is installed on the underside of the vehicle frame through the air spring and the vehicle frame connection bracket 8, and is mounted on the front axle 15 through the integrated support 7 under the air spring.

[0058] The two ends of the stabilizer bar 2 integrated with the longitudinal bar are connected to the support 7 through the transition bracket 23 , and the middle is assembled with the bracket 10 through the bearing cap 9 .

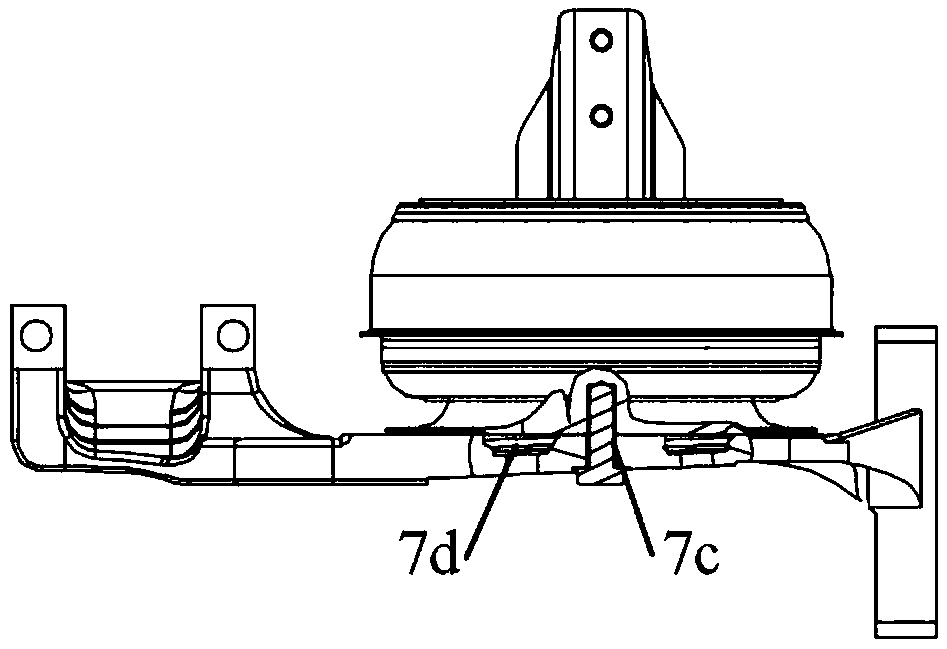

[0059] refer to Figure 2b , the lower end of the shock absorber 4 is connected to the air spring lower integrated bracket 7 through the fourth connecting hole 7d, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com