Oil sunflower deseeding machine capable of reserving oil sunflower disc

An oil sunflower and threshing technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of labor, trouble, and impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

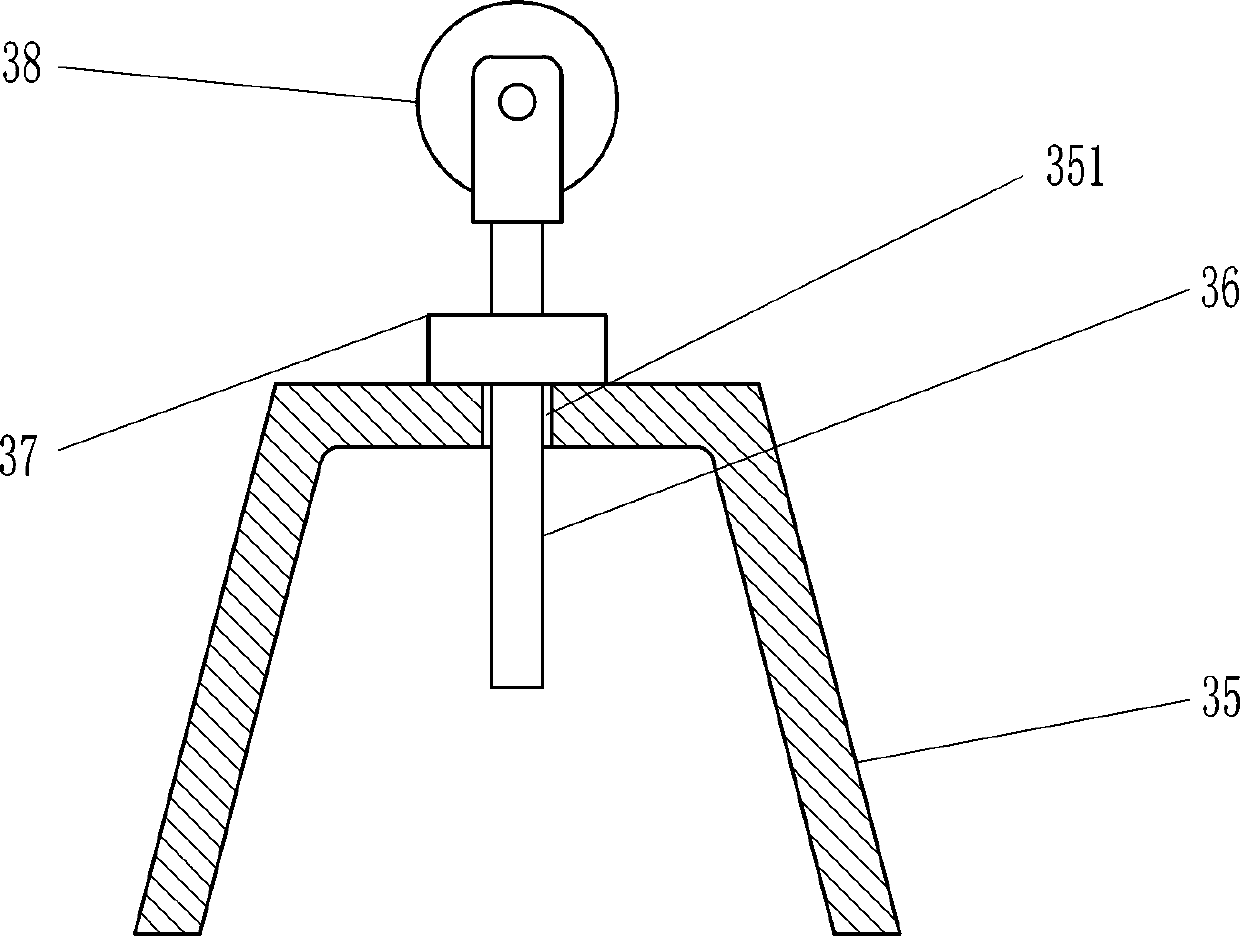

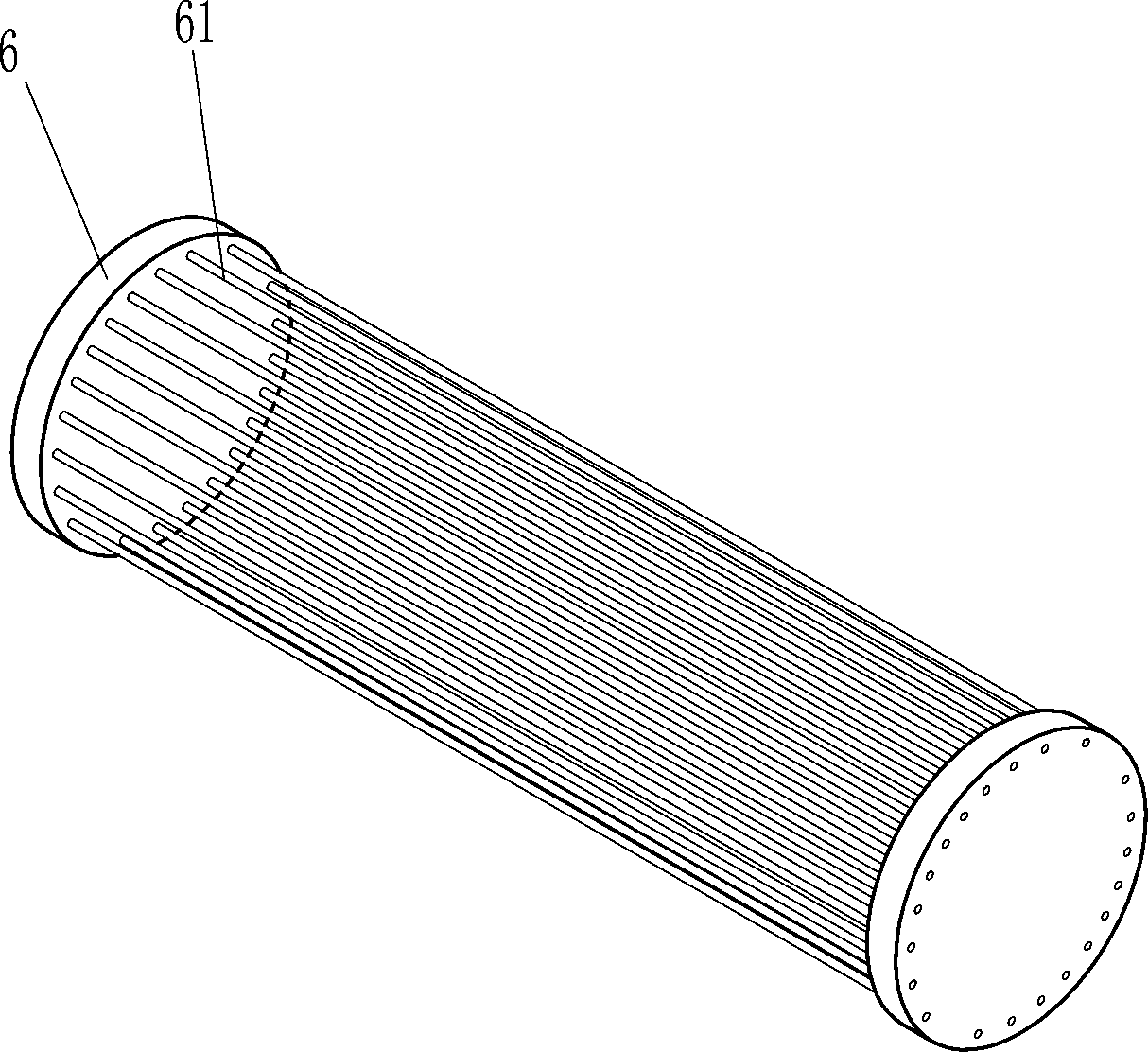

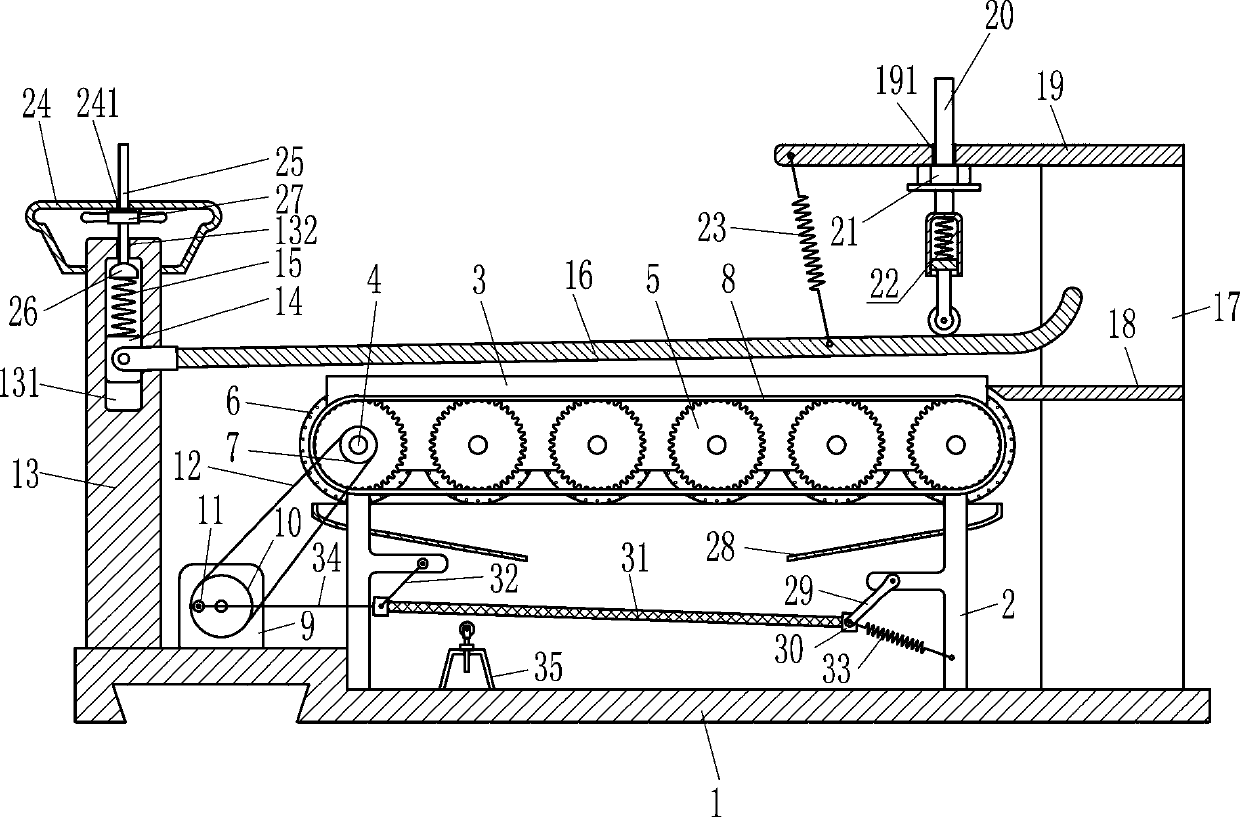

[0017] A kind of oil sunflower deseed machine that can keep the oil sunflower dish, such as Figure 1-3 As shown, it includes a base 1, a first bracket 2, a mounting frame 3, a rotating shaft 4, a sprocket 5, a disc 6, a steel bar 61, a first pulley 7, a chain 8, a motor 9, a second pulley 10, Belt 12, second bracket 13, first slider 14, first spring 15, pressure plate 16, third bracket 17, first flat plate 18, second flat plate 19, first screw rod 20, first nut 21, buffer device 22 and the first extension spring 23, the left and right sides of the top of the base 1 are symmetrically provided with the first support 2, and the top of the first support 2 on the left and right sides is provided with a mounting frame 3, and the first support 2 is connected with the installation by means of bolt connection. The frame 3 is connected, and there are many rotating shafts 4 evenly distributed on the mounting frames 3 on the front and rear sides. The rotating shaft 4 is connected to the ...

Embodiment 2

[0019] A kind of oil sunflower deseed machine that can keep the oil sunflower dish, such as Figure 1-3 As shown, it includes a base 1, a first bracket 2, a mounting frame 3, a rotating shaft 4, a sprocket 5, a disc 6, a steel bar 61, a first pulley 7, a chain 8, a motor 9, a second pulley 10, Belt 12, second bracket 13, first slider 14, first spring 15, pressure plate 16, third bracket 17, first flat plate 18, second flat plate 19, first screw rod 20, first nut 21, buffer device 22 With the first extension spring 23, the left and right sides of the top of the base 1 are symmetrically provided with the first support 2, and the top of the first support 2 on the left and right sides is provided with a mounting frame 3. A rotating shaft 4, the rotating shaft 4 is rotationally connected with the mounting frame 3, the rear end of the front rotating shaft 4 and the front end of the rear rotating shaft 4 are connected with a disc 6, and there are many steel bars 61 connected between ...

Embodiment 3

[0022] A kind of oil sunflower deseed machine that can keep the oil sunflower dish, such as Figure 1-3 As shown, it includes a base 1, a first bracket 2, a mounting frame 3, a rotating shaft 4, a sprocket 5, a disc 6, a steel bar 61, a first pulley 7, a chain 8, a motor 9, a second pulley 10, Belt 12, second bracket 13, first slider 14, first spring 15, pressure plate 16, third bracket 17, first flat plate 18, second flat plate 19, first screw rod 20, first nut 21, buffer device 22 With the first extension spring 23, the left and right sides of the top of the base 1 are symmetrically provided with the first support 2, and the top of the first support 2 on the left and right sides is provided with a mounting frame 3. A rotating shaft 4, the rotating shaft 4 is rotationally connected with the mounting frame 3, the rear end of the front rotating shaft 4 and the front end of the rear rotating shaft 4 are connected with a disc 6, and there are many steel bars 61 connected between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com