Equipment fault prediction method based on particle swarm optimization support vector regression

A technology of support vector regression and particle swarm optimization, applied in instruments, artificial life, computing, etc., can solve the problems of low prediction accuracy, large deviation of prediction results, and low optimization efficiency of prediction algorithm parameters, so as to improve prediction accuracy and improve optimization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

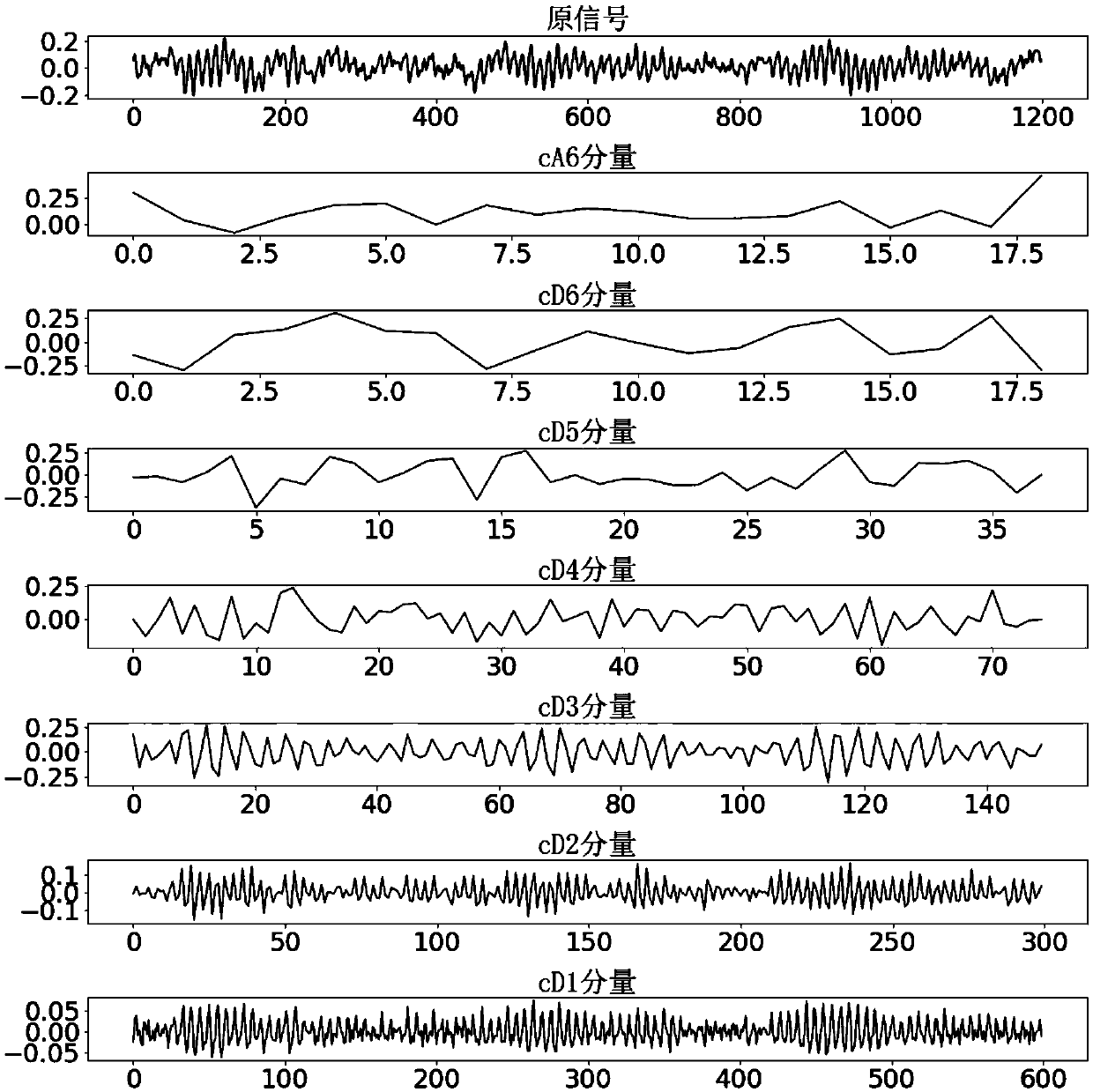

[0044] The data set in Example 1 of the present invention comes from the vibration data of hoist motor bearings in the mining industry, and the vibration data is acquired every 10 minutes. The time window of the vibration data is 1 second, and the sampling rate is 20 kHz. After the following steps, the fault prediction of the motor is carried out:

[0045] Step (1): Use the wavelet decomposition method to extract the features of the vibration signal data of the equipment to be predicted in industrial production.

[0046] The continuous wavelet transform (CWT) formula is:

[0047]

[0048]

[0049] Among them, a is the scale parameter, representing the reciprocal of the frequency; b is the translation parameter; f(t) represents the original signal; ψ(t) represents the small mother wave function.

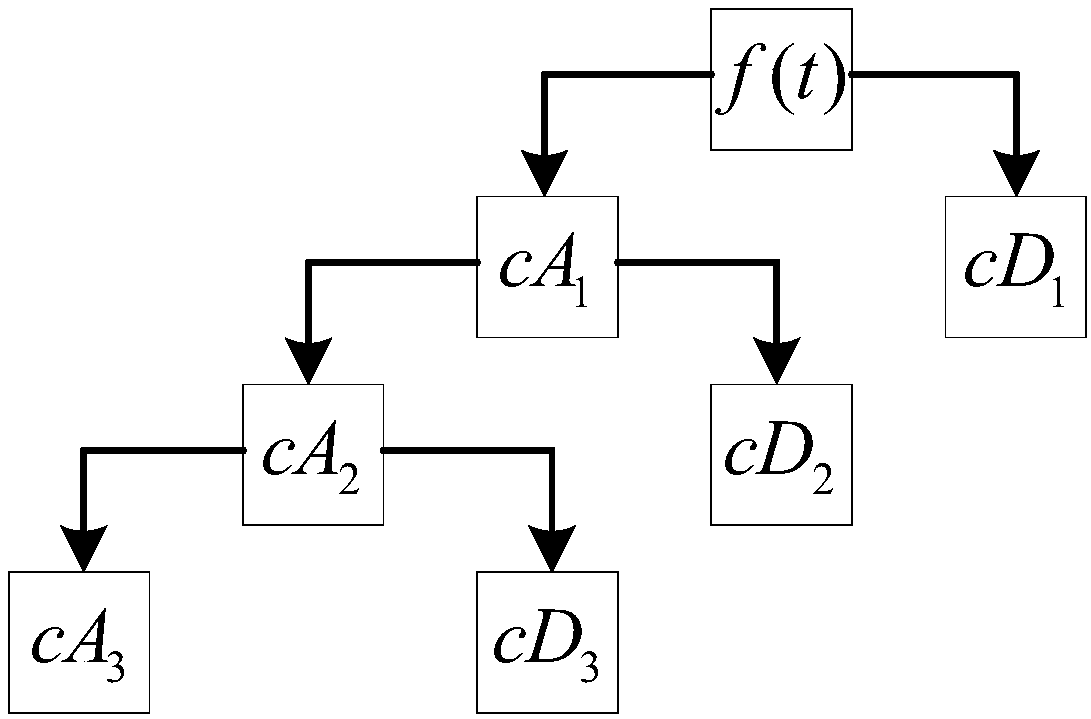

[0050] Since the collected vibration signal is a discrete signal, discrete wavelet transform (discrete wavelet transform, DWT) is performed, and the specific method is:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com