Rotary valve core structure

A rotary and spool technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of poor water control effect, large space occupation, knob damage, etc., to achieve comfortable use, small space occupation, and all-round movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

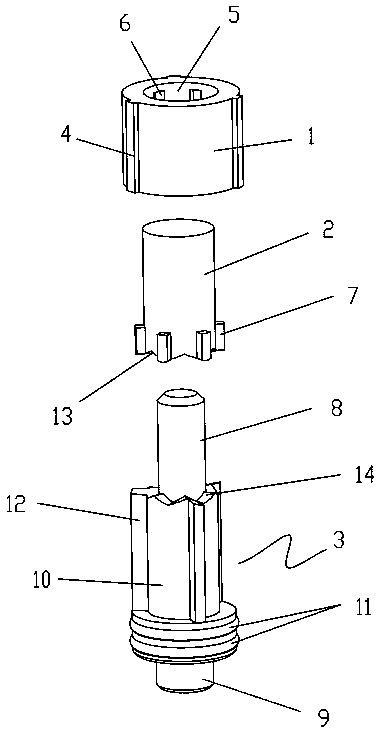

[0010] A rotary valve core structure described in this embodiment 1, such as figure 1 As shown, from top to bottom, it is composed of an upper valve core 1, an inner valve core 2 sleeved in the upper valve core, and a lower valve core 3 partially sleeved and installed with the inner valve core; the outer side of the upper valve core is provided with It is installed in conjunction with the handwheel or handle to drive the upper valve core to the protruding upper clip 4. The upper valve core has an upper valve core cavity 5 that runs through the entire upper valve core along the direction of the central axis. The upper valve core cavity is recessed with Card slot 6; the inner valve core is a columnar structure and the lower part is provided with a middle clip 7 which is fitted with the card slot, and the inner valve core is provided with a unilaterally closed inner valve core cavity from the bottom to the upper direction (not shown in the figure), The inner valve core passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com