Guiding pressing-assembling and detecting device for special-shaped seal ring

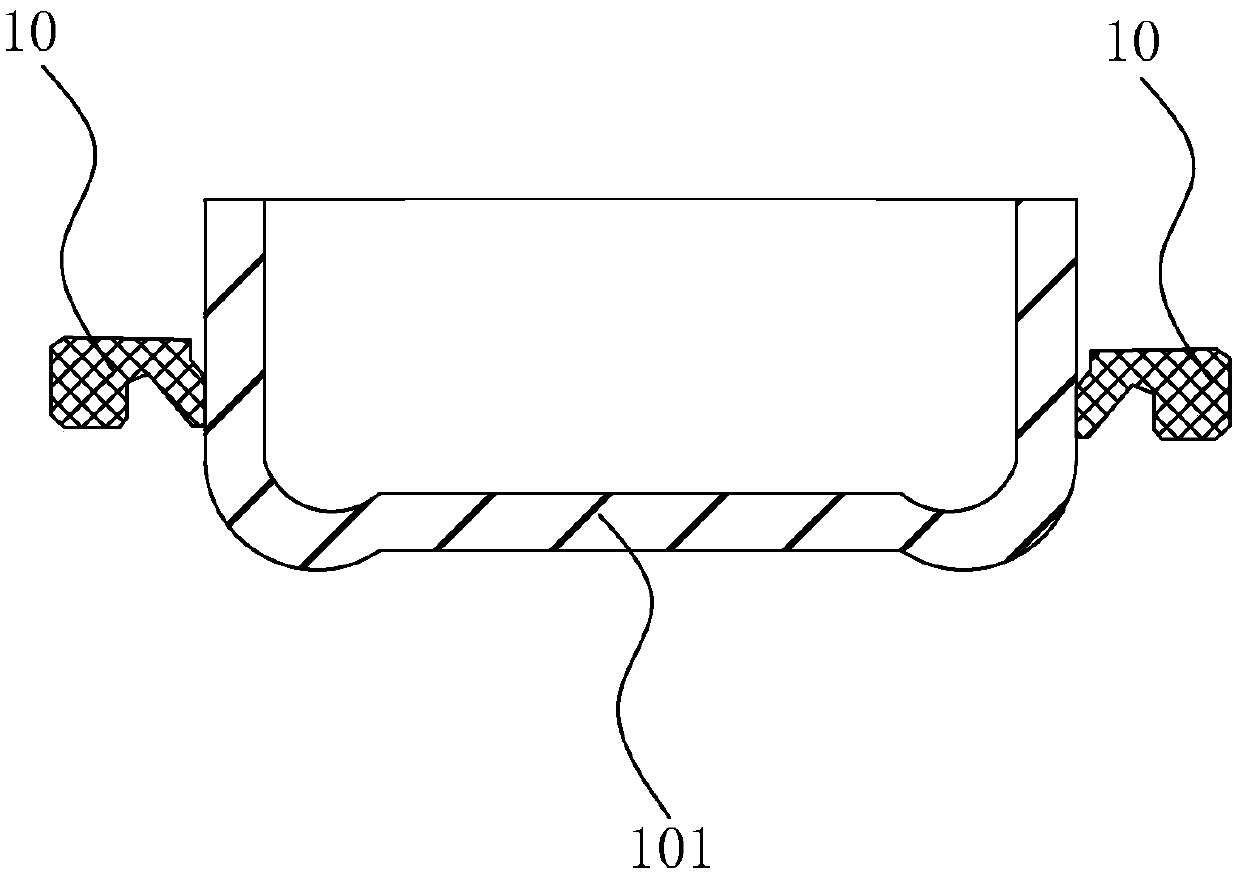

A special-shaped sealing ring, detection device technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of low efficiency of manual assembly, assembly failure, easy to flang up, etc., to achieve real-time monitoring of installation results, improve assembly The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

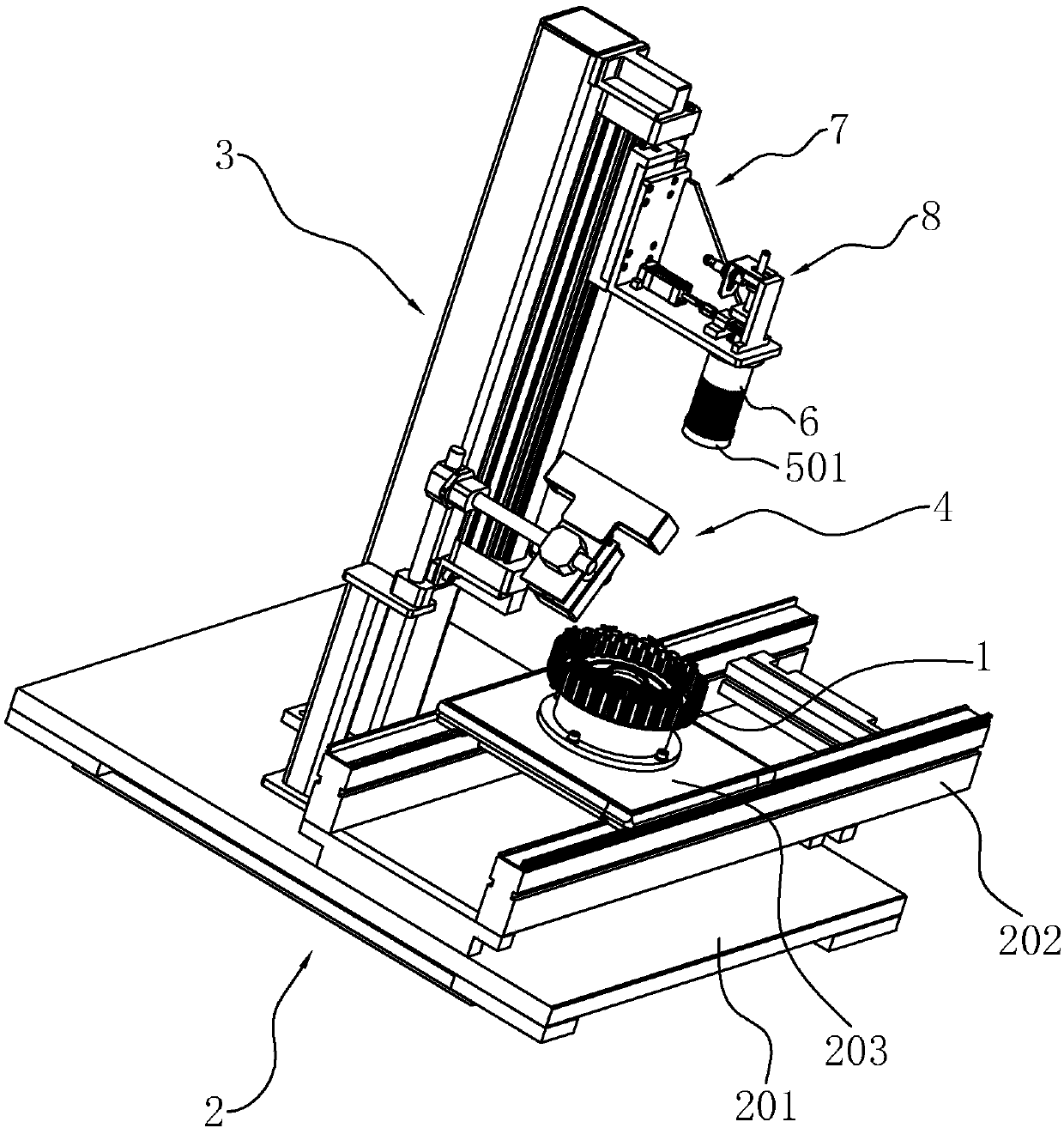

[0033] Example: such as figure 2 As shown, it is a guide press-fitting and testing device for a special-shaped sealing ring disclosed in the present invention, which includes a console 2, a guide press-fitting device 3 fixedly connected to the console 2, and a detection device 4 fixedly connected to the console 2. The operating platform 2 includes a workbench 201 , a conveyor belt 202 connected to the workbench 201 and a boss 203 connected to the conveyor belt 202 for placing the clutch 1 . The clutch 1 is placed on the boss 203 , and along with the transmission of the conveyor belt 202 , the clutch 1 is transferred to the construction position of the workbench 201 .

[0034] like image 3 As shown, a fixed block 204 is added on the boss 203 , and the end of the fixed block 204 away from the boss 203 is provided with a connecting groove 205 matching with the outer teeth of the clutch 1 . The clutch 1 is placed on the boss 203 , and the fixed block 204 cooperates with the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com