A self-cleaning chemical material recovery equipment

A recovery equipment and self-cleaning technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of waste of economical chemical materials, etc., and achieve the effect of improving stirring efficiency and improving automatic cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

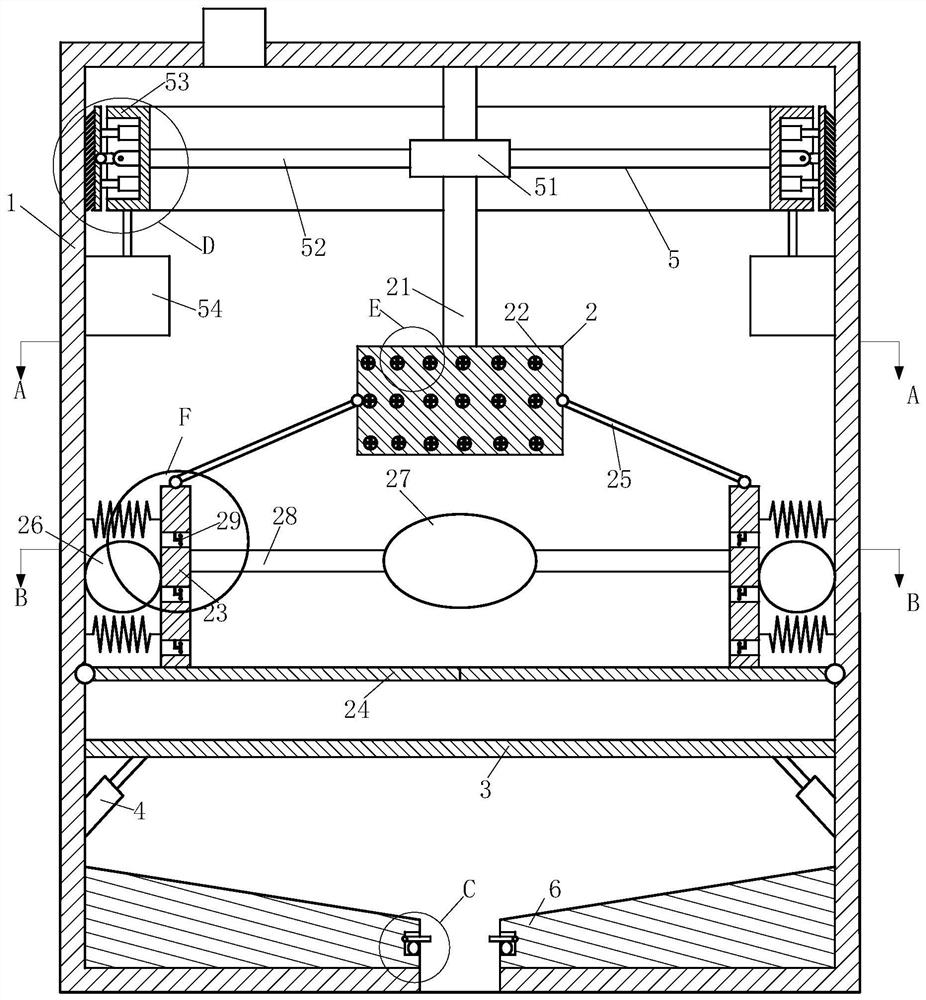

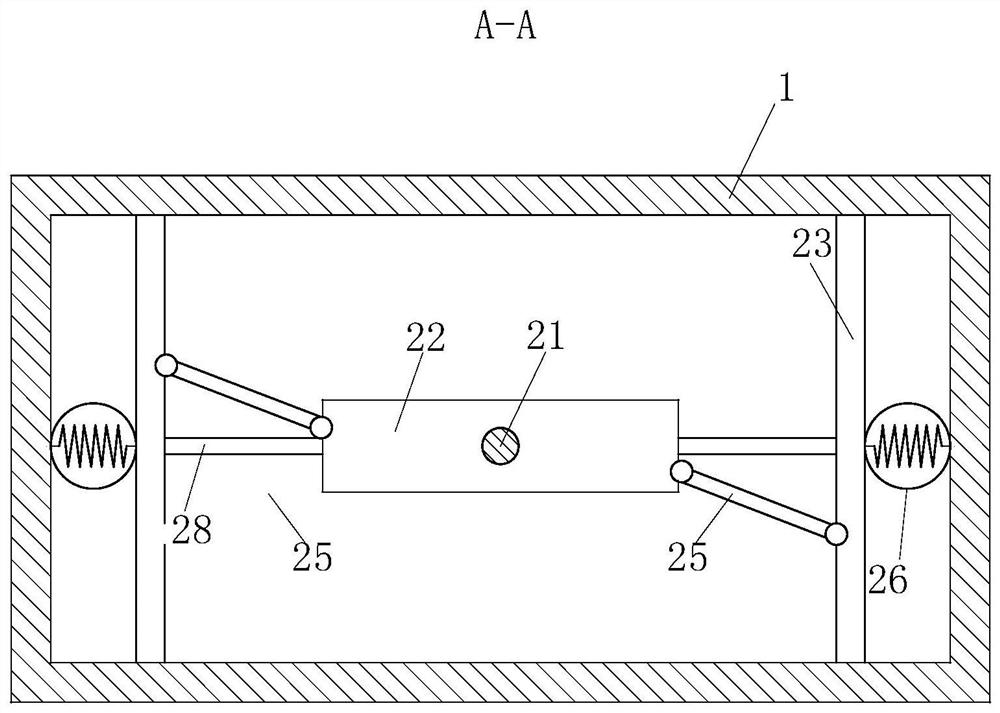

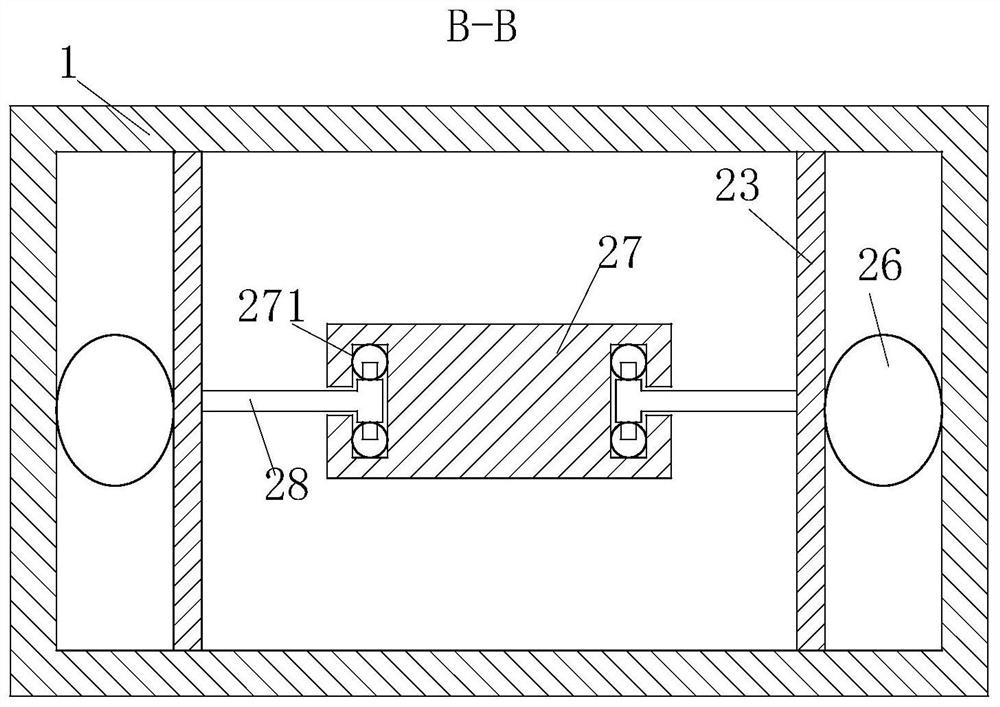

[0027] As an embodiment of the present invention, the cleaning unit 5 includes a ring 51, a No. 3 fixed shaft 52, a brush 53 and a cleaning block 54; the ring 51 is sleeved on the No. 1 fixed shaft 21, and the inner wall of the ring 51 There are threads, and the threads on the inner wall of the ring 51 engage with the threads on the No. 1 fixed shaft 21; there are two No. 3 fixed shafts 52, and the No. 3 fixed shafts 52 are symmetrically distributed on both sides of the ring 51. One end of the shaft 52 is fixedly connected with the side wall of the ring 51, and the other end is fixedly connected with the scrub brush 53; the scrub brush 53 is a square frame, and the scrub brush 53 lower end is fixedly connected with the cleaning block 54 through the fixed shaft; the cleaning block 54 is two The cleaning blocks 54 are symmetrically distributed on both sides of the reaction box 1, and the cleaning blocks 54 can clean the side walls of the reaction box 1. When working, the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com