Device and method for detecting symmetry degree of palm end of roller

A detection device and technology of symmetry, applied in the field of steel manufacturing, can solve the problems of difficult control of details, low precision and inability to perform accurate detection, etc., and achieve the effects of easy batch acceptance, no calculation, and scientific and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

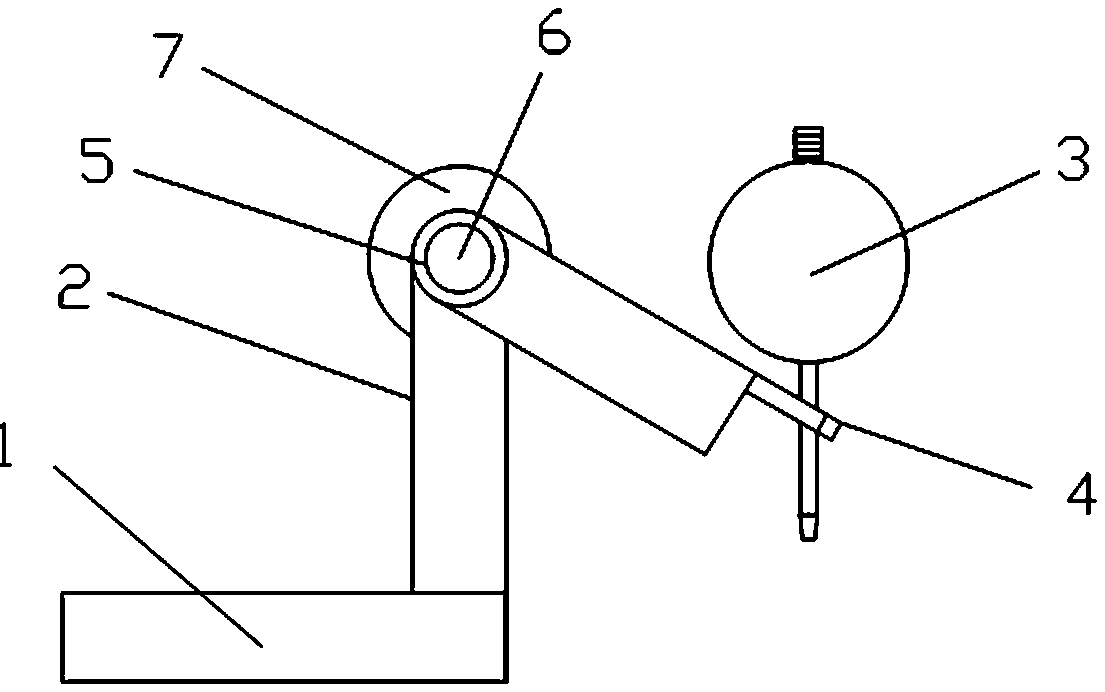

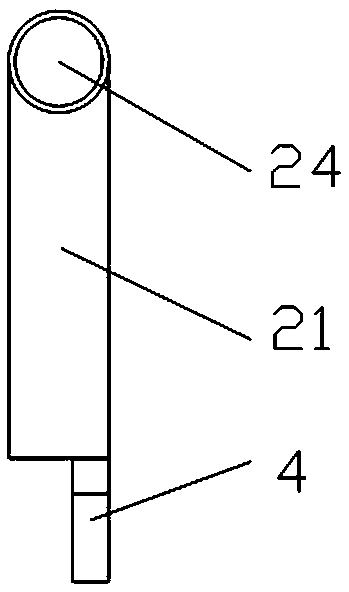

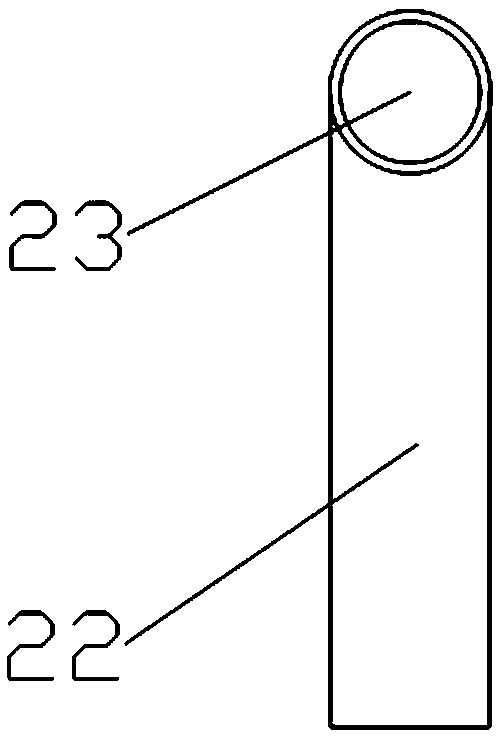

[0024] Such as figure 1 A roll flat head symmetry detection device shown includes a base 1, a rotatable and locked bracket 2 fixed on the base 1, and a dial indicator 3 fixed at the end of the bracket; the bracket 2 includes a tubular upper Support 21 and tubular lower support 22, one end of the lower support 22 is fixed to the base 1, and the other end has a No. 1 through hole 23; one end of the upper support 21 has a No. 2 through hole 24 with the same diameter as the No. 1 through hole 23, The other end fixes the dial indicator 3 through the fixture 4 fixedly connected with it; the No. 1 through hole 23 and the No. 2 through hole 24 run through the rubber tube sleeve 5 with internal thread at the same time, and the inside of the rubber tube sleeve 5 is connected with the internal thread through the internal thread. The screw mandrel 6 is screwed together, and one end of the screw mandrel 6 fixes the rotating handle 7; the clamp 4 is in a 7-shape or N shape, and the clamp 4 ...

Embodiment 2

[0026] Referring to Example 1, the inside of the clamp has a trapezoidal cavity that accommodates the straight rod at the end of the dial indicator.

Embodiment 3

[0028] Referring to Example 1, the base is a square plate of 200*200mm, the length of the upper bracket and the lower bracket shown are the same, both are 200mm, and the cross-sectional diameter of the upper bracket and the lower bracket is 50mm.

[0029] Example 3:

[0030] Such as image 3 The detection method for the symmetry of the flat head of the roll shown is: make the whole roll vertical to the ground, keep the flat head of the roll perpendicular to the ground at the same time; fit the bottom surface of the base of the detection device to the flat side of the flat head of the roll, and rotate the upper bracket so that After the sub-meter head touches the outer circle of the roll neck, the operator manipulates the rotary handle to screw the screw and the rubber sleeve to fix the upper and lower brackets, and at the same time fix the dial indicator head. The operator stands on the roll Roll neck end face side translation detection device, when the detection device moves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com