A kind of imitation active adhesive composition and preparation method thereof

A technology of imitation of reactive and adhesive, applied in dyeing, textile and papermaking, etc., can solve the problems of lack of specific data to explain the effect of low temperature treatment, unclear results, and the inability to satisfy both the fastness and the hand feel, and achieves a high level of improvement. Rubbing fastness, softness improvement, high fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

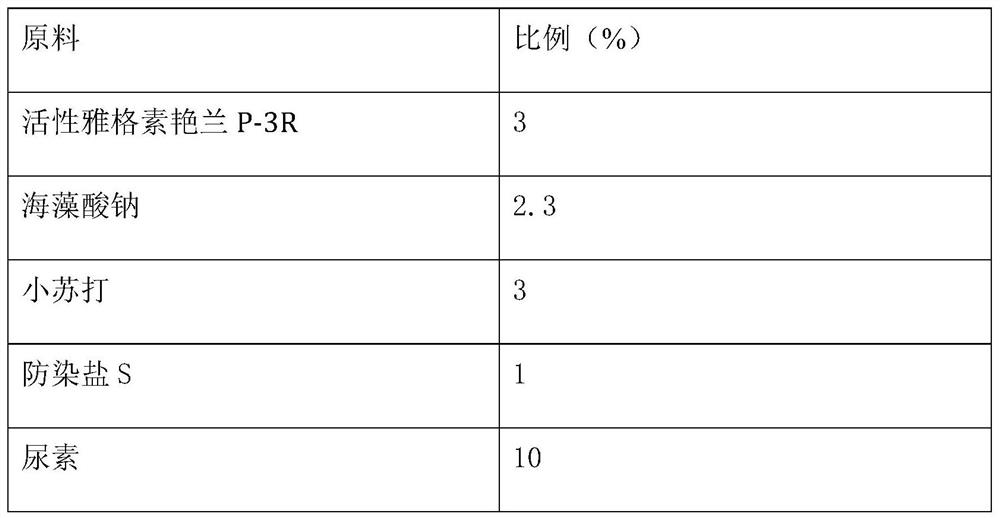

[0062] The formula that present embodiment adopts comprises following raw material:

[0063]

[0064] Another aspect of the present invention provides the preparation method of above-mentioned a kind of novel imitation active adhesive: comprising:

[0065] (1) The preparation method of silicon-acrylic copolymer emulsion 1:

[0066] Silicon-acrylic copolymer emulsion 1 comprises the following components:

[0067]

[0068] Silicon-acrylic copolymer emulsion 1 preparation method:

[0069] First, 1 part by weight of allyl polyoxyethylene ether sulfate (EO=30, NRS-1230, purchased from Shanghai Zhongcheng Chemical Co., Ltd.), 2 parts by weight of allyl polyoxyethylene ether (EO=30, AE-330 , purchased from Shanghai Zhongcheng Chemical Co., Ltd.) mixed with 30 parts by weight of deionized water, heated to 50 ° C, stirred at 80 r / min for 20 min, and obtained 33 parts by weight of an emulsifier solution;

[0070] 5 parts by weight of double-ended vinyl polysiloxane (viscosity 1...

Embodiment 2

[0074]

[0075] Another aspect of the present invention provides the preparation method of above-mentioned a kind of novel imitation active adhesive: comprising:

[0076] (1) The preparation method of silicon-acrylic copolymer emulsion 2:

[0077] Silicon-acrylic copolymer emulsion 2 comprises the following components:

[0078]

[0079] Silicon-acrylic copolymer emulsion 2 preparation method: first 1 weight part of allyl polyoxyethylene ether sulfate (EO=30, NRS-1230, purchased from Shanghai Zhongcheng Chemical Co., Ltd.), 3 weight parts of allyl polyoxyethylene Vinyl ether (EO=30, AE-330, purchased from Shanghai Zhongcheng Chemical Co., Ltd.) was mixed with 30 parts by weight of deionized water, heated to 60° C., stirred at 80 r / min for 20 minutes, and 34 parts by weight of an emulsifier solution was prepared;

[0080] 7 parts by weight of double-ended vinyl polysiloxane (viscosity 200,000 mPa·s, 25°C), 2 parts by weight of acrylonitrile, 1 part by weight of tertiary v...

Embodiment 3

[0084]

[0085] Another aspect of the present invention provides the preparation method of above-mentioned a kind of novel imitation active adhesive: comprising:

[0086] (1) The preparation method of silicon-acrylic copolymer emulsion 3:

[0087] Silicon-acrylic copolymer emulsion 3 comprises the following components:

[0088]

[0089] Silicon-acrylic copolymer emulsion 3 preparation method: 1 weight part of allyl polyoxyethylene ether sulfate (EO=30, NRS-1230, purchased from Shanghai Zhongcheng Chemical Co., Ltd.), 3 weight parts of allyl polyoxyethylene Vinyl ether (EO=30, AE-330, purchased from Shanghai Zhongcheng Chemical Co., Ltd.) was mixed with 30 parts by weight of deionized water, heated to 55 ° C, stirred at 80 r / min for 20 minutes, and 34 parts by weight of an emulsifier solution was obtained;

[0090] 10 parts by weight of double-ended vinyl polysiloxane (viscosity 250,000 mPa·s, 25°C), 2 parts by weight of vinyl acetate, 3 parts by weight of acrylonitrile,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com