Screen processing device and bonding method

A processing device and screen technology, which is applied in the field of screen processing device and bonding, can solve problems such as defective products, flexible film and curved surface protection cover relative contact movement, etc., to achieve the effect of reducing defective products and avoiding air bubbles and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

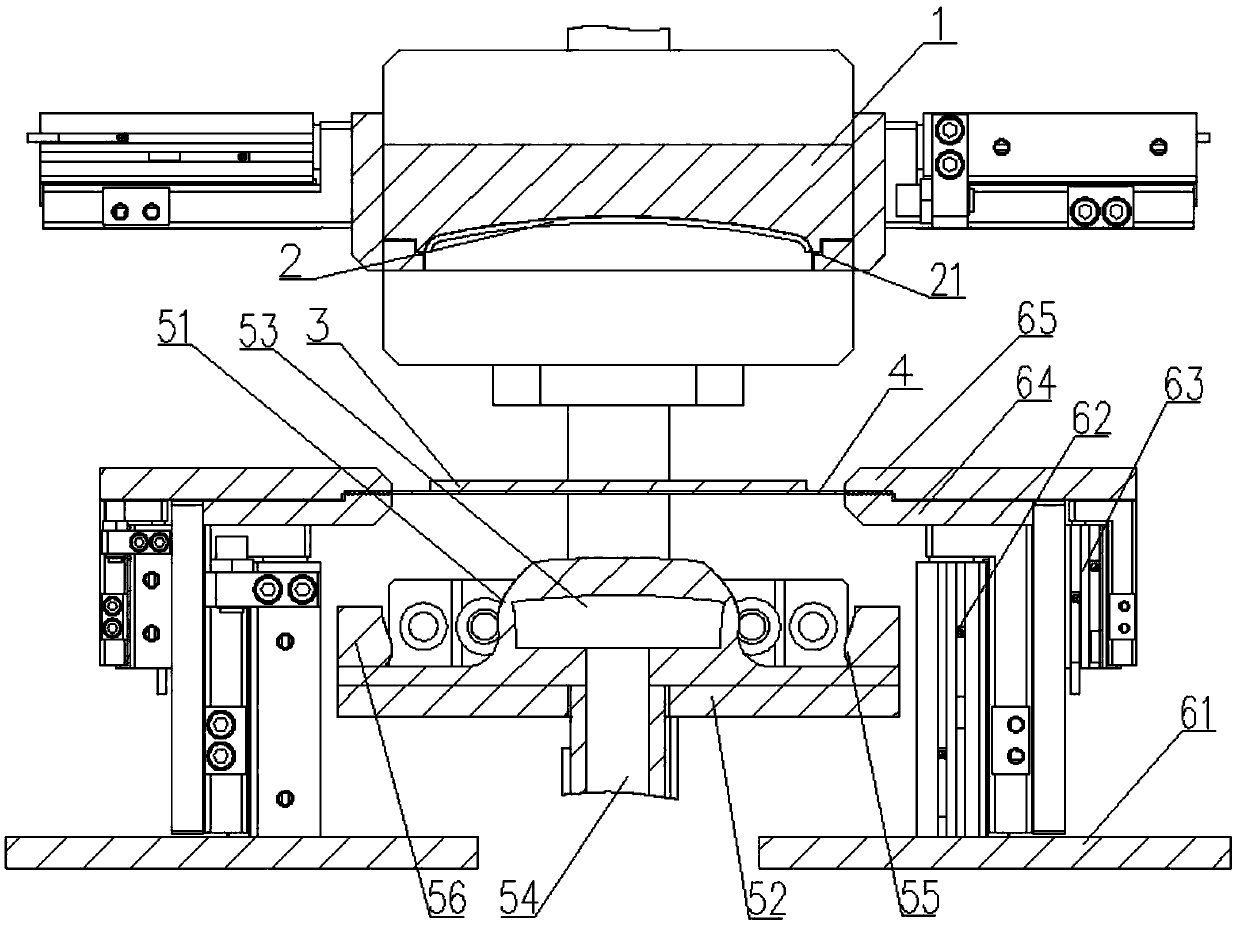

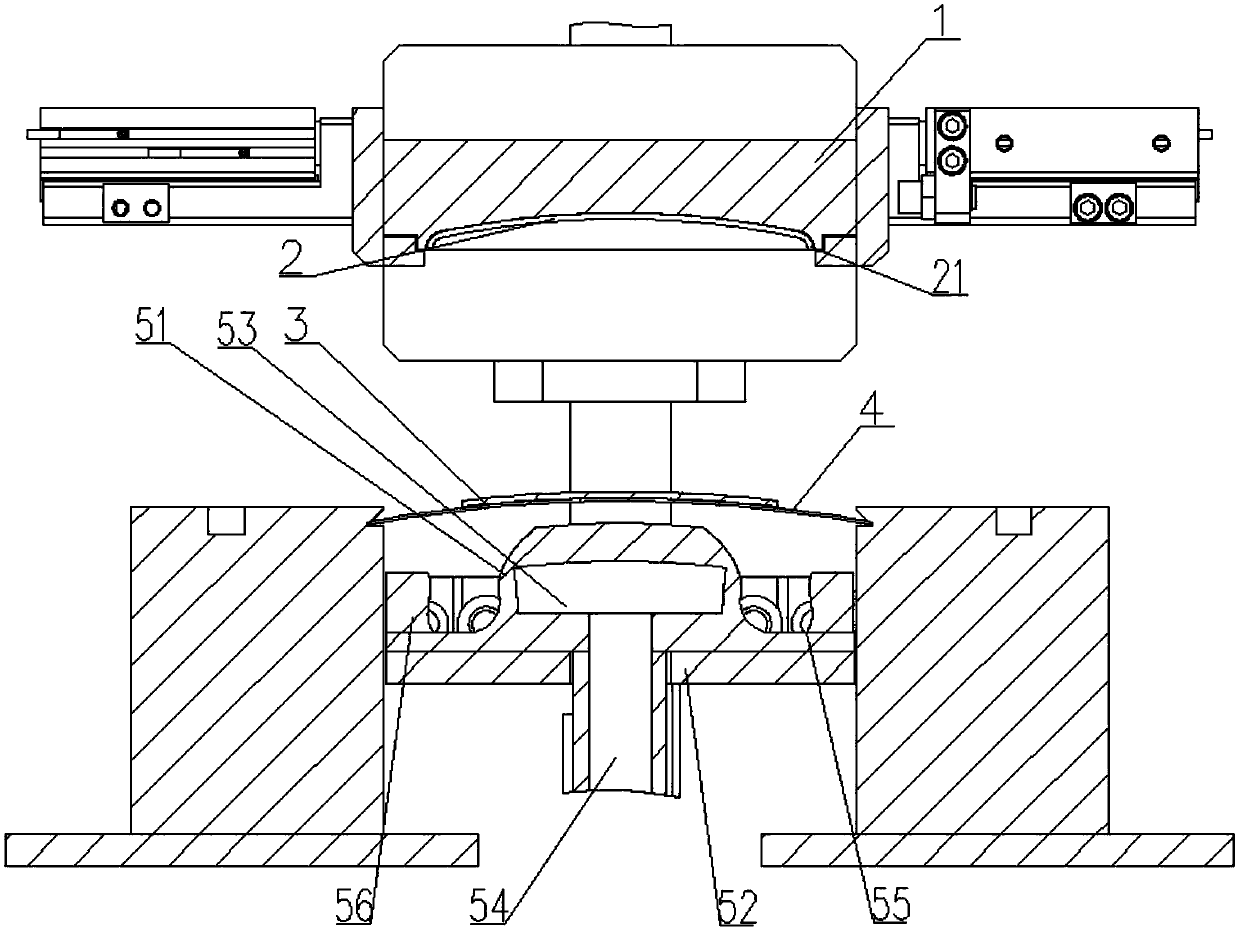

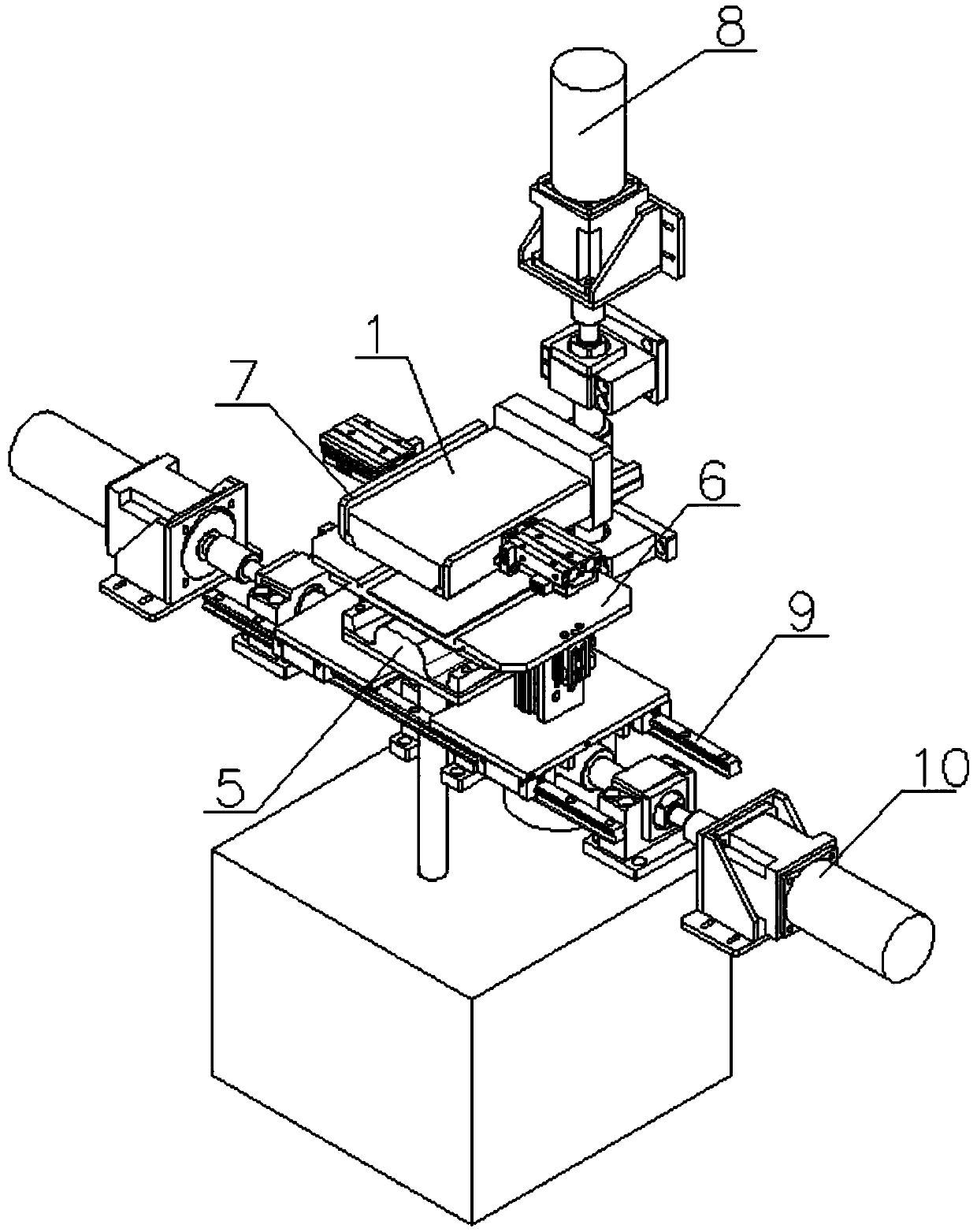

[0039] like Figure 1 to Figure 8 as shown, Figure 1 to Figure 8 The fit and non-fit in are the fit and non-fit between the curved surface protection cover and the flexible film. The screen processing device of the present invention includes an upper cavity and a lower cavity, the upper cavity and the lower cavity are arranged in cooperation, and both the upper cavity and the lower cavity can move up and down; when the When the upper cavity and the lower cavity are closed, a closed space is formed in the upper cavity and the lower cavity; the upper cavity is provided with a placement platform 1 and a curved surface protection cover 2, and the lower cavity is provided with There are a flexible film 3, a carrier tape 4, and a lifting and pressing part 5; the placement platform 1 is used to place the curved surface protection cover 2, the flexible film 3 is placed on the carrier tape 4, and the carrier tape 4 Placed on the lifting and pressing part 5, the flexible film 3 and t...

Embodiment 2

[0047] like Figure 1 to Figure 4 As shown, the placement platform 1 is used to support the curved surface protection cover 2, the placement platform 1 is generally rectangular and has a certain thickness; the placement platform 1 is connected to the lifting device 8 inside the closed space , the placing platform 1 can be moved down toward the lifting and pressing part 5 through the lifting device 8 . The pressing block 51 is arranged on the upper part of the lifting and pressing part 5 ; the height of the pressing block 51 can be adjusted through the lifting and pressing part 5 .

[0048] The lower end surface of the placement platform 1 is provided with an installation groove for accommodating the curved surface protection cover 2, so that the support curved surface protection cover 2 can be fixed; The vacuum holes on the surface of the curved protection cover 2 are used for absorbing and supporting the curved protection cover 2 .

[0049] The clamping device is arranged o...

Embodiment 3

[0065] The limiting device 7 includes a fixed plate 71, a limiting plate 72 and a third cylinder 73 arranged on the placing platform 1, the fixing plate 71 is fixed on the placing platform 1, and the limiting plate 72 It is fixedly arranged at the end of the telescopic rod of the third air cylinder 73, and the third air cylinder 73 is fixedly arranged on the fixed plate 71, and the limit plate 72 and the mounting plate 72 can be adjusted through the third air cylinder 73. The relative position of the slot.

[0066] The limiting plate 72 is symmetrically arranged on both sides of the installation groove, that is, the limiting plate 72 corresponds to the setting of the curved edge 21 of the curved surface protection cover, and the bottom end of the limiting plate 71 exceeds the placement position. The bottom end surface of the platform 1 ensures the contact between the limiting plate 71 and the carrier tape 4 , so that the carrier tape 4 maintains a certain bending state.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com