Mobile phone screen rolling pressing device and attaching method

A rolling device, mobile phone screen technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of small distance between curved screen edges, defects, flexible film and curved edge friction movement, etc., to avoid air bubbles Effects of wrinkles, reduction of defective products, and avoidance of prior contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

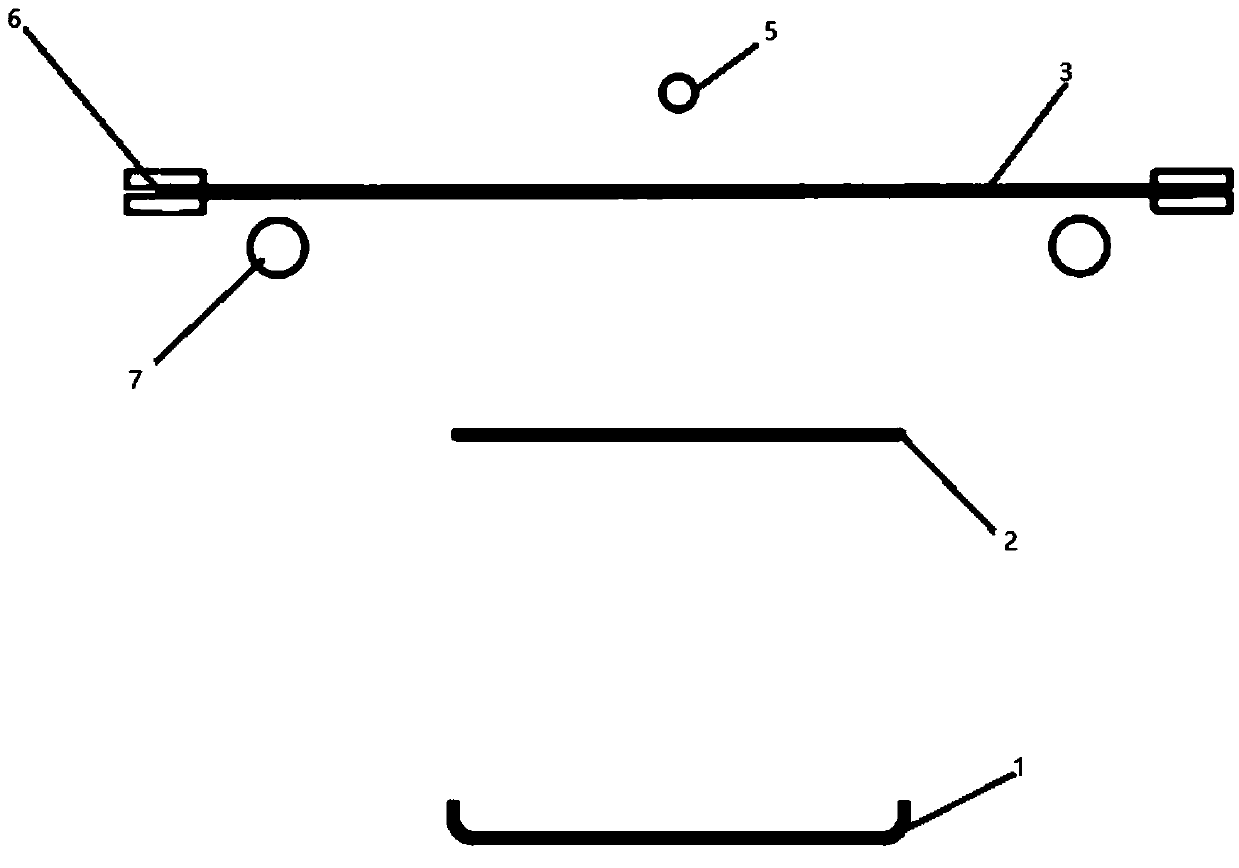

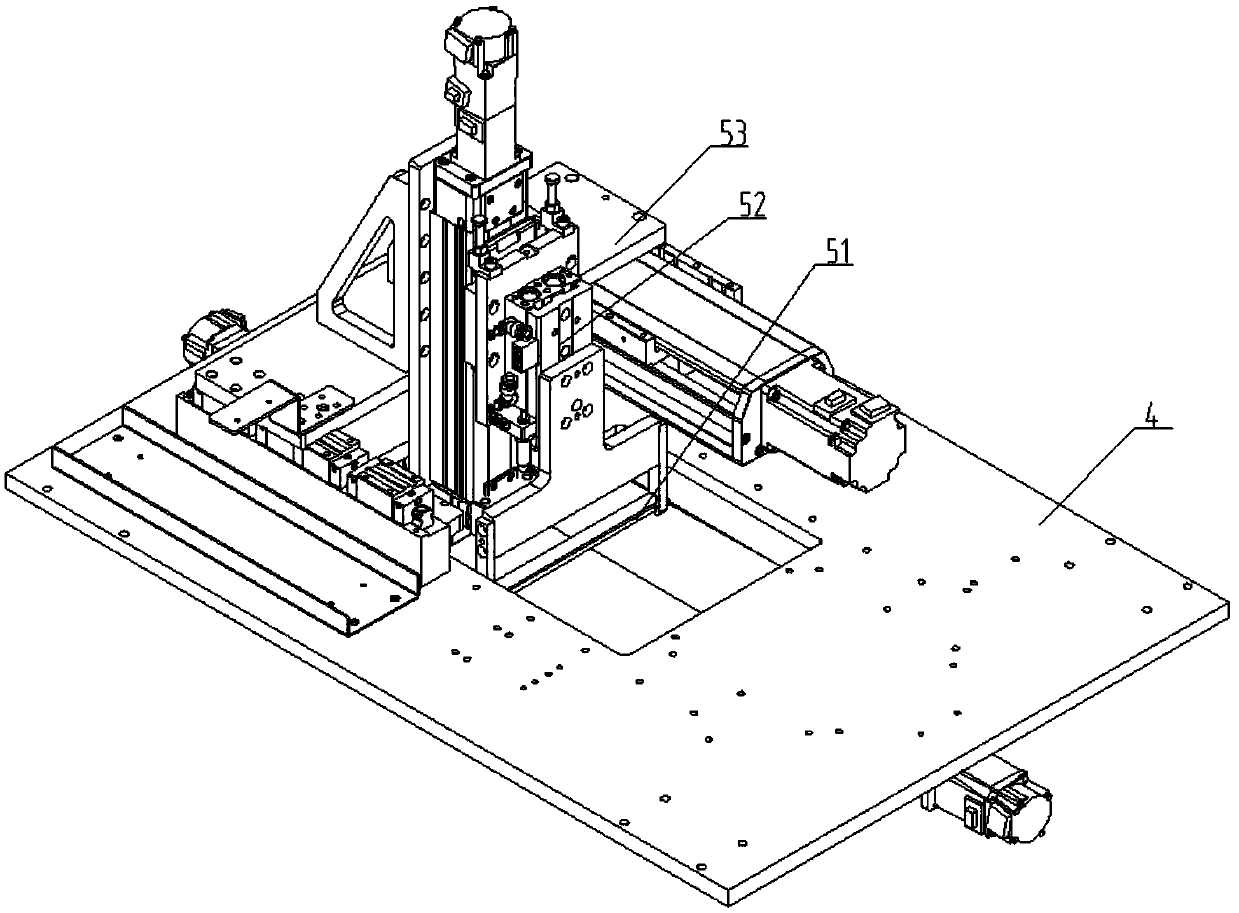

[0035] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the rolling device of the mobile phone screen of the present invention; the rolling device of the mobile phone screen of the present invention includes an upper component and a lower component, the lower component is provided with a flow roller table, and the curved surface protection cover 1 is fixedly arranged on On the flow roller table, the upper assembly is provided with a flexible film 2 and a carrier tape 3; the flexible film 2 is attached to the lower end surface of the carrier tape 3, and the shape of the carrier tape 3 can be changed through the upper assembly In this way, the flexible membrane 2 has an arc shape, the central part of the flexible membrane 2 is at the lowest position and is first attached to the curved surface protection cover 1, and the flexible membrane 2 is gradually moved by the upper assembly. Rolling onto the curved surface protection cover 1 , so as to achieve l...

Embodiment 2

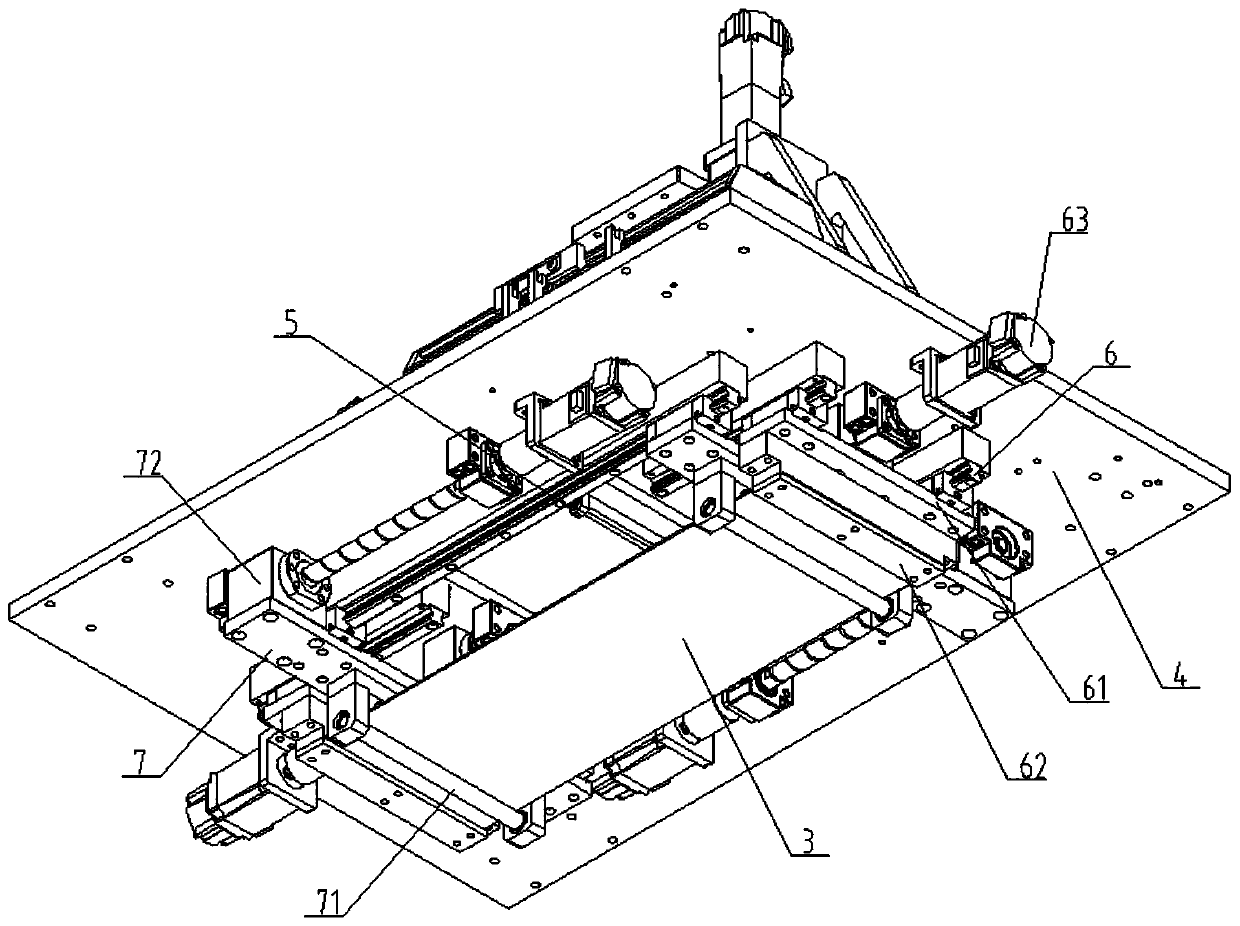

[0045] Preferably, the gripper device 6 includes a gripper base 61, a gripper cylinder and a gripper group 62, and the gripper base 61 is movably connected to two gripper rails; the gripper cylinder and the gripper The clamping groups 62 are all arranged on the clamping base 61, the clamping cylinders are fixedly connected to the clamping groups 62, and the clamping cylinders control the clamping action of the clamping groups 62, that is, through The clamping cylinder can realize the clamping operation of the clamping device 6 on both ends of the carrier tape 3 .

[0046] The gripper base 61 is set in a plate shape with a certain width, and the fitting roller 51 is arranged between the two gripper groups 62, and the gripper base 61 can be moved away from or Close to the fitting roller 51 . One side of the gripper base 61 is provided with a gripper motor 63, the gripper motor 63 is fixed on the mounting plate 4, and the output shaft of the gripper motor 63 corresponds to the g...

Embodiment 3

[0052] Such as Figure 5 as shown, Figure 5 It is a schematic flow chart of the bonding method of the mobile phone screen of the present invention; the bonding method of the mobile phone screen of the present invention comprises the steps of:

[0053] S1, attaching the flexible film 2 to the carrier tape 3, and moving the curved protective cover 1 to directly below the carrier tape 3 through the flow roller table;

[0054] S2, fixing the end of the carrier tape 3 attached with the flexible film 2 by the clamping device 6;

[0055] S3, by moving the position of the clamping group 62 and pressing down the fitting roller 51, the carrier tape 3 forms an arc surface, and the central part of the carrier tape 3 and the curved surface protection cover The central part of 1 is in contact with the fit;

[0056] S4, adjust the limit roller 71, and release the clamping effect of the clamping group 62 on the end of the carrier tape 3, so that the end of the carrier tape 3 overlaps the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com