A prefabricated mold for balcony slabs

A technology of balcony panels and molds, which is applied in the direction of molds, etc., can solve the problems of low mold utilization rate, high production cost, high work intensity, etc., and achieve the effect of convenient disassembly and assembly on site, high mold utilization rate and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

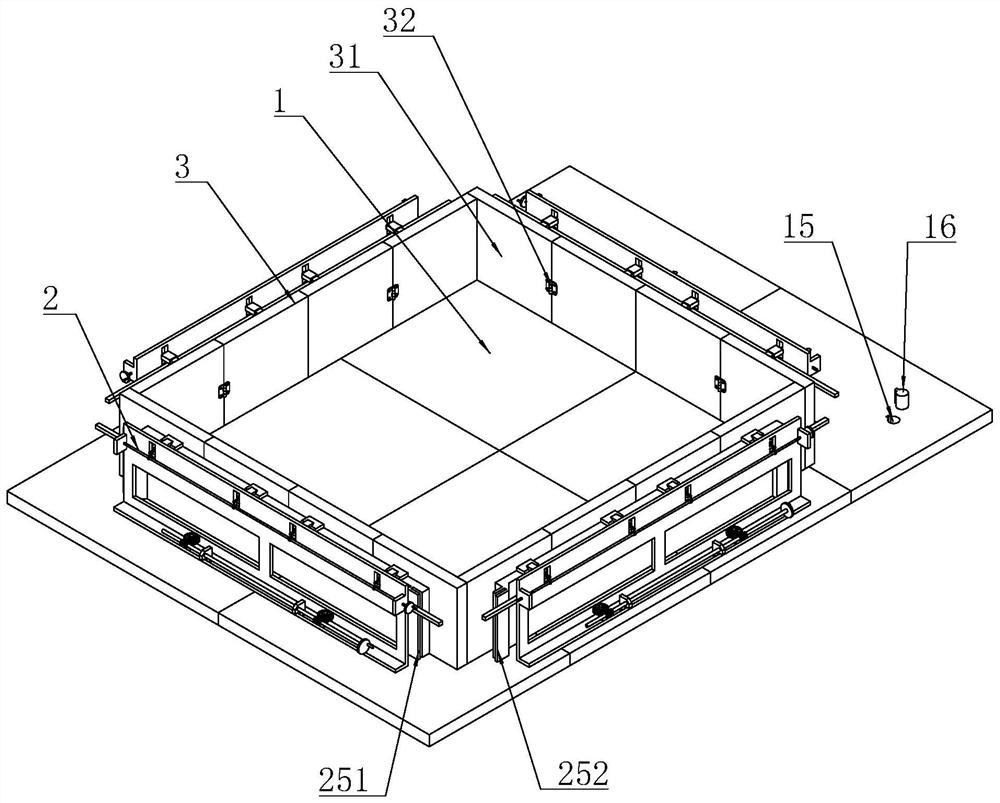

[0040] Embodiment 1: A kind of balcony plate prefabrication mold, such as figure 1 As shown, it includes a base 1, a fence 2 and a fence 3. The fence 2 is erected on the base 1 and forms an external enclosure according to the design of the balcony prefabricated board. cavity.

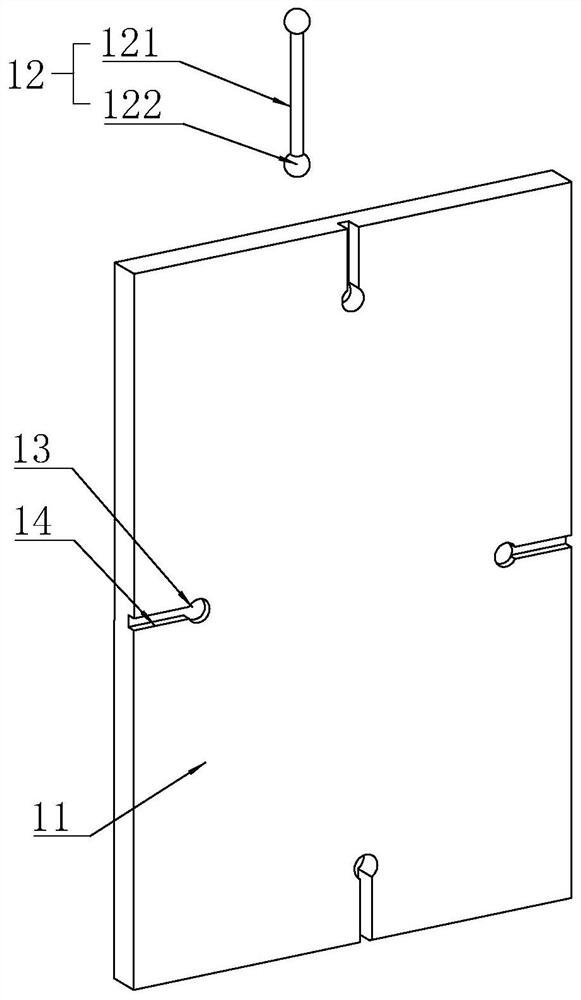

[0041] refer to figure 2 , The base 1 is composed of a plurality of bottom units 11 spliced with each other, and an elastic pad is arranged around the bottom unit 11 . A connecting piece 12 is connected between adjacent bottom units 11, and the connecting piece 12 includes a rod portion 121 and a spherical end 122 whose diameter is larger than that of the rod portion 121. The bottom of the bottom unit 11 is provided with an embedding groove for the spherical end 122 to engage. 13 and the via hole 14 through which the rod portion 121 passes. Different numbers of bottom units 11 can be configured according to actual needs.

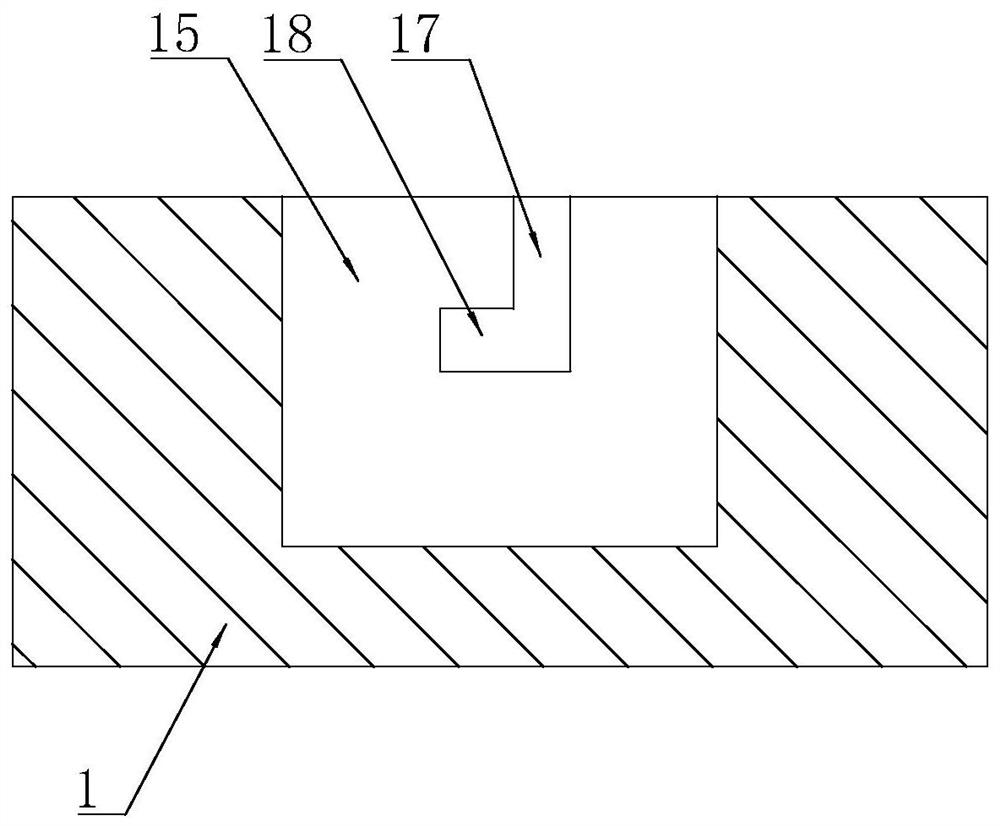

[0042] refer to figure 1 with image 3The upper surface of the bottom un...

Embodiment 2

[0052] Embodiment 2: The difference from Embodiment 1 is that the fence 2 includes an inner fence and an outer fence, and there are a plurality of hinge rods whose two ends are respectively hinged with the inner fence and the outer fence. At least one row of pin shafts 21 are respectively arranged on and on the outer column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com