A method of manufacturing a bracket positioning guide plate

A manufacturing method and technology of brackets, applied in brackets, medical science, dental prosthetics, etc., can solve the problems of bracket positioning guide plate obstruction force, adhesive overflowing bottom plate, bracket positioning inaccuracy, etc., to avoid cleaning Effects of Difficulty, Avoidance of Obstruction, Simple Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

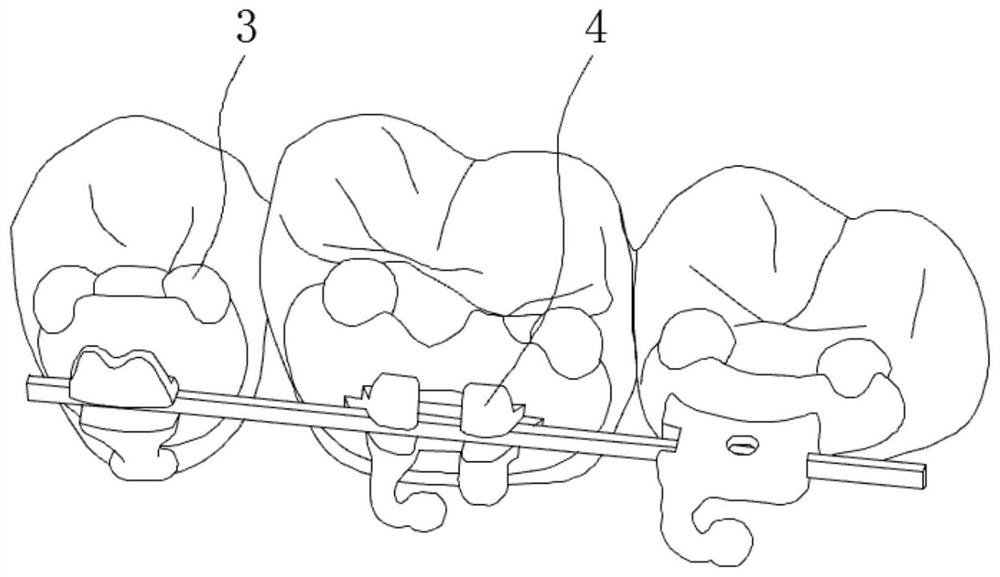

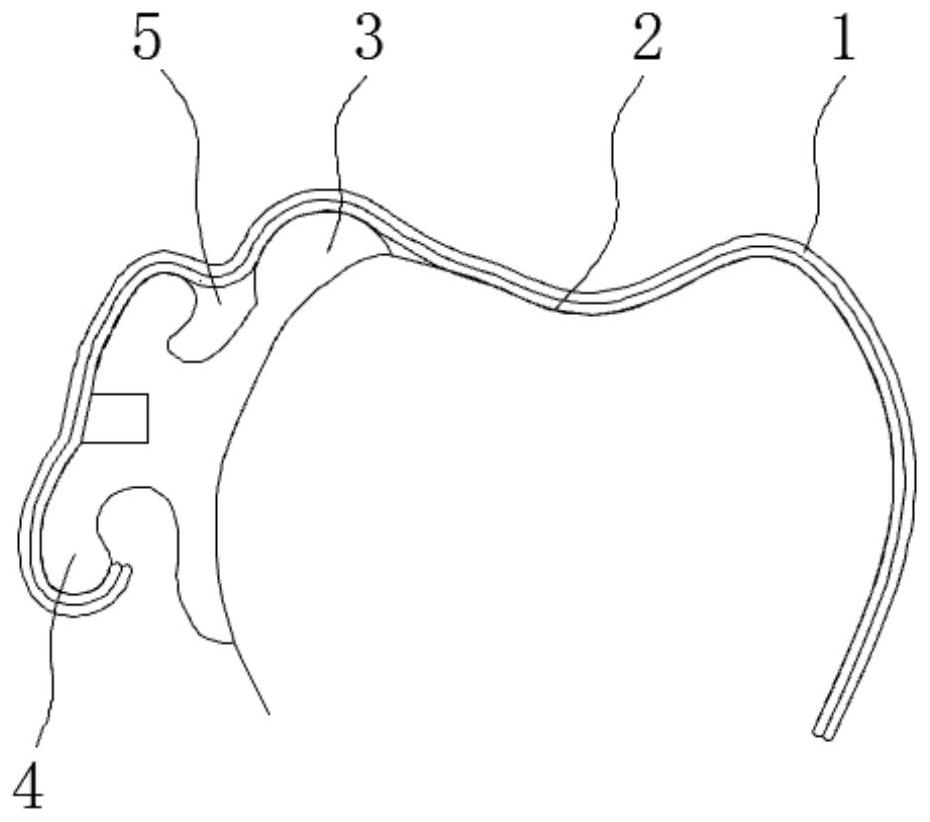

[0024] Please refer to the attached Figure 1-2 , a bracket positioning guide plate in this embodiment, including a hard pressure film 1 for occlusal, a soft pressure film 2 and an air bubble ball 3 that fit the tooth surface, the hard pressure film 1 and the soft pressure film The shape of the quality pressure film 2 is the same, and the hard pressure film 1 and the soft pressure film 2 are completely attached, and the hard pressure film 1 and the soft pressure fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap