Concrete crack making method

A production method and concrete technology, applied in the preparation of test samples, etc., can solve problems such as complexity, difficulty in operation, high cost, and lack of pertinence, and achieve the effects of easy handling, simple and reliable implementation, and good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

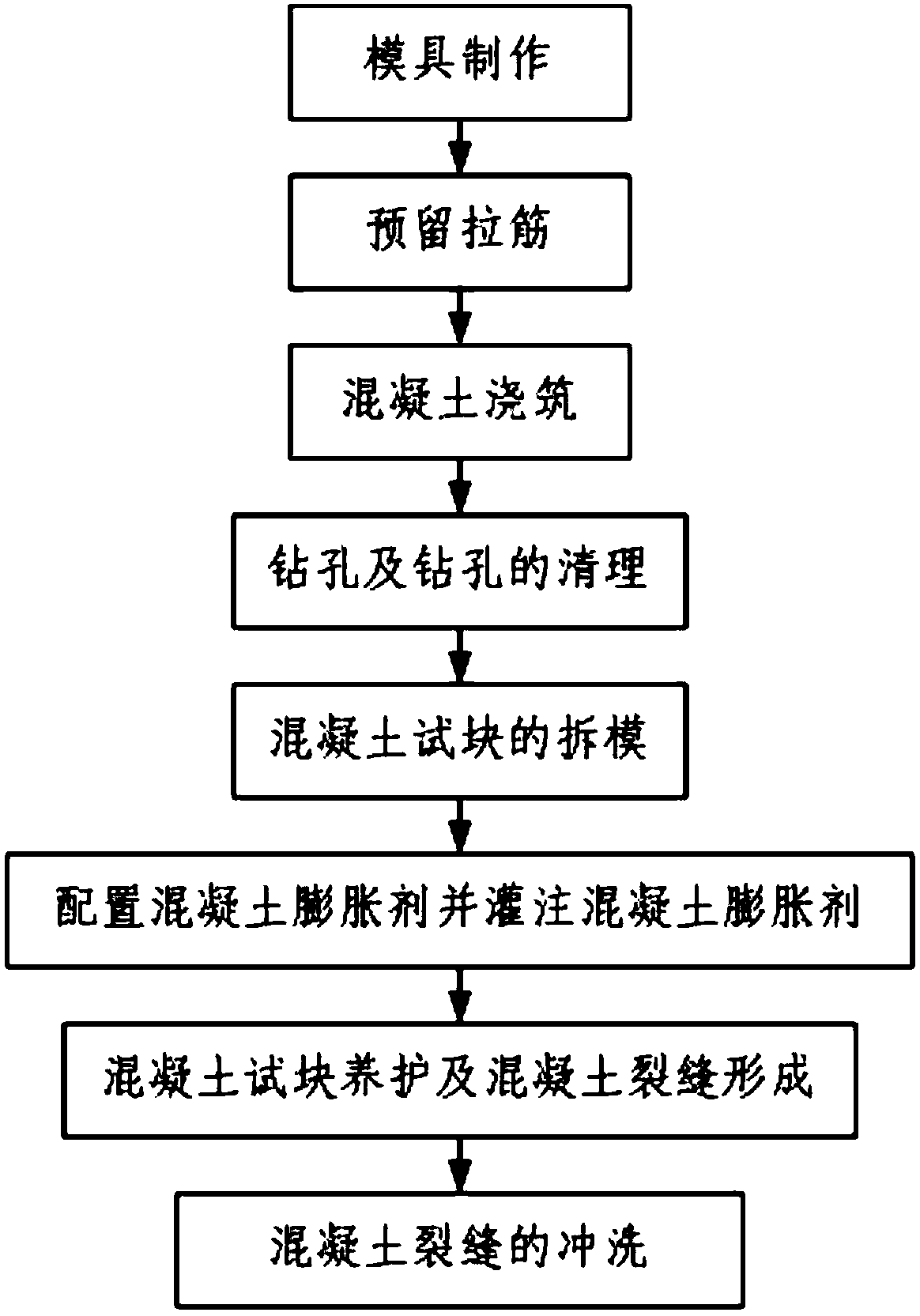

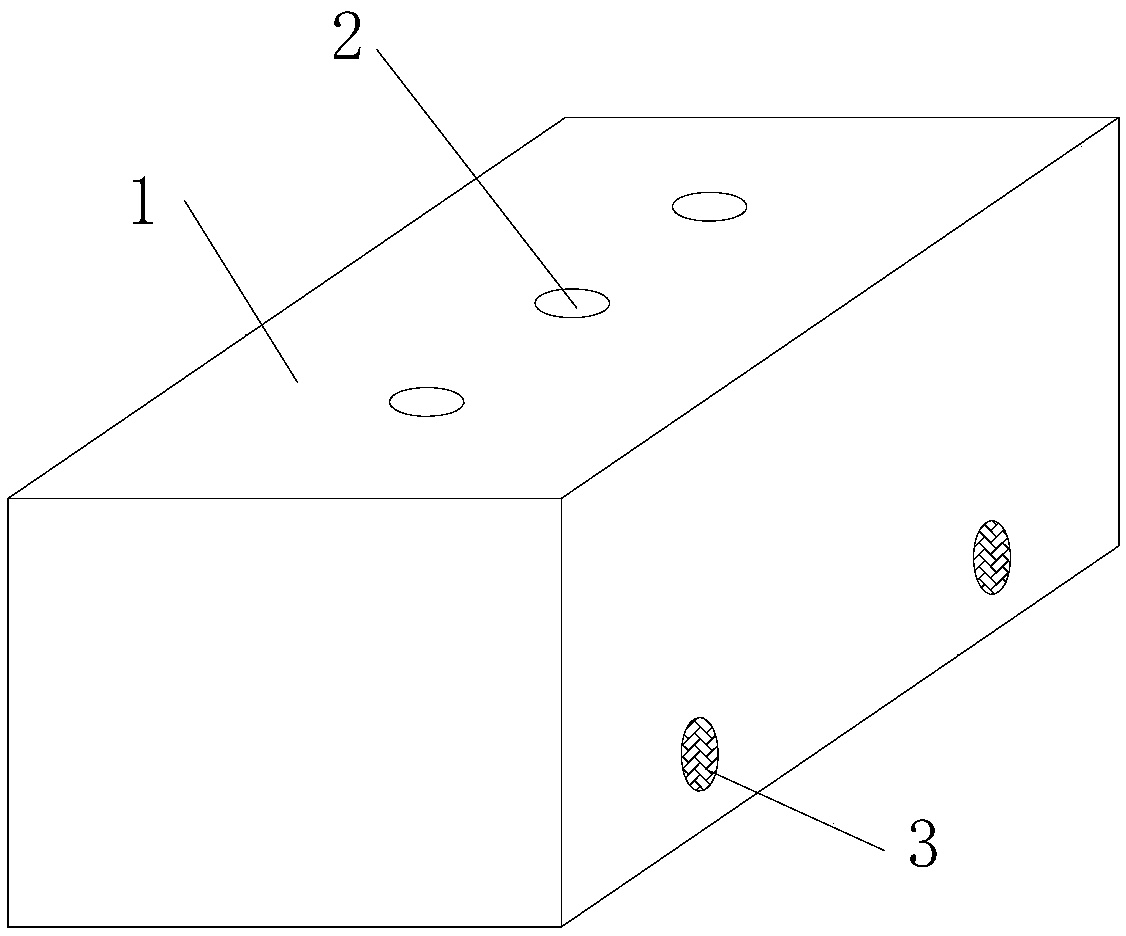

[0033] like Figure 1 to Figure 4 Shown, a kind of concrete crack making method of the present invention comprises the following steps:

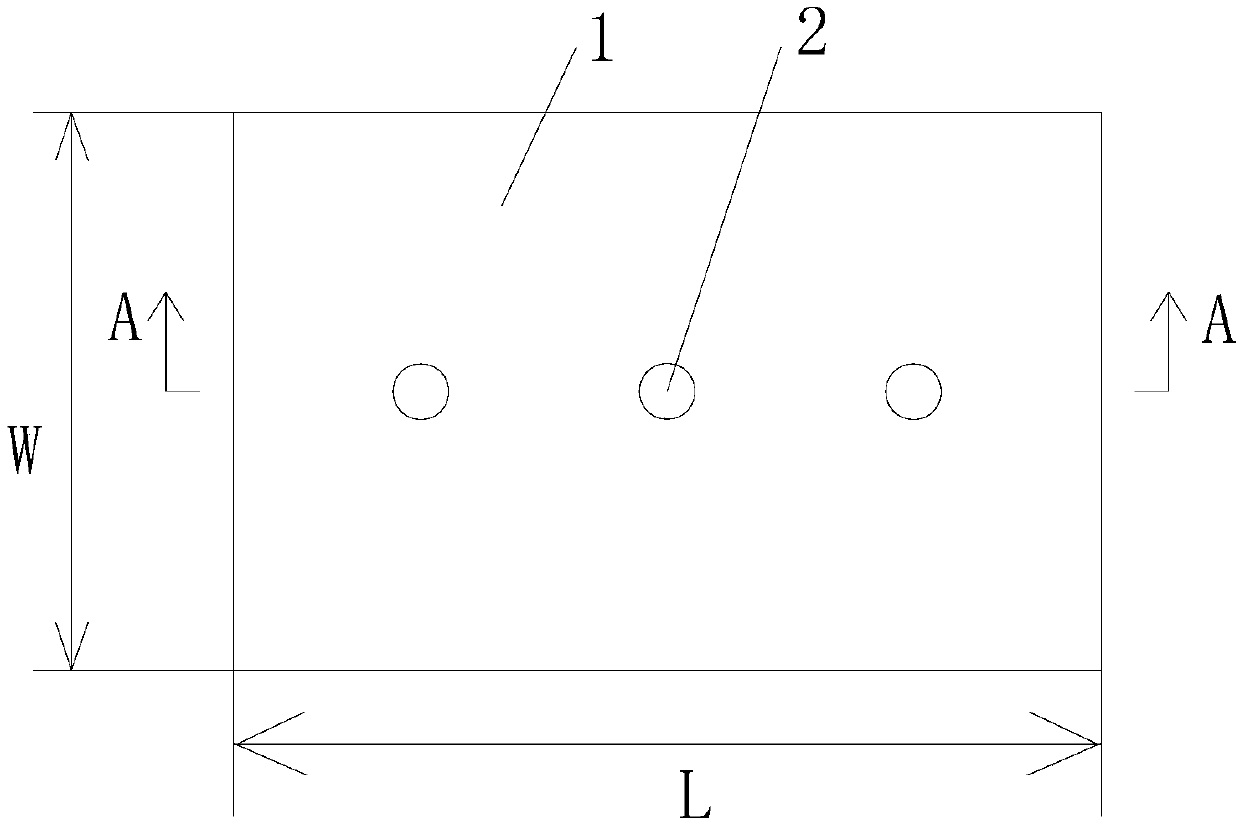

[0034] Step 1, mold making: make a wooden mold without a top plate according to the size of the concrete test block 1 to be made, the size of the wooden mold is greater than the size of the concrete test block 1, the wooden mold is made of planks, and There are two through-hole pairs reserved on the side wall of the mold, the number of the through-hole pairs is two, the central axes of the two through-hole pairs are parallel, and the plane where the two central axes are located is parallel to the horizontal plane. The hole pair includes two through holes with the same size, and the distance β between the lower edge of the through hole in the through hole pair and the inner surface of the wooden mold bottom plate satisfies: 0<β<10cm;

[0035] In this embodiment, the thickness of the wooden board is not less than 4mm, so as to prevent the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com