Gear-adjustment oil filling device for automobile seat skeleton assembling

A technology of car seat frame and oiling device, which is applied in the direction of motor vehicles, transportation and packaging, and engine lubrication, etc. It can solve the problems of long oiling time for gears, reduce labor costs, simplify operating procedures and operating time, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

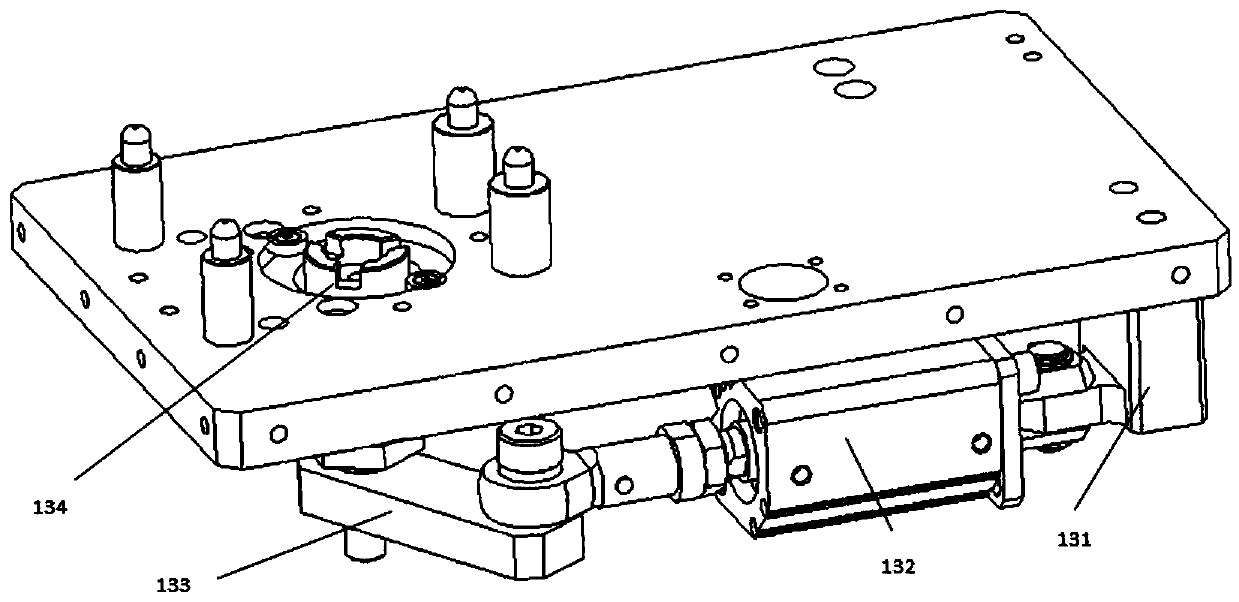

[0029] see figure 1 As shown, the present invention provides a technical solution: a gear adjusting oiling device for automobile seat frame assembly, including a PUMP gear adjusting oiling tool 100, and the PUMP gear adjusting oiling tool 100 includes a sliding mechanism 110, a locking mechanism 120, a gear adjusting Mechanism 130, molding mechanism 140 and oiling mechanism 150, sliding mechanism 110 is installed on the outer frame of PUMP gear adjustment oiling tool 100, and is connected with sliding with outer frame, and locking mechanism 120 is arranged on the top of sliding mechanism 110, to sliding mechanism 110 to limit the position, the tooth adjustment mechanism 130 is installed on the rear end of the sliding mechanism 110 substrate, and is connected to the sliding mechanism 110 in rotation, the die pressing mechanism 140 is placed on the top of the sliding mechanism 110, and is connected with the outer surface of the PUMP tooth adjusting oiling tool 100 The frame is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com