Construction node for H-shaped steel beam hoisting and using method of construction node

A technology of H-shaped steel and structure, which is applied in the direction of building structure, transportation and packaging, and load hanging components, etc. It can solve the problems of hoisting wire wear and fast steel beam hoisting process, so as to achieve less construction measures and reduce hoisting preparation time , Promote the effect of green and environmental protection construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

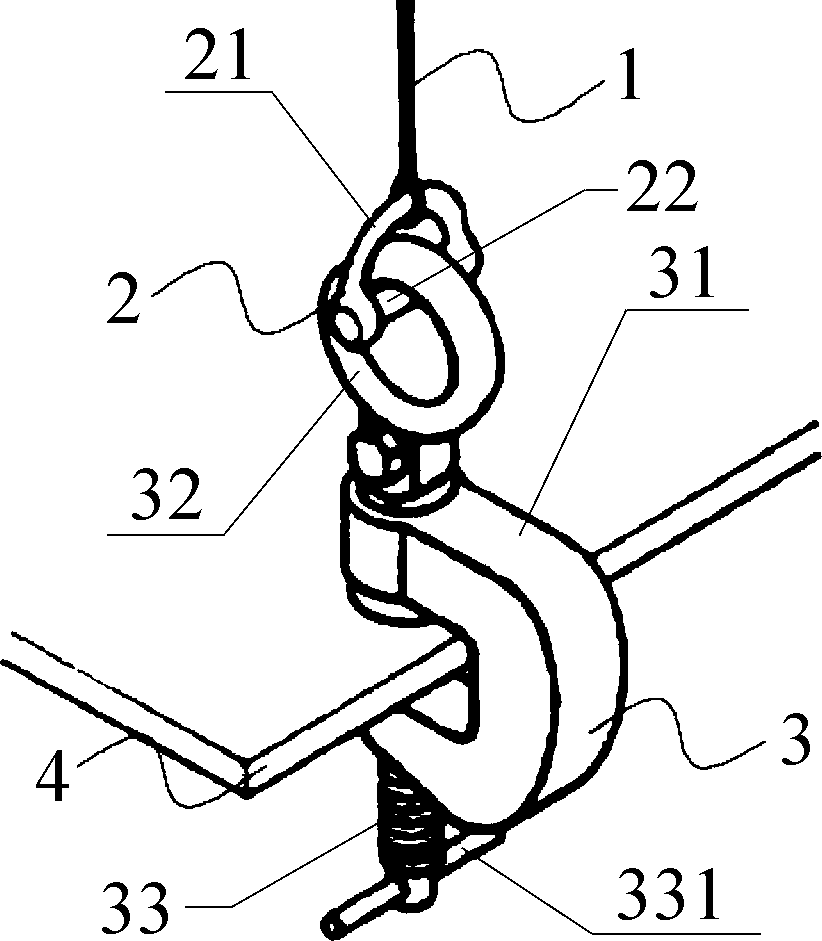

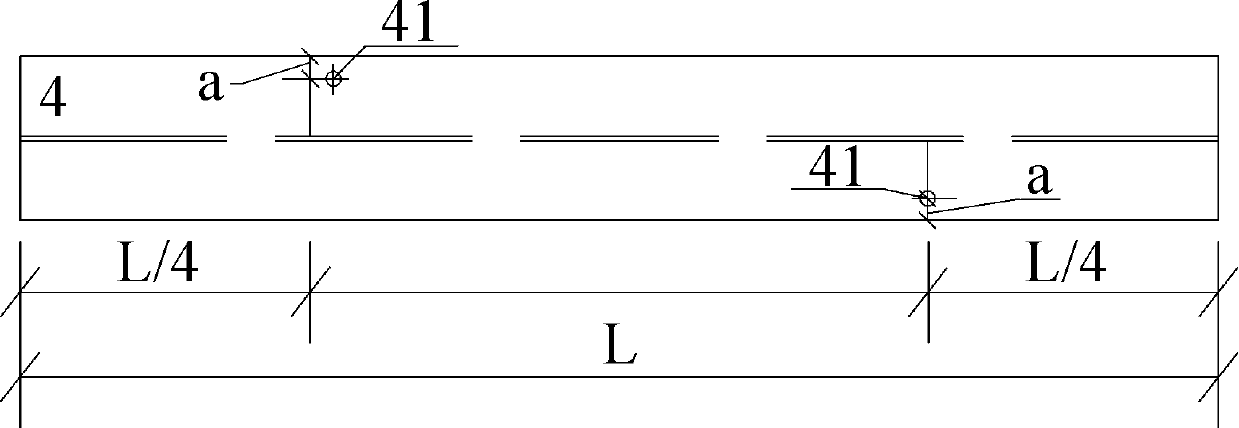

[0023] A structural node for hoisting H-shaped steel beams, including a wire rope 1, a shackle ring 2 and a bolt locking clamp 3, such as figure 1 As shown, the specific structure is:

[0024] The bolt locking clamp 3 includes a caliper 31, a suspension ring 32 and a fastening bolt 33. The caliper 31 is in the shape of a "匚", the suspension ring 32 is fixed on the outer surface of the upper clamp arm of the caliper 31, and the lower clamp arm of the caliper 31 is provided with a positioning pin. Hole, the outer end of fastening bolt 33 screw rods penetrates from the positioning hole of the lower clamp arm of caliper 31 and faces the inner surface of the upper clamp arm of caliper 31;

[0025] The shackle ring 2 and the suspension ring 32 are entangled with each other, and one end of the wire rope 1 is tied on the shackle ring 2 .

[0026] In this embodiment: the shackle ring 2 is composed of a shackle caliper 21 and a shackle pin 22, the shackle caliper 21 is in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com