Rotary powder spraying and wax injection machine

A rotary and powder spraying technology, which is applied to casting and molding equipment, etc., can solve the problems that affect the qualified rate of wax mold molding, the amount of powder spraying cannot be controlled, and the powder spraying is uneven, so as to achieve simple structure, cost saving, and improvement The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

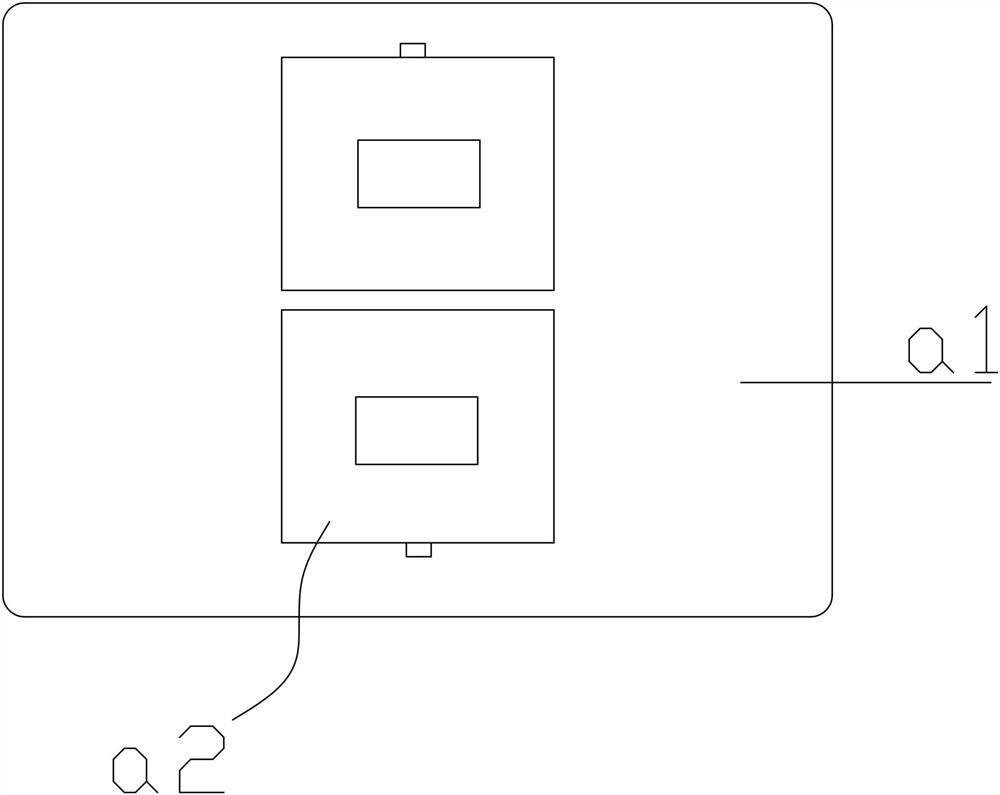

[0024] Such as Figure 1 to Figure 8 As shown, a rotary powder spraying and wax injection complete machine described in this embodiment includes a double-station workbench a1, and two symmetrically arranged powder spray and wax injection integral structures a2 are arranged on the double-station workbench .

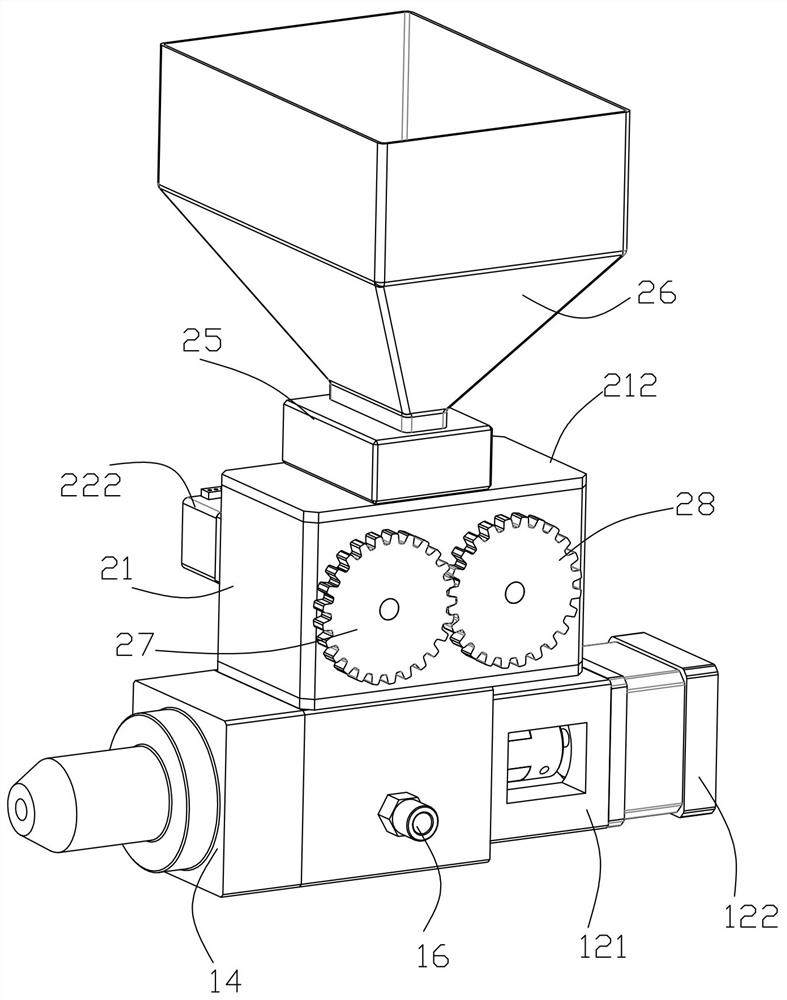

[0025] The integrated structure of powder spraying and wax injection includes quantitative feeding components and rotary feeding nozzle components;

[0026] The rotary feeding nozzle assembly includes a feeding seat 11, a first driving device, a rotating feeding shaft 13 and a feeding nozzle 14, and the first driving device is fixed on one side of the feeding seat 11, and the feeding nozzle 14 is fixed on the opposite side of the feed seat 11, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com