Method for simultaneously producing lithium ion battery pole pieces of multiple models and extrusion coating device

A lithium-ion battery, battery pole piece technology, applied in the direction of electrode extrusion, battery electrode, electrode current collector coating, etc., can solve problems such as poor production flexibility, improve production flexibility, improve production flexibility, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

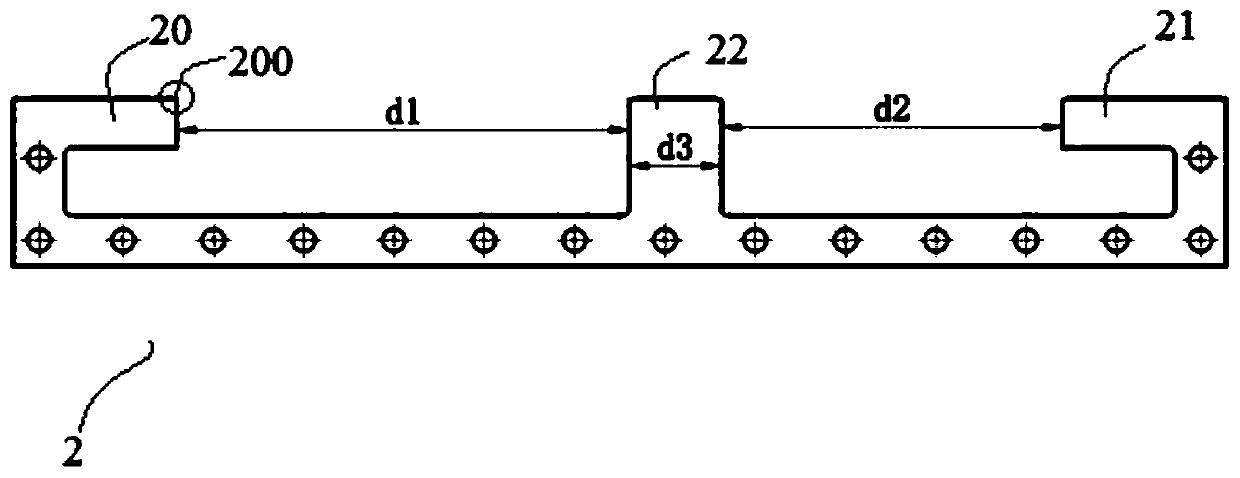

[0038] Table 1 shows the dimensions of the die shims involved in the methods of Embodiment 1 and Embodiment 2 and the die shims of the comparative example.

[0039] Die gasket size involved in table 1 embodiment and comparative example

[0040] Numbering

d1 / mm

d2 / mm

d3 / mm

comparative example

367.5

367.5

57.5

Example 1

367.5

283.5

56.5

Example 2

367.5

343.5

49.5

[0041] The design parameters of battery type 1, battery type 2, and battery type 3 are shown in Table 2.

[0042] Table 2 Design parameters of different battery models

[0043]

[0044] Table 3 shows the measured coating void size data of the comparative examples and examples.

[0045] Table 3 Comparative Example and the actual measurement coating void size data of embodiment

[0046]

[0047]

[0048] Use a steel ruler with an accuracy of 0.5mm to measure the coating area and blank size of the coated pole piece; use a Ф25mm circular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com