Tool, and test apparatus and method

A jig and display technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of inability to test the lighting of the display, and the fixture of the lighting of the display is not universal, so as to achieve universality and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

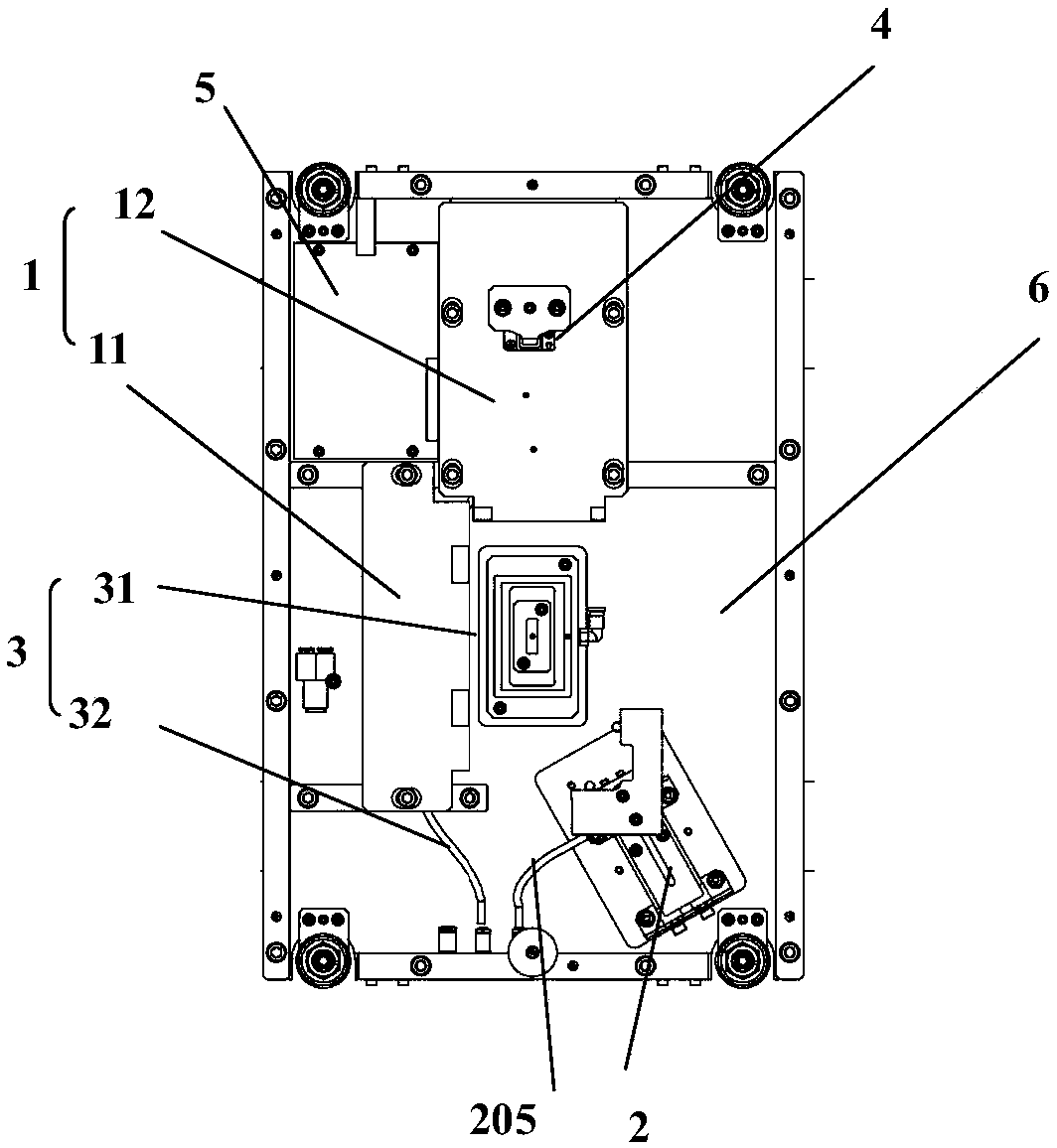

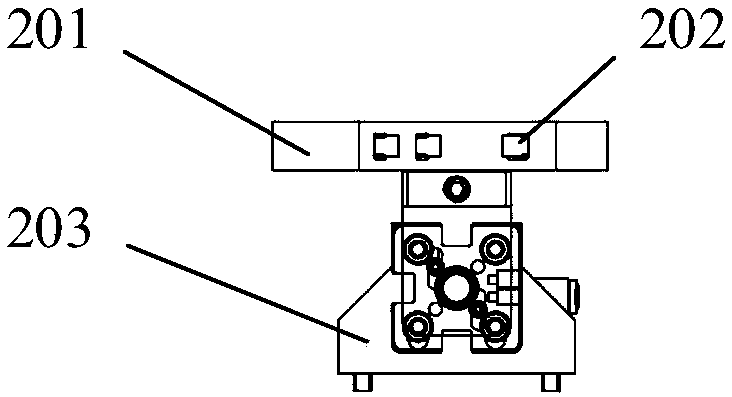

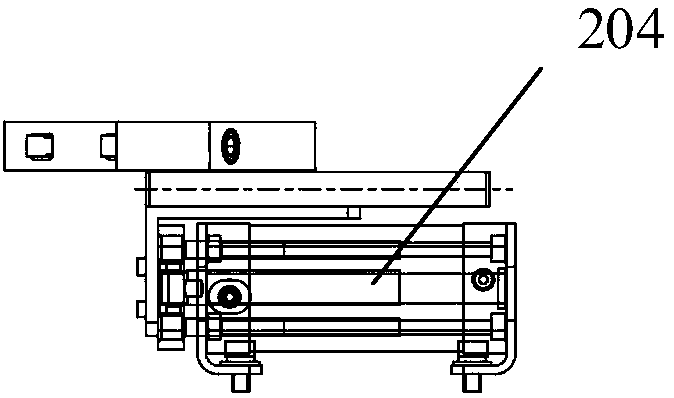

[0048] refer to figure 1 , which is a schematic diagram of the fixture provided in the embodiment, such as figure 1As shown, the jig includes a base 6 and a positioning reference unit 1, a clamping unit 2, an adsorption unit 3, a crimping unit 4 and a lighting signal board 5 arranged on the base 6; the clamping unit 2 and the The positioning reference unit 1 moves relatively and makes the display screen clamped between the clamping unit 2 and the positioning reference unit 1; the adsorption unit 3 is used to absorb the display screen; the crimping unit 4 Realize the signal connection between the lighting signal board 5 and the FPC interface of the display screen. The jig provided by the present invention can clamp the display screen between the positioning reference unit 1 and the clamping unit through the relative movement of the clamping unit 2 and the positioning reference unit 1, because the clamping unit 2 can It moves on the base, so it can clamp display screens of dif...

Embodiment 2

[0059] Such as Figure 8 As shown, in this embodiment, the jig includes a base and a positioning reference unit, a clamping unit, an adsorption unit 3, a crimping unit 4 and a lighting signal board arranged on the base; the clamping unit can be placed on the Move on the base and make the display screen be clamped between the clamping unit and the positioning reference unit; the adsorption unit 3 is used to absorb the display screen; the crimping unit 4 realizes the lighting The signal board is connected to the signal of the FPC interface of the display screen. The difference between this embodiment and Embodiment 1 is that both the positioning reference unit and the clamping unit can move axially, and the stroke of the positioning reference mechanism is locked according to the position and size of the display screen. Within the stroke range, the drive positioning reference unit and the clamping unit move synchronously and oppositely to push the display screen, specifically as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com