Rear axle efficiency test method based on NEDC (New European Driving Cycle) oil consumption working conditions

An efficiency test and rear axle technology, applied in the transmission field, can solve the problems of too many working points and too large deviation between the simulation results and the measured results, and achieve the effect of predicting the impact and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The present invention provides a kind of rear axle efficiency testing method based on NEDC fuel consumption operating condition, and described method comprises the following steps:

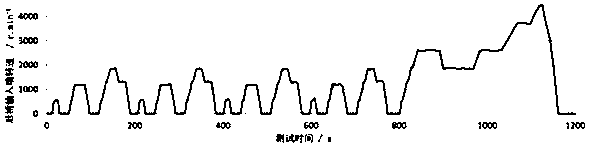

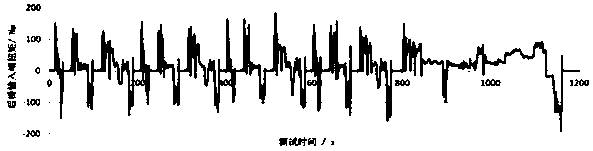

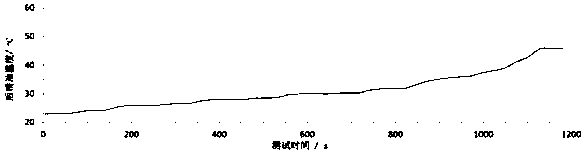

[0029] Step S1: read the speed data, torque data and the oil temperature data of the rear axle in the NEDC fuel consumption condition test or the simulation result of the input end;

[0030] Preferably, the sampling frequency of the input speed, torque and oil temperature data of the rear axle in the step S1 should be the same. The frequency of data sampling in the step S1 does not exceed 10 Hz.

[0031] The most important point of a test method is the validity of the test data. In this test method, the sampling of the input speed, torque and oil temperature da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com