Automatic-leveling base system and using method thereof

A base, automatic technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of cumbersome work and affect the construction quality of pipe jacking construction, and achieve the effect of simplifying the work process, improving the construction quality and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

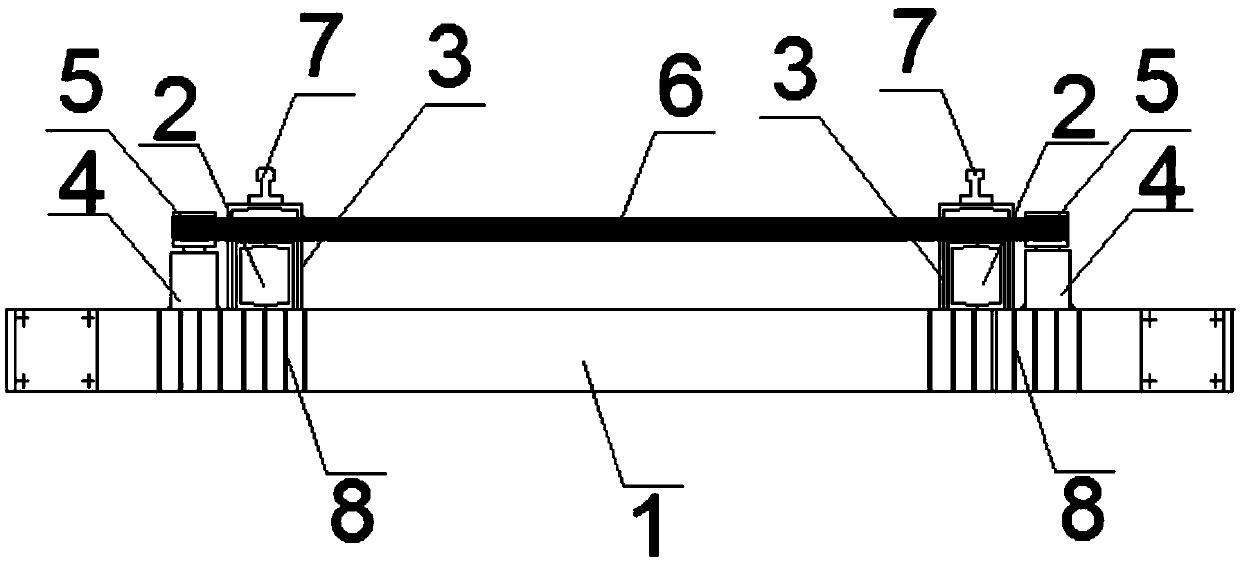

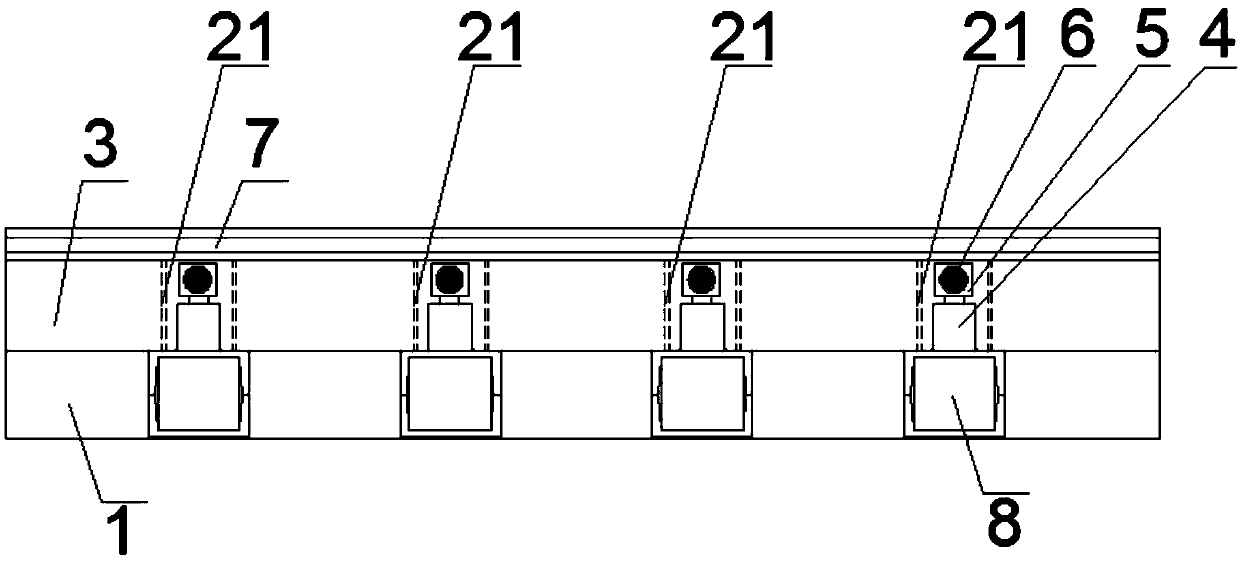

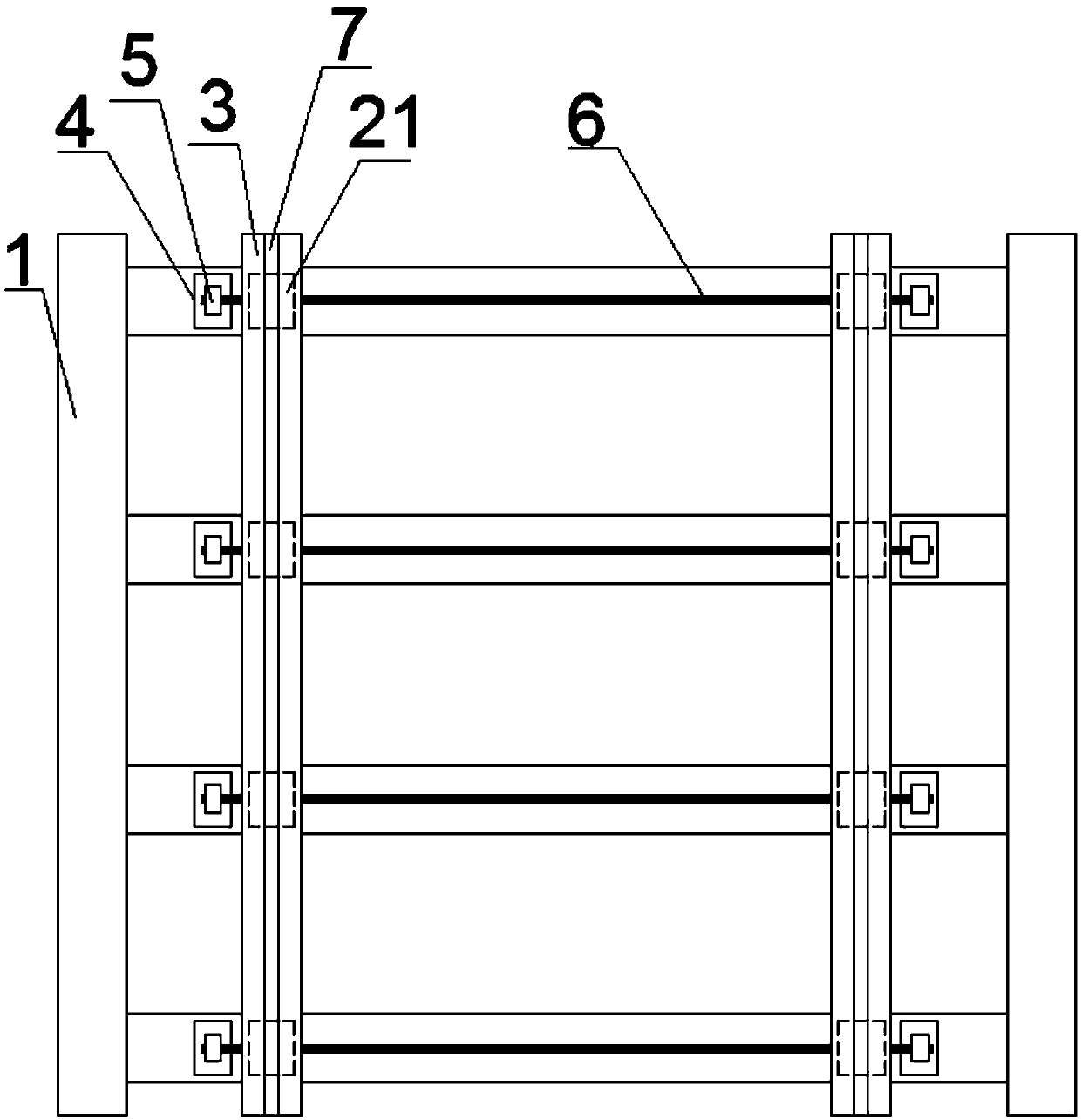

[0039] refer to Figure 1 to Figure 3 , the present embodiment provides an automatic leveling base system, including a base 1, two sets of socket rails 2, two guide frames 3 with pipe section guide rails 7 on the upper parts, several jacks 4 with lug plates 5 on the upper parts, and several lift bar 6;

[0040] Two sets of socket rails 2 are arranged in parallel on the base 1;

[0041] The two guide frames 3 are sleeved on the socket track 2 respectively;

[0042] Several lifting rods 6 are arranged in parallel between the two guide frames 3, and each lifting rod 6 respectively passes through the two guide frames 3 to connect the two guide frames 3 together;

[0043] Both ends of the lifting rod 6 extend to the outside of the guide frame 3 and are respectively connected to the jack 4 arranged on the base 1 outside the guide frame 3 through the lug plates 5 .

[0044] In the automatic leveling base system of this embodiment, a lifting rod 6 is provided between the guide fram...

Embodiment 2

[0056] refer to Figure 1 to Figure 3 , this embodiment provides a method for using the self-leveling base system described in Embodiment 1.

[0057] The technical solution of a method for using an automatic leveling base system in this embodiment is as follows, including the following steps:

[0058] The first step is to install the self-leveling base system in the foundation pit of the working well;

[0059] In the second step, the pipe joint is placed on the guide rail 7;

[0060] The third step is to carry out pipe jacking construction on the pipe joints. During the construction process, the control system adjusts the lifting height of each jack 4 so that the elevation of the pipe jacking construction is within the set range;

[0061] In the fourth step, after the pipe jacking construction is completed, each jack 4 is lowered to separate the pipe section guide rail 7 from the end of the pipe section;

[0062] The fifth step is to remove the self-leveling base system.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com