Automatic cooker

A cooking machine and gas technology, which is applied in the field of cooking machines, can solve the problem of difficult to reflect the progress of time cooking, and achieve the effect of ensuring the taste and flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

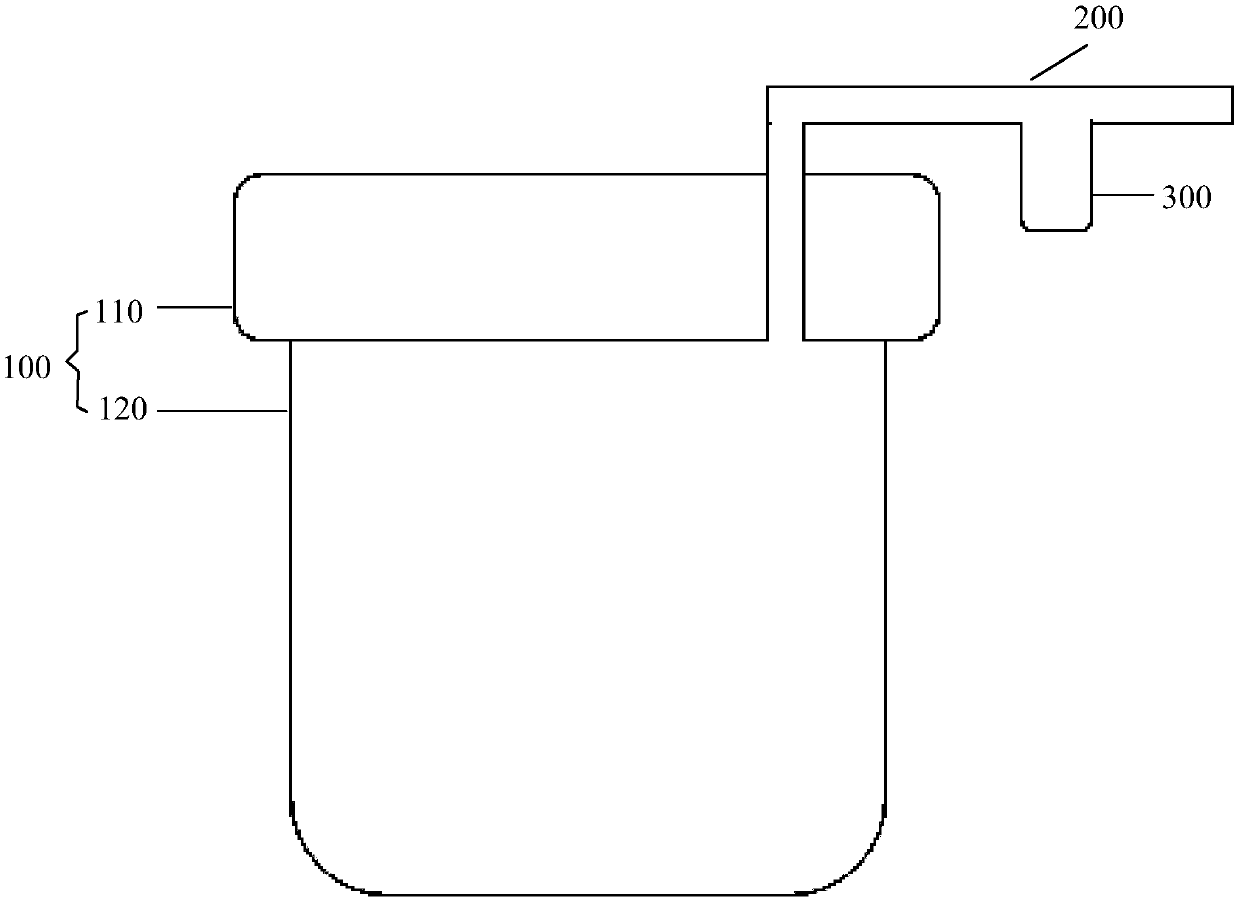

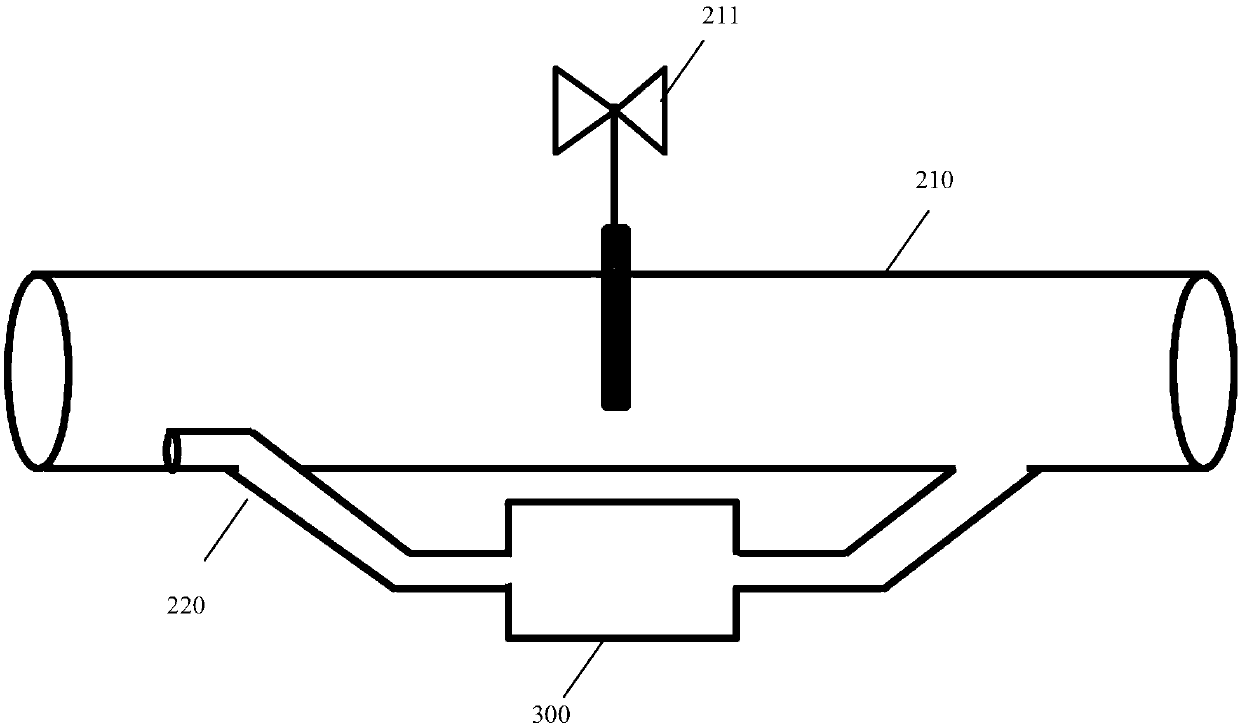

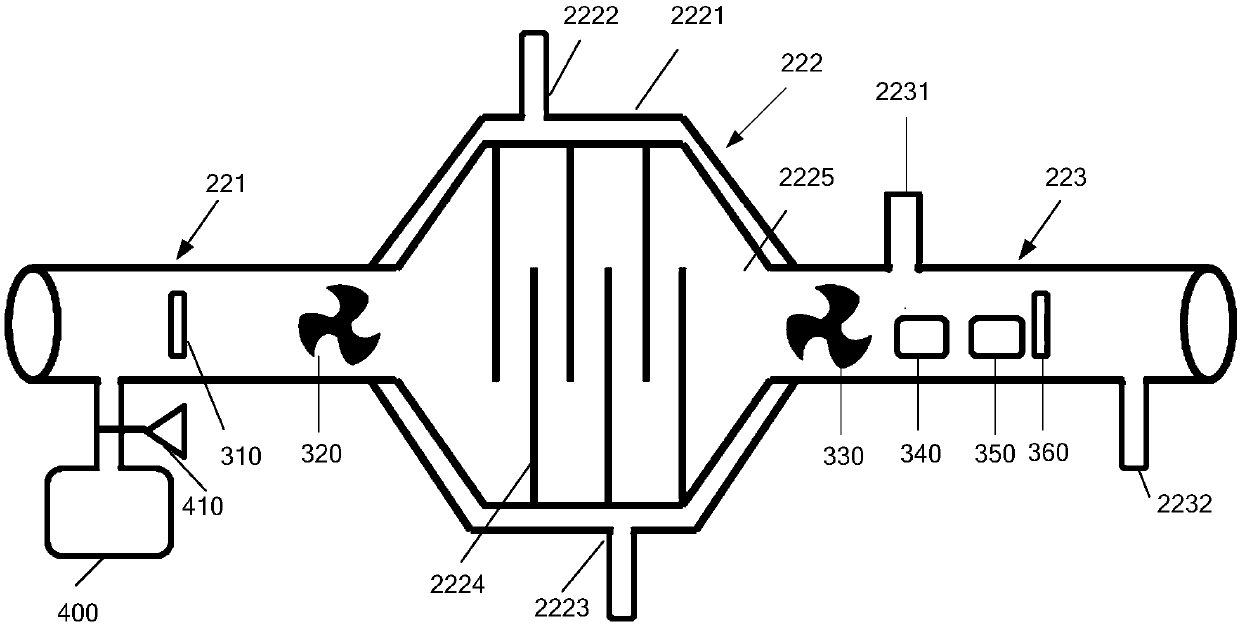

[0022] Such as figure 1 As shown, in the first embodiment of a cooking machine of the present invention, it includes a cooking machine control unit and a pot 100, and also includes a gas that is connected to the pot 100 and is used to obtain the sampling gas from the pot 100. The sampling unit 200, and the electronic olfactory detection unit 300 arranged in the gas sampling unit 200 and connected to the cooking machine control unit for monitoring the gas parameters of the sampled gas. Specifically, a gas sampling unit 200 that cooperates with the pot 100 is set inside the cooking machine to collect the food gas in the pot 100 during the cooking process to obtain sampled gas. The electronic smell detection unit 300 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com