Small vertical shaft type deep cultivator

A vertical shaft type, deep tiller technology, applied in the fields of tillage equipment, agricultural machinery and equipment, application, etc., can solve the problems of reduced soil aeration, reduced aerobic microorganisms, inability to adapt to hilly and mountainous terrain conditions, etc., and achieves operating power consumption. Reduce and improve the effect of soil water storage and moisture retention, good machine stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the example of patent of the present invention is described in detail.

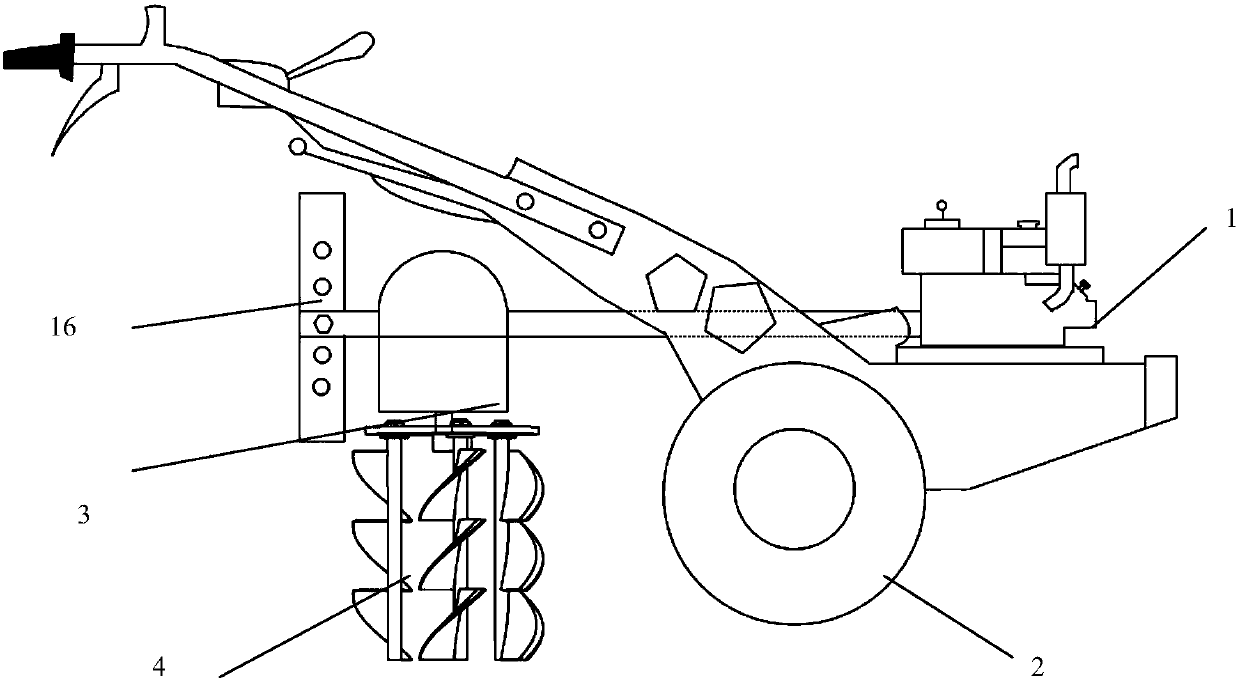

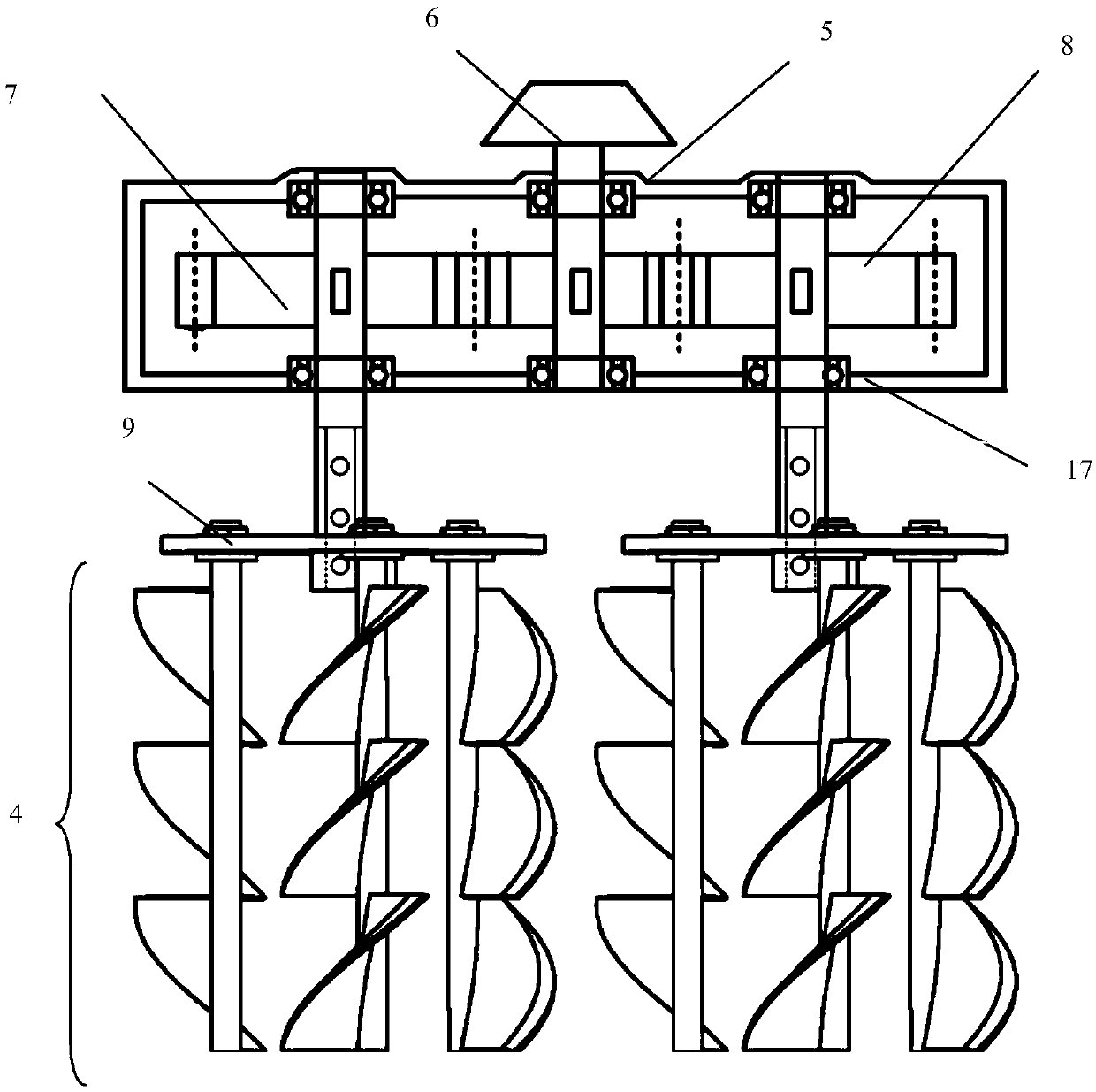

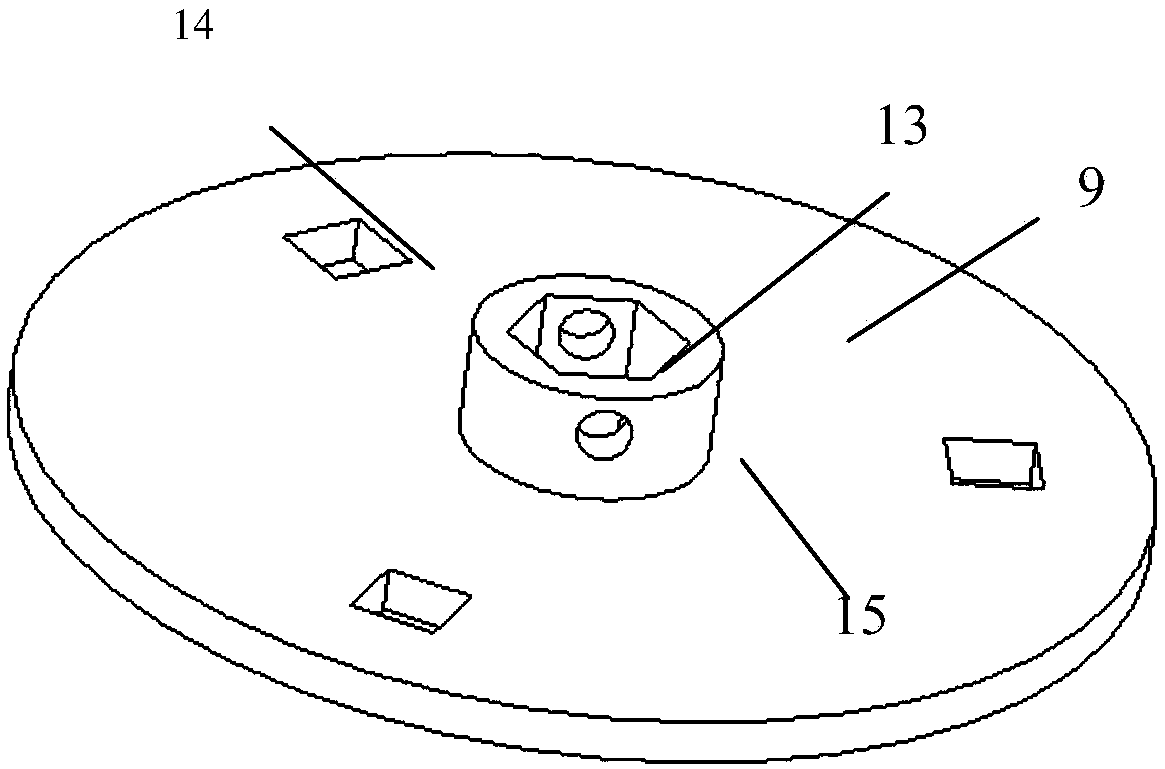

[0014] As shown in the accompanying drawings, the present invention is a small vertical shaft deep cultivator. It mainly includes a power unit 1, a traveling wheel 2, a transmission box 3, and a segmented discontinuous spiral cutter 4. The transmission shaft 5 is installed in the transmission case through two bearings 17 at the central axis position of the transmission case 3 to ensure that the installation positions of the two tool shafts 8 spur gears are symmetrical about the axis of the transmission shaft 5 and are installed in the transmission case through the bearings. The three vertical-shaft segmented discontinuous helical cutters 4 have the same external dimensions, the same rotational speed and direction of rotation, and are vertically arranged with the forward direction of the deep cultivator. The two segmented non-continuous helical cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com