Method for operating a waste heat steam generator

A technology of waste heat steam and generator, applied in steam generation, feed water heater, preheating, etc., to achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

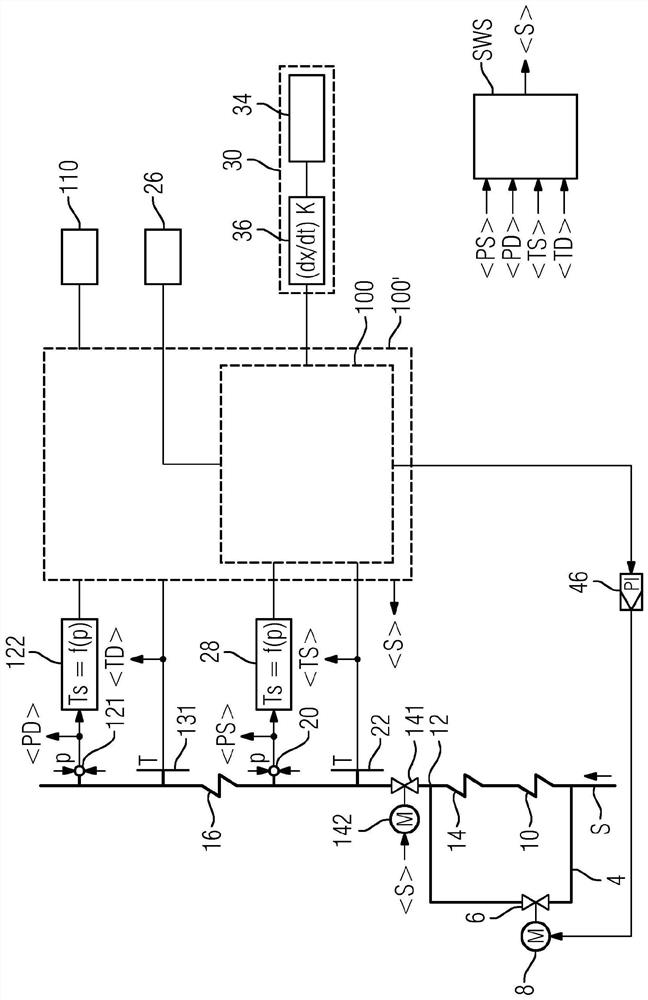

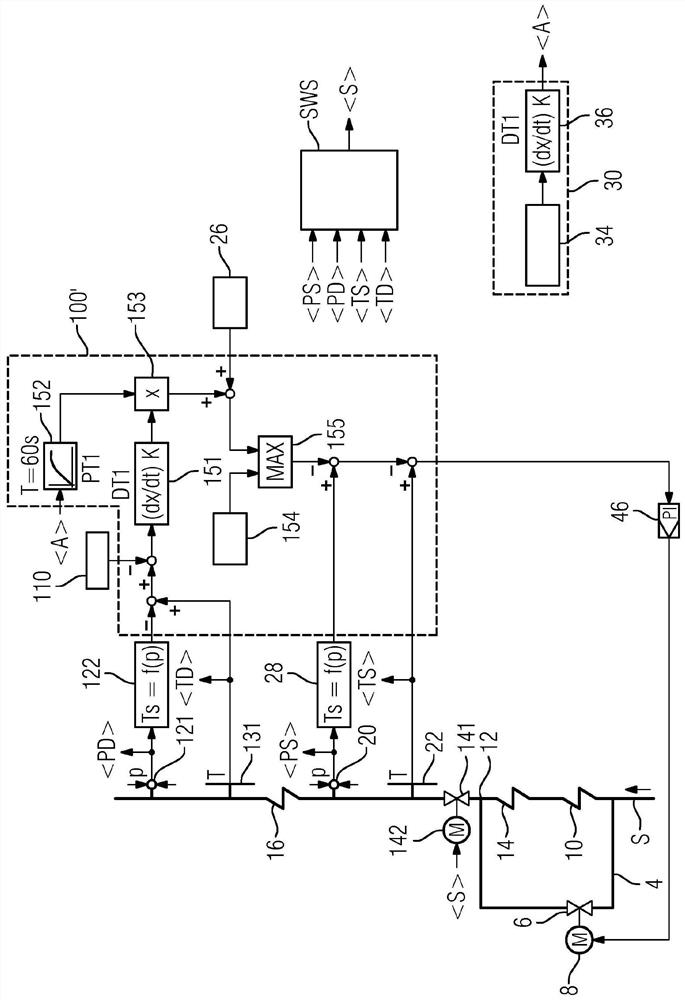

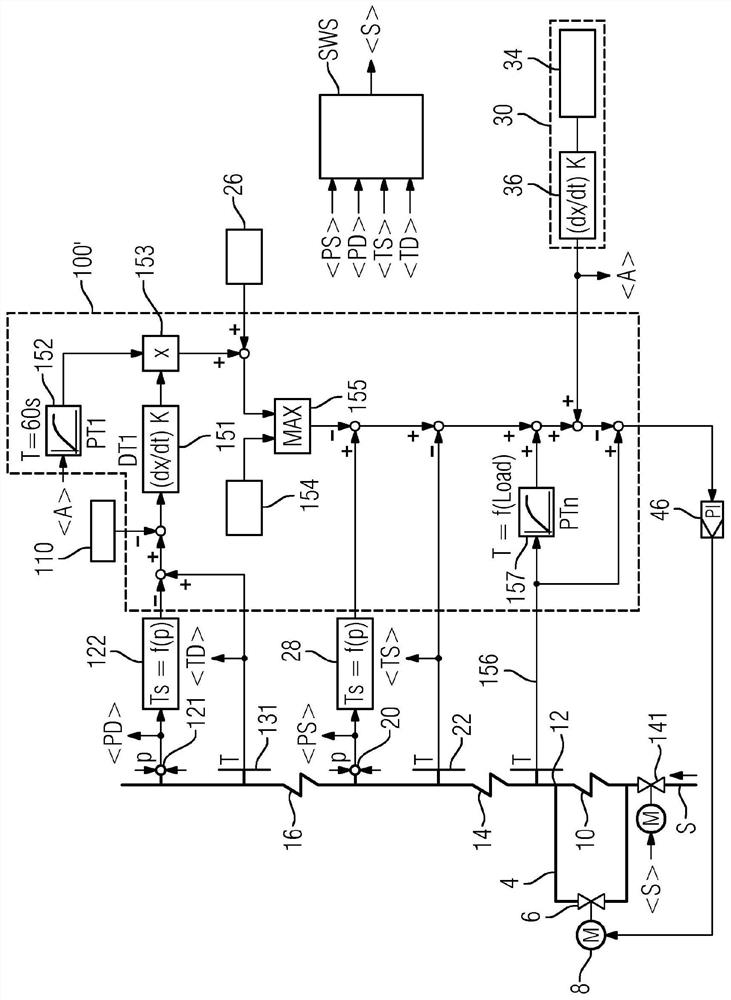

[0012] figure 1 First, a first configuration of the waste heat steam generator that can be adjusted is schematically shown. The flow medium S driven by a pump (not specifically shown) first flows into the first preheater heating surface or economizer heating surface 10 . However, the bypass line 4 has previously branched. In order to regulate the flow rate of the bypass line 4 a flow control valve 6 adjustable by a controllable motor 8 is provided. Simple control valves can also be provided, however, the subcooling at the evaporator inlet can be better regulated by means of fast-acting control valves. Thus, depending on the position of the flow control valve 6 , part of the flow medium S flows into the bypass line 4 , another part of the flow medium S flows through the first economizer heating surface 10 and then through the other economizer heating surface 14 . In the present design, at the outlet of the economizer heated surface 14 , the flow medium from the bypass line 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com