Color film substrate and manufacturing method thereof

A color filter substrate and mask technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as poor peripheral display, and achieve the effect of solving poor peripheral display, reducing production process steps, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

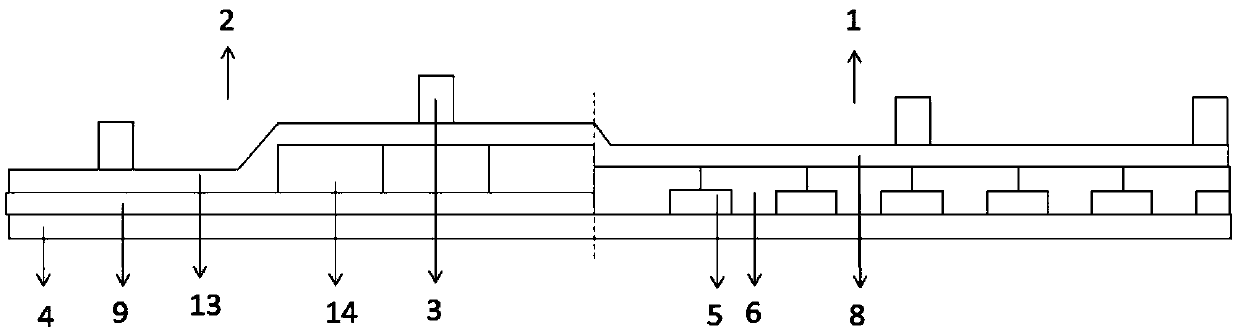

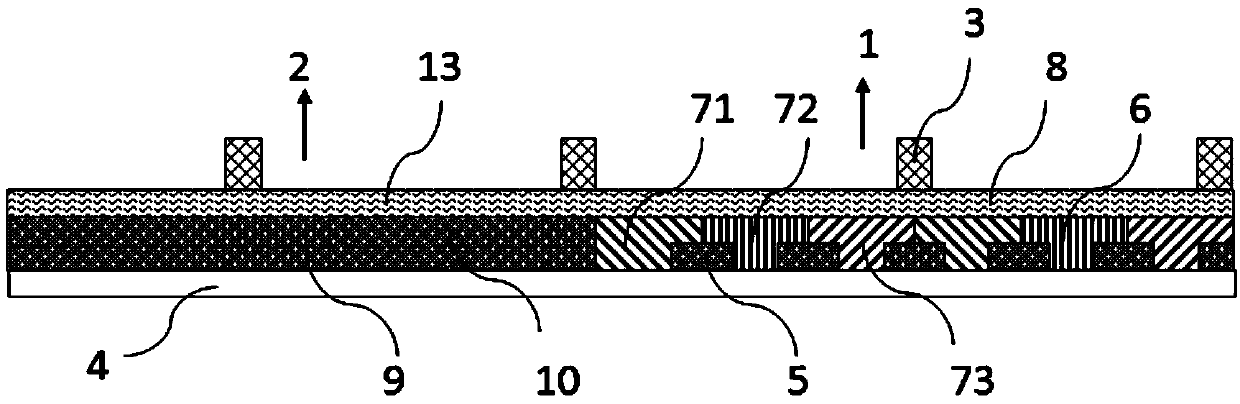

[0046] figure 2It is a structural schematic diagram of the first embodiment of the present invention, a color filter substrate, including: a display area 1 and a non-display area 2 located around the display area 1, the display area 1 includes a plurality of first black matrices 5 arranged in matrix, A plurality of pixel areas defined by the first black matrix 5, a color-resist layer 6 located in each pixel area, and a first planarization layer 8 covering the color-resist layer 6, the color-resist layer 6 partially covers the first black matrix5. The non-display area 2 includes a second black light-shielding layer 9 , a pad layer covering the second black light-shielding layer 9 , and a second planarization layer 13 covering the pad layer.

[0047] The color filter substrate further includes a plurality of support pillars 3 disposed on the first planarization layer 8 and the second planarization layer 13 .

[0048] In this embodiment, each pixel area is provided with three ...

Embodiment 2

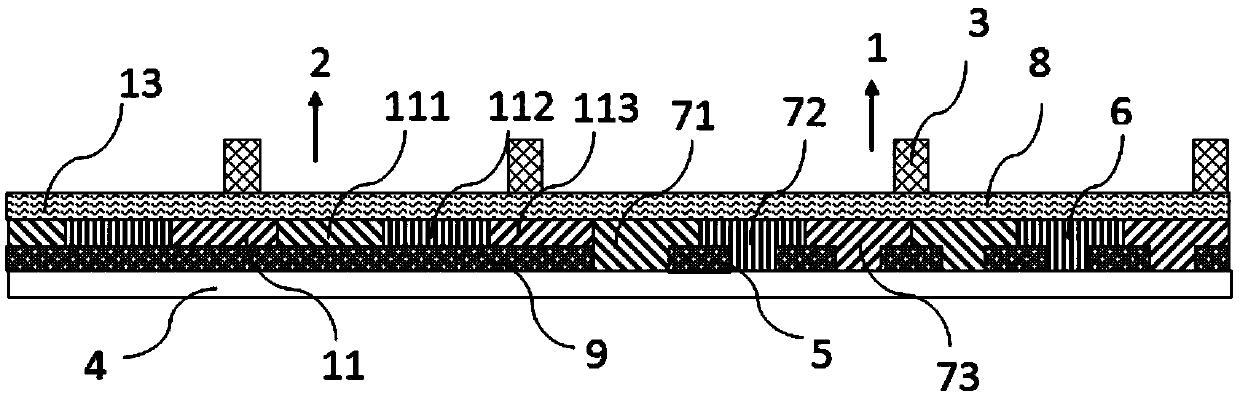

[0054] image 3 It is a structural schematic diagram of the second embodiment of the present invention, a color filter substrate, including: a display area 1 and a non-display area 2 located around the display area 1, the display area 1 includes a plurality of first black matrices 5 arranged in a matrix, A plurality of pixel areas defined by the first black matrix 5, a color-resist layer 6 located in each pixel area, and a first planarization layer 8 covering the color-resist layer 6, the color-resist layer 6 partially covers the first black matrix5. The non-display area 2 includes a second black light-shielding layer 9 , a pad layer covering the second black light-shielding layer 9 , and a second planarization layer 13 covering the pad layer.

[0055] The color filter substrate further includes a plurality of support pillars 3 disposed on the first planarization layer 8 and the second planarization layer 13 .

[0056] In this embodiment, each pixel area is provided with thr...

Embodiment 3

[0065] Figure 4 It is a structural schematic diagram of the third embodiment of the present invention, a color filter substrate, including: a display area 1 and a non-display area 2 located around the display area 1, and the display area 1 includes a plurality of first black matrices 5 arranged in a matrix, A plurality of pixel areas defined by the first black matrix 5, a color-resist layer 6 located in each pixel area, and a first planarization layer 8 covering the color-resist layer 6, the color-resist layer 6 partially covers the first black matrix5. The non-display area 2 includes a second black light-shielding layer 9 , a pad layer covering the second black light-shielding layer 9 , and a second planarization layer 13 covering the pad layer.

[0066] The color filter substrate further includes a plurality of support pillars 3 disposed on the first planarization layer 8 and the second planarization layer 13 .

[0067] The pad layer is the third planarization layer 12 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com