Rotary household garbage low-temperature pyrolyzing furnace

A technology of low-temperature pyrolysis and domestic waste, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as difficult quality control, difficult site selection, limited scale, etc., and achieve the effect of adjustable waste layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

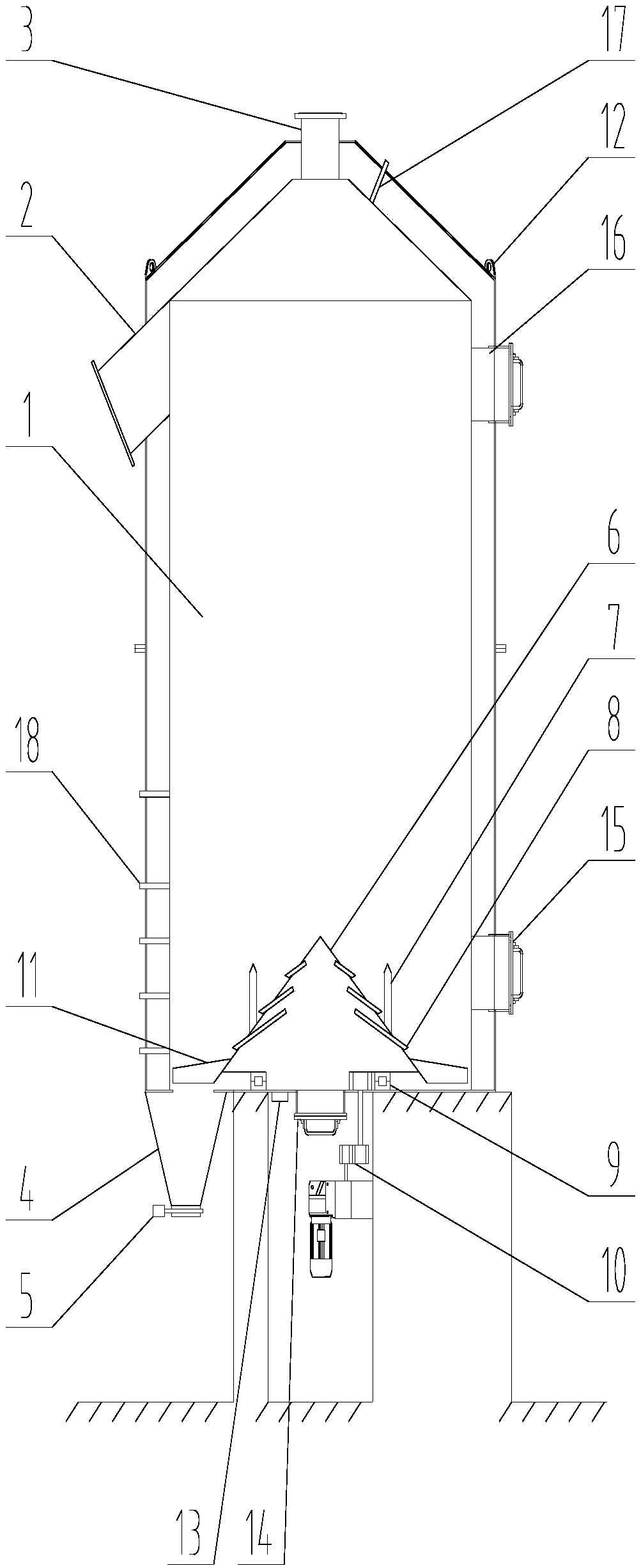

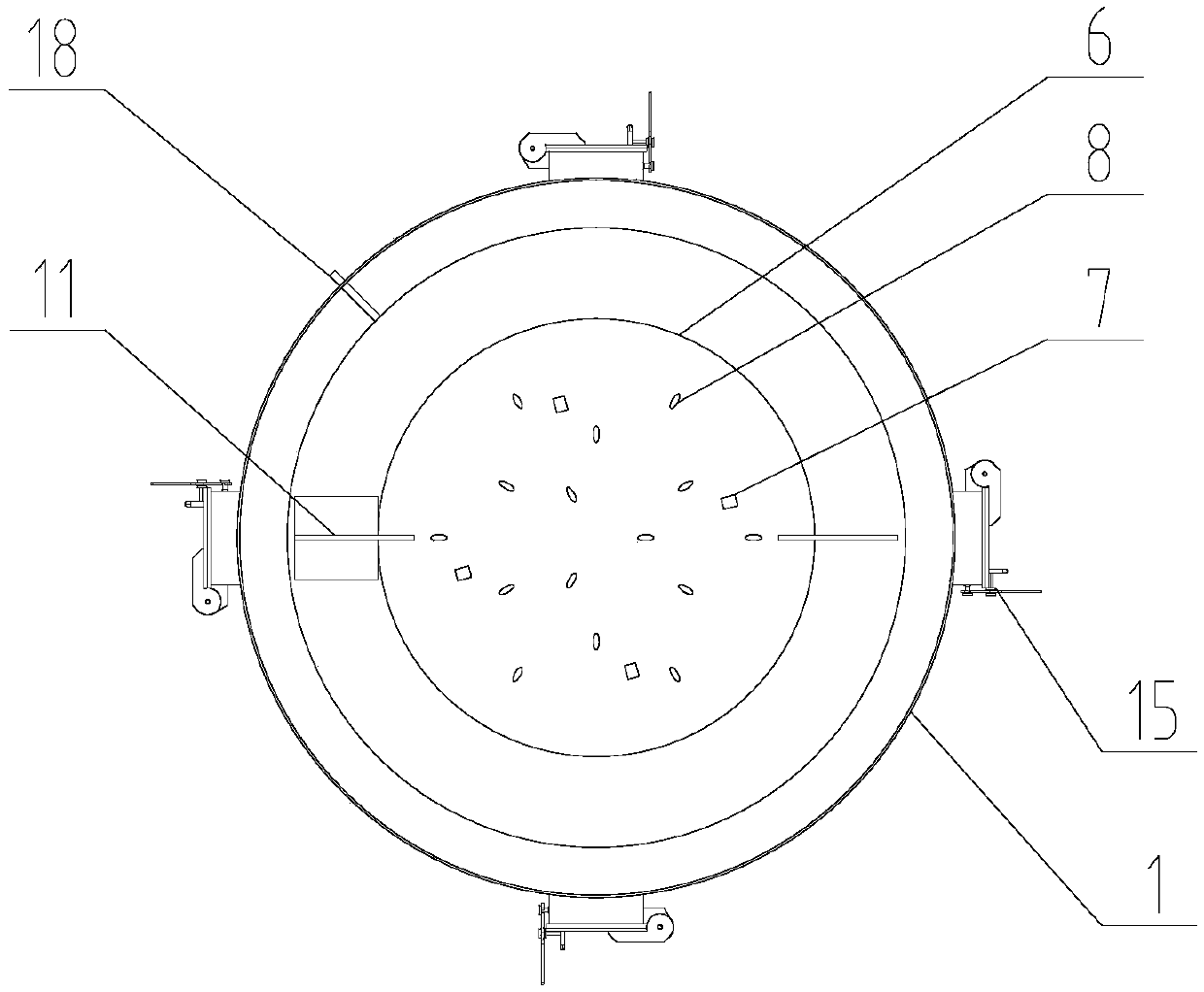

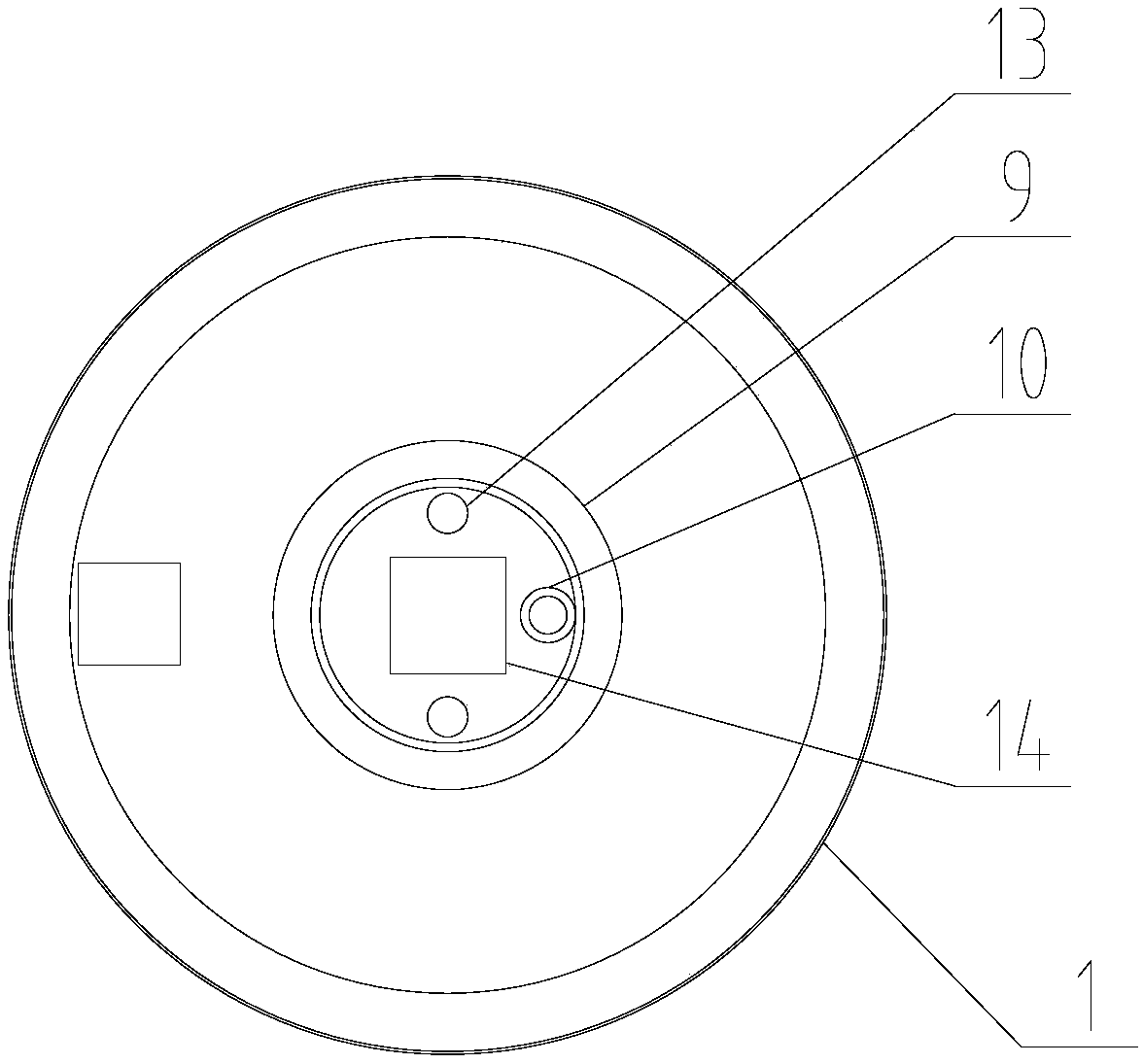

[0025] Such as Figure 1 to Figure 3 As shown, the rotatable domestic waste low-temperature pyrolysis furnace of the present invention includes a pyrolysis furnace body 1, a garbage inlet 2, a flue gas outlet 3, an ash hopper 4, an automatic ash-removing flat valve 5, and a pyrolysis cone 6. Stirring device 7, air distribution device 8, bearing turntable 9, driving device 10, dust scraping plate 11, lifting lug 12, air valve 13, bottom inspection port 14, lower inspection port 15, upper observation port 16, outlet thermometer 17 And furnace body thermometer 18. The specific structure and connection relationship are:

[0026] The outside of the pyrolysis furnace body 1 is provided with a high-temperature-resistant steel plate, and the bottom plate of the pyrolysis furnace body 1 is provided with an ash discharge port. The pyrolysis furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com