A sterilizing bacteriostatic laundry detergent and a preparing process thereof

A technology of laundry detergent and ethanol aqueous solution, which is applied in the direction of detergent composition, soap detergent composition, surface active detergent composition, etc., can solve the problem of reducing the sterilization and antibacterial effect of laundry detergent, the decontamination ability discount of laundry detergent, Poor bactericidal and antibacterial ability, etc., to achieve reduced volatilization, good antibacterial effect, and excellent antibacterial and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: A bactericidal and antibacterial laundry detergent, the components included and their corresponding qualities are shown in Table 1, and are prepared through the following steps:

[0052] Step 1, fully mixing the anti-association component, ethanol aqueous solution, p-chloro-m-xylenol, and deionized water to obtain the first mixture;

[0053]Step 2, fully mixing strong surfactant, PEG-40 hydrogenated castor oil, calcium magnesium chelating agent, sodium chloride, tea tree essential oil with the first mixture obtained in step 1 to obtain the second mixture;

[0054] Step 3: Cool down the second mixture obtained in Step 2 to 40° C., add essence, and mix thoroughly to obtain a bactericidal and antibacterial laundry detergent.

[0055] Wherein, in the aqueous ethanol solution, the mass percentage of ethanol is 95%; the calcium and magnesium chelating agent is EDTA2 sodium; the anti-association component is composed of refined castor oil and potassium hydroxide wit...

Embodiment 2-5

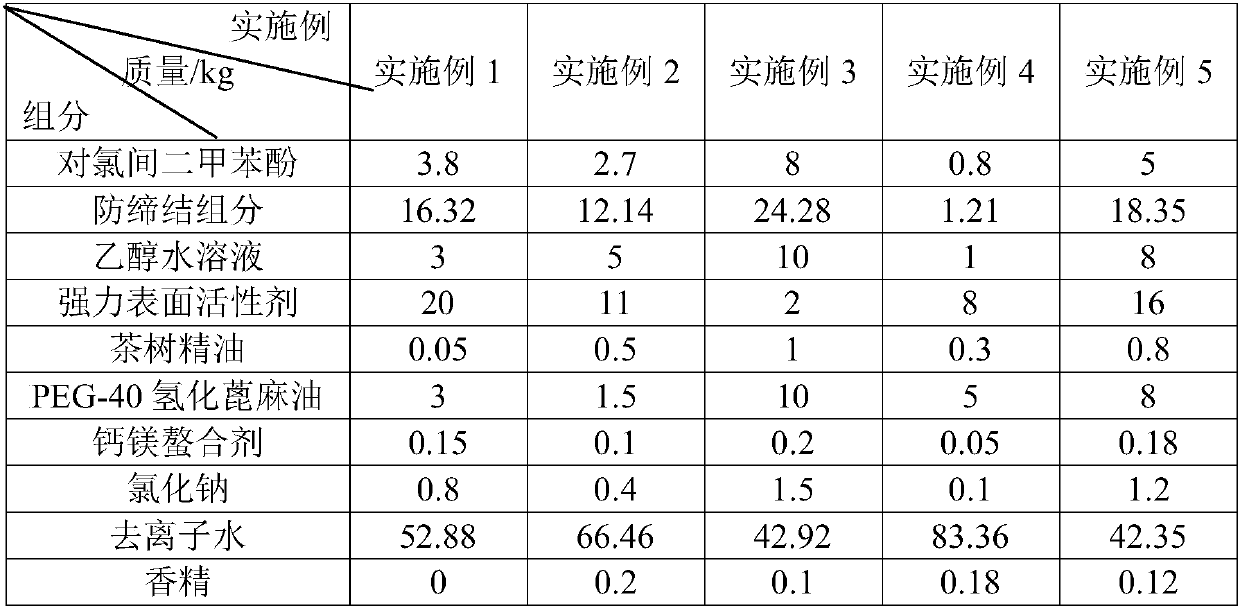

[0056] Example 2-5: A bactericidal and antibacterial laundry detergent, the difference from Example 1 is that the components included and their corresponding qualities are shown in Table 1.

[0057] Components included in table 1 embodiment 1-5 and their corresponding quality

[0058]

Embodiment 6

[0059] Embodiment 6: A bactericidal and antibacterial laundry detergent, the difference from Embodiment 1 is that the anti-binding component is composed of refined castor oil and potassium hydroxide with a weight and number ratio of 1:0.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com