Automatic prestressed clip combining and ring sleeving device

A technology of prestressed clips and clips, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of workers' joints being greatly affected, production labor intensity, etc., and achieve the effect of accurate position placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

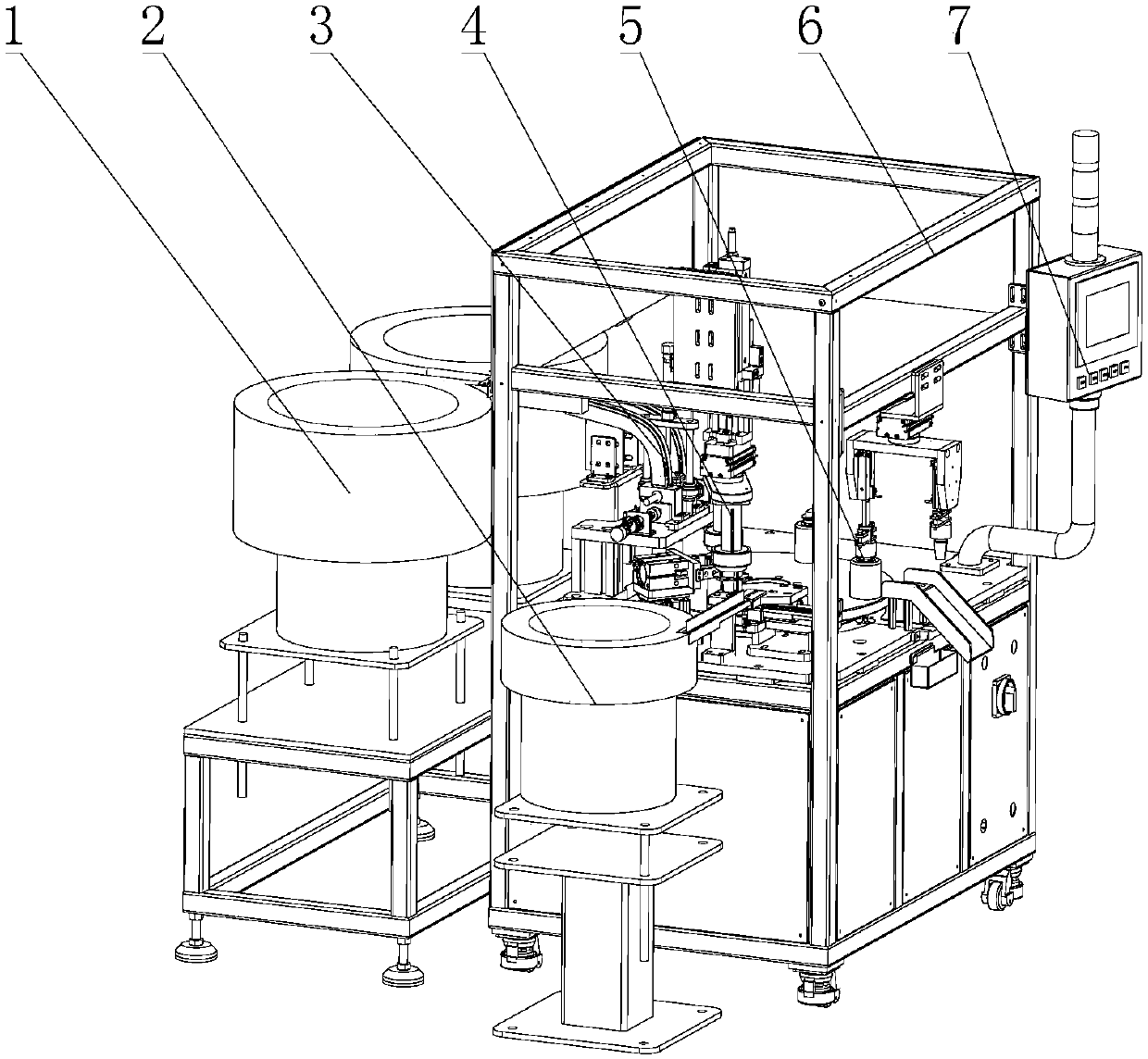

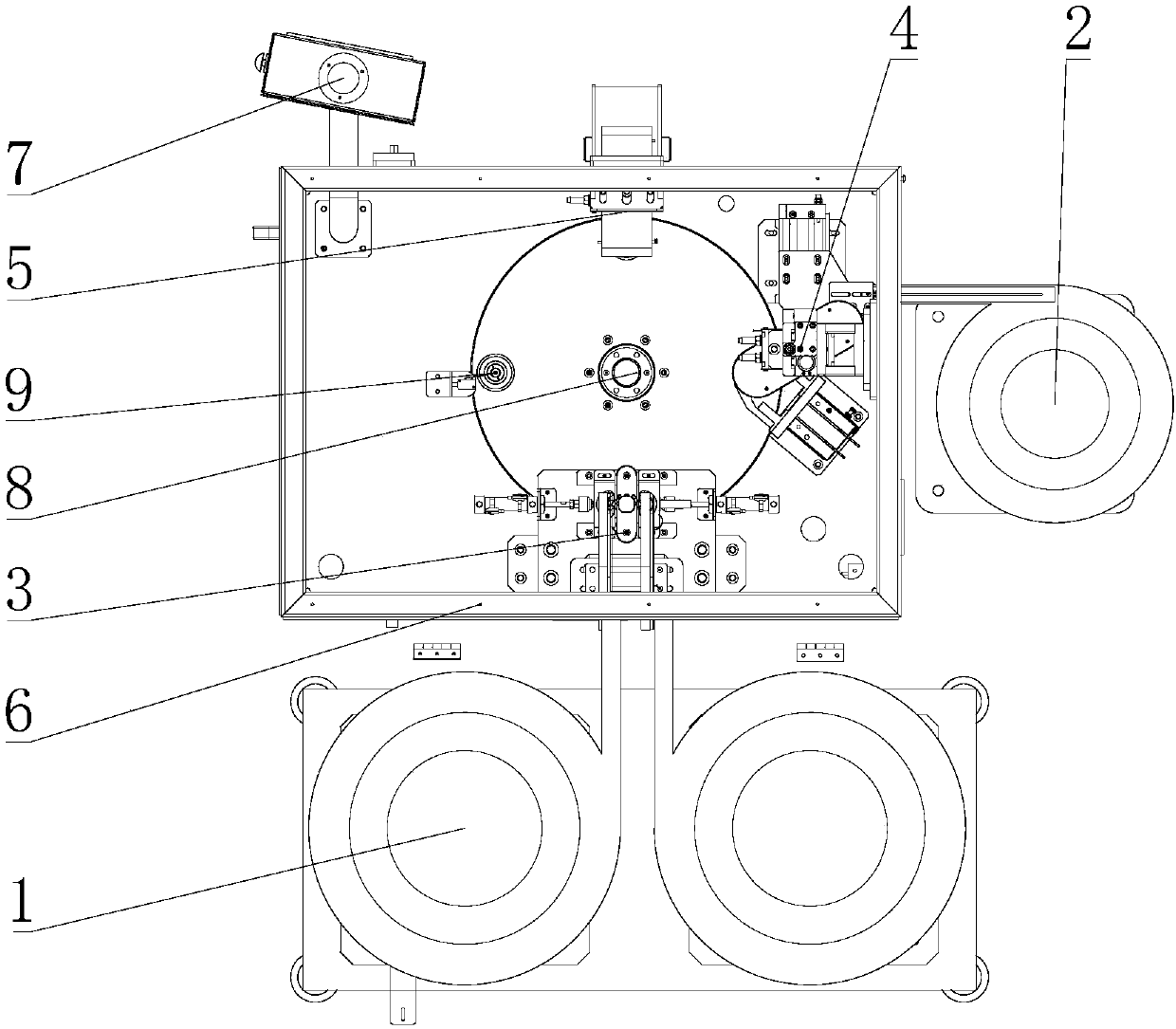

[0027] see Figure 1 to Figure 4 , this embodiment discloses a device for automatically assembling prestressed clips and ferrules, including a clip material sorting and feeding machine 1, an O-ring material sorting and feeding machine 2, a combined station mechanism 3, and a ferrule station Mechanism 4, blanking station mechanism 5, and rotary table 8 are composed.

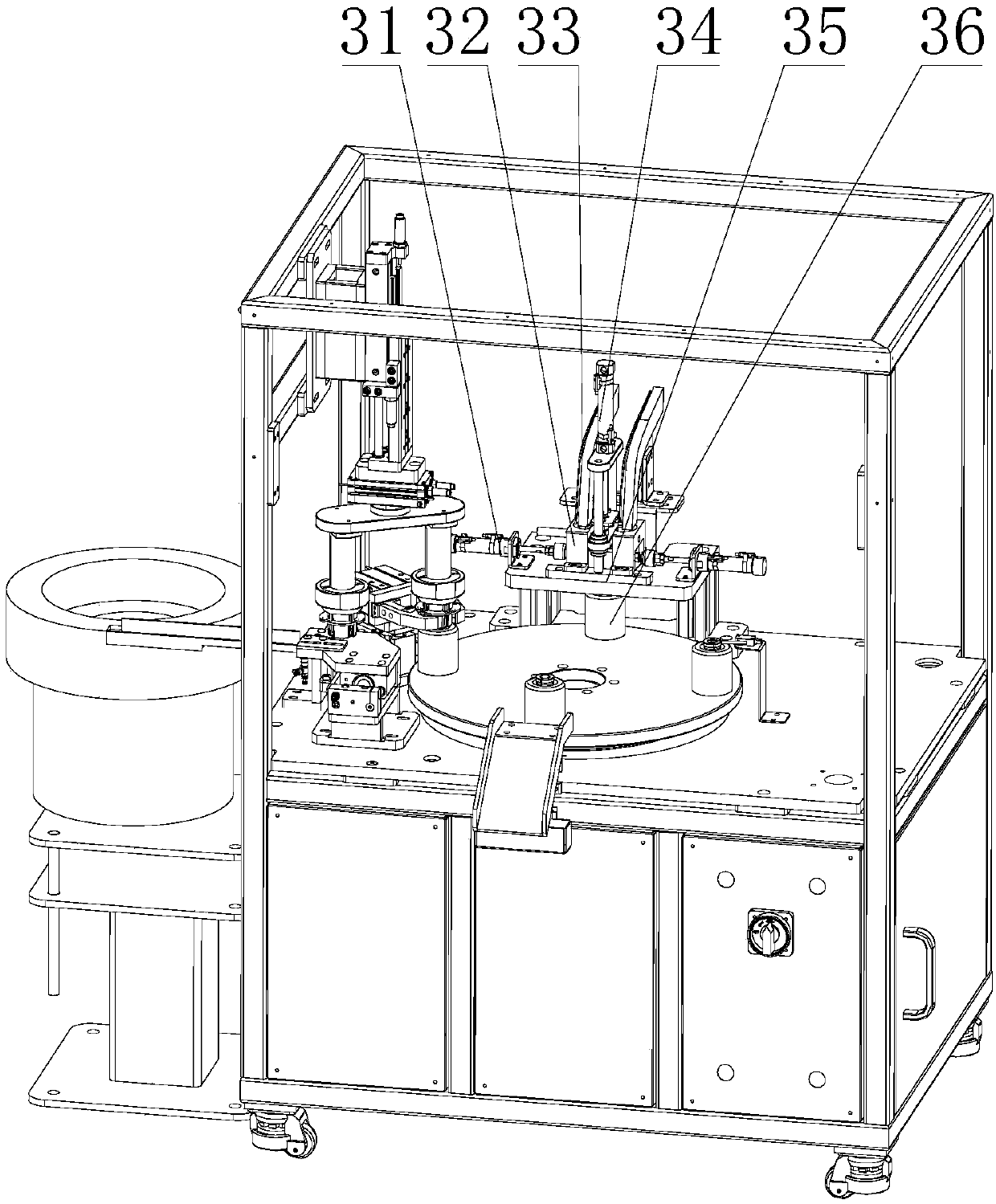

[0028] The assembly station mechanism 3 comprises a left and right side pneumatic push rod 31, a clip buffer cavity 32, a clip blanking slideway 33, a push rod 34 in the middle, a working support plate 35, and a clip tooling mold 36.

[0029] The fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com