Automatic silicon wafer sorting equipment

An automatic sorting and silicon wafer technology, applied in sorting and other directions, can solve problems such as single detection parameters, high false detection rate, and low production efficiency, and achieve the effects of reducing false detection rate, accurate sorting, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

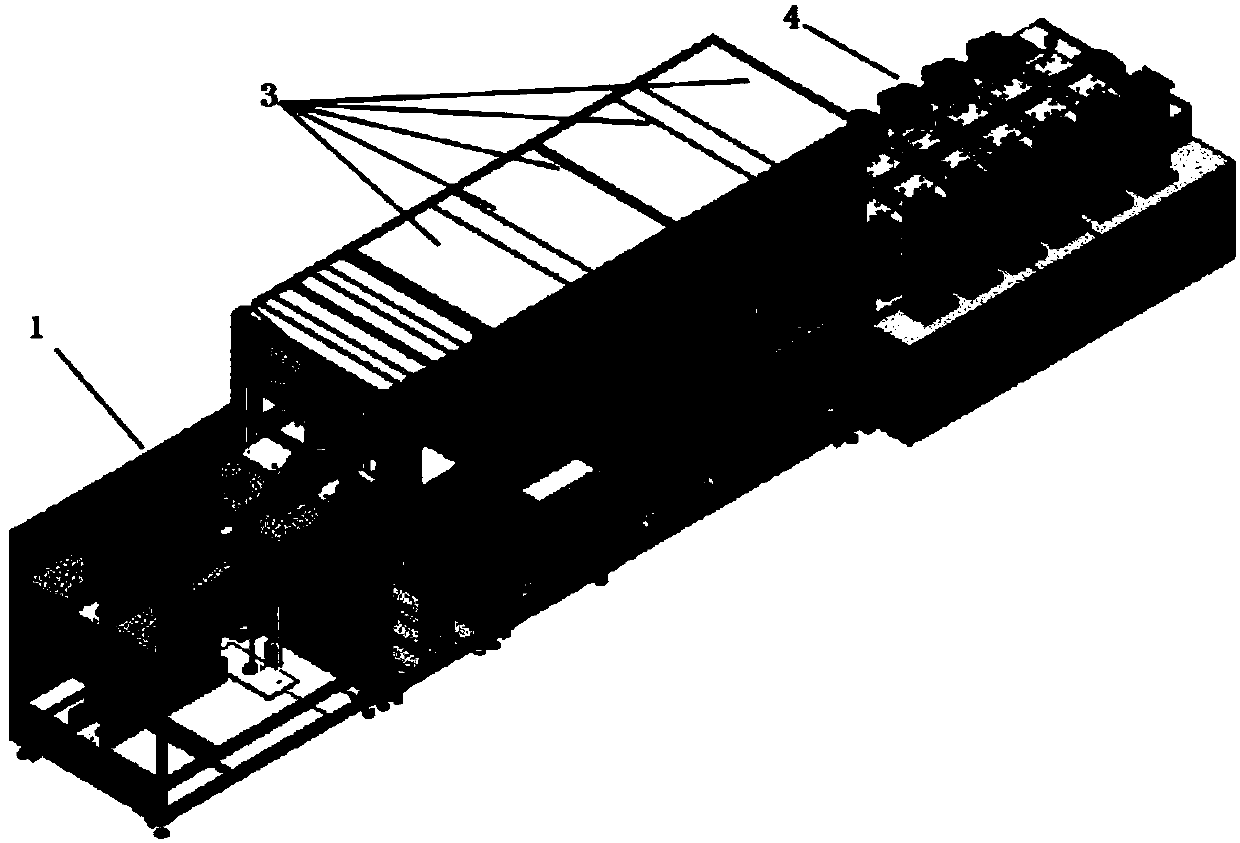

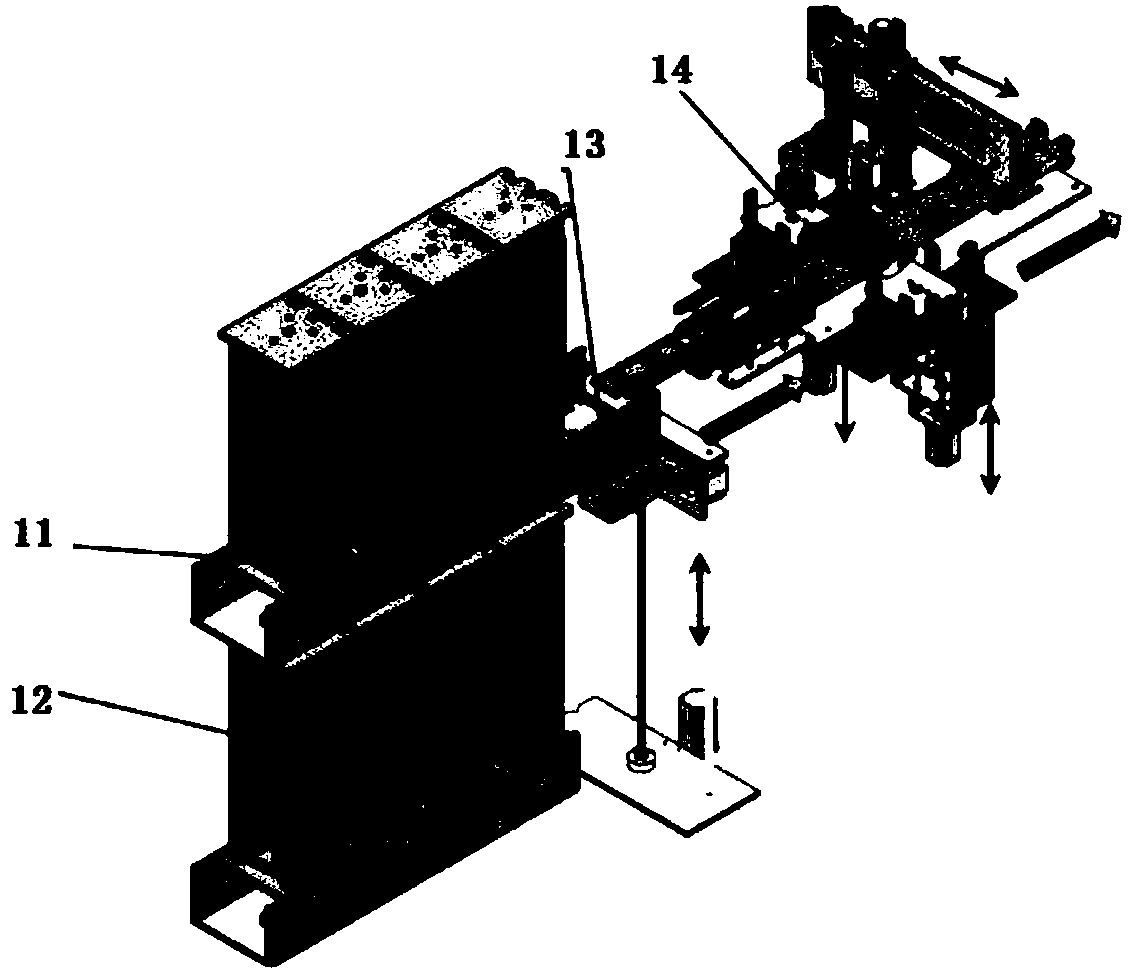

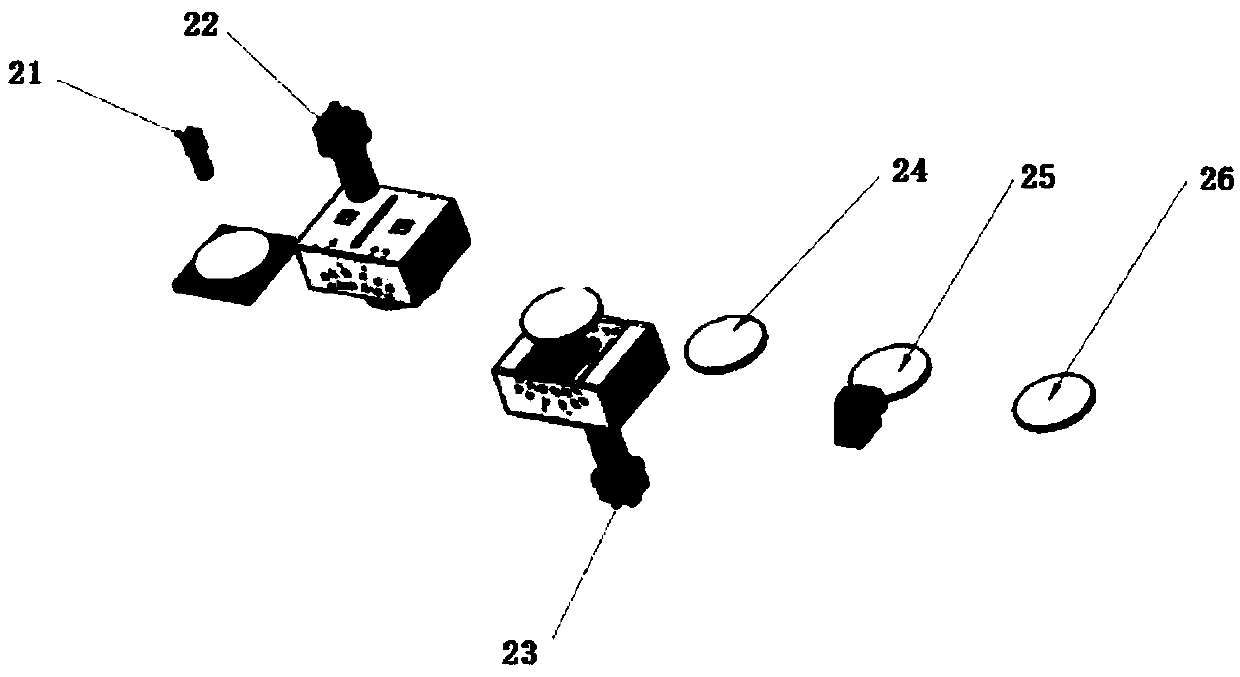

[0041] Such as Figure 1-4 As shown, this example is an automatic sorting device for silicon wafers, including a feeding part 1, a detection part 2 and a feeding part 3 arranged in sequence, and the detection part 2 includes a transmission mechanism, a positioning mechanism 21, a surface detection module, and a geometric parameter detection Module 24 and resistivity detection module 25, wherein, the transmission mechanism is arranged in the detection part 2, and the transmission mechanism adopts a belt transmission line, and the belt transmission line runs through the detection part for transmitting the silicon wafer; the positioning mechanism 21 is arranged at the starting point of the transmission mechanism At the beginning, the silicon wafers in the basket are positioned; the surface detection module includes an upper surface detection module 22 and a lower surface detection module 23, which are arranged on the side and top of the transmission mechanism to detect appearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com