A method for comprehensively debugging that whole process of a building electromechanical system

A technology of electromechanical systems and debugging methods, which is applied in the direction of instruments, data processing applications, database design/maintenance, etc., can solve the problem of low debugging efficiency of electromechanical systems, waste of time for debugging personnel, construction personnel and suppliers, and prolonging the debugging time of electromechanical systems, etc. problem, to achieve the effect of improving debugging efficiency, improving experience, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

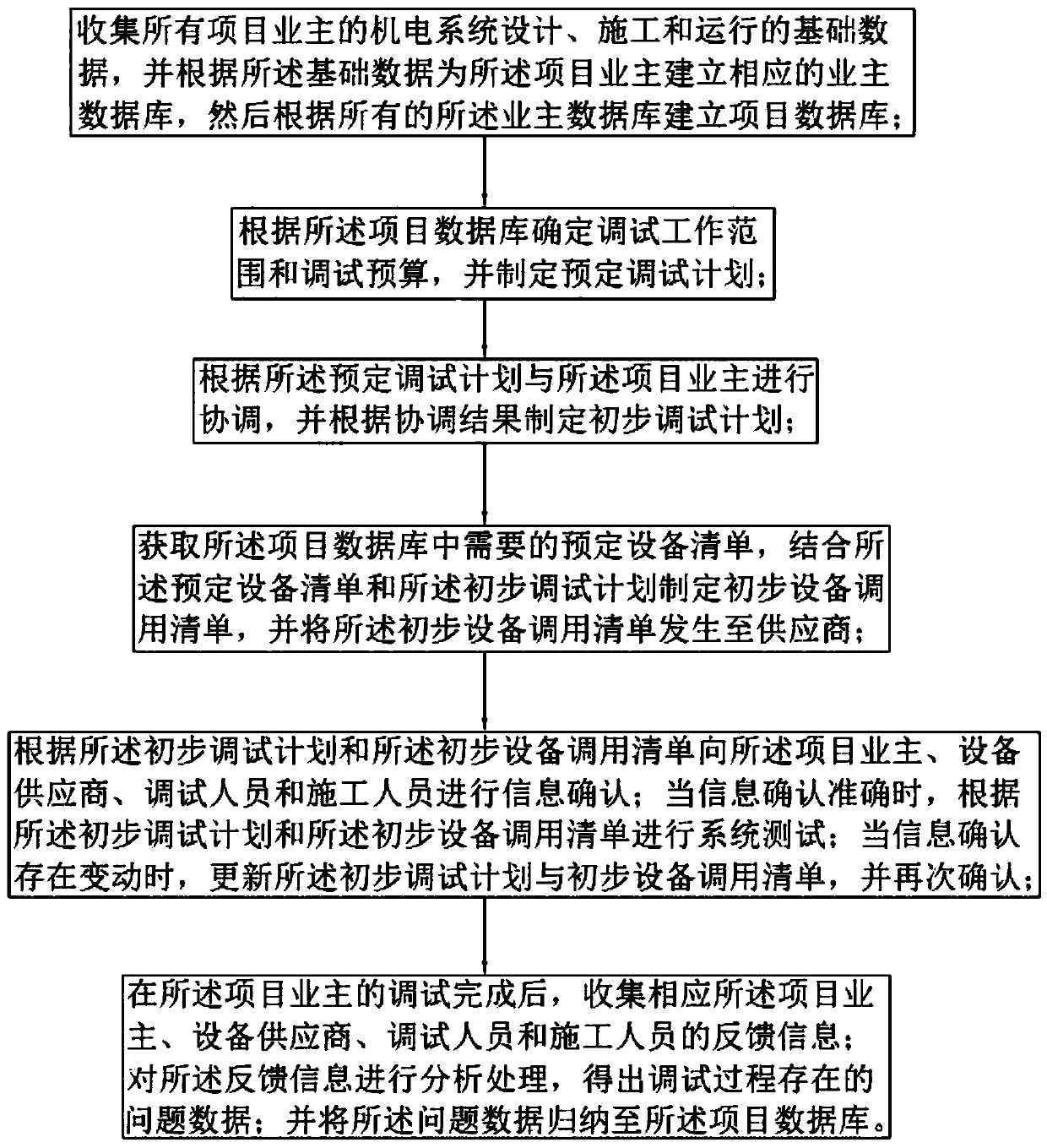

[0025] Embodiment: a comprehensive debugging method for the whole process of building mechanical and electrical systems, such as figure 1 shown, including the following steps:

[0026] Step 1. Collect the basic data of mechanical and electrical system design, construction and operation of all project owners, and establish corresponding owner databases for project owners based on the basic data, and then build project databases based on all owner databases.

[0027] Step 2: Determine the commissioning work scope and commissioning budget according to the project database, and formulate a scheduled commissioning plan.

[0028] Step 3: Coordinate with the project owner according to the scheduled commissioning plan, and formulate a preliminary commissioning plan based on the coordination results.

[0029] Step 4: Obtain the scheduled equipment list required in the project database, formulate a preliminary equipment call list in combination with the scheduled equipment list and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com