A method for simulating the aging of asphalt aqueous solution

A simulation method, the technology of aqueous solution, applied in the field of materials, can solve the problems of reduced service life, lack of aging process of asphalt aqueous solution, increase of pits and grooves in asphalt pavement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

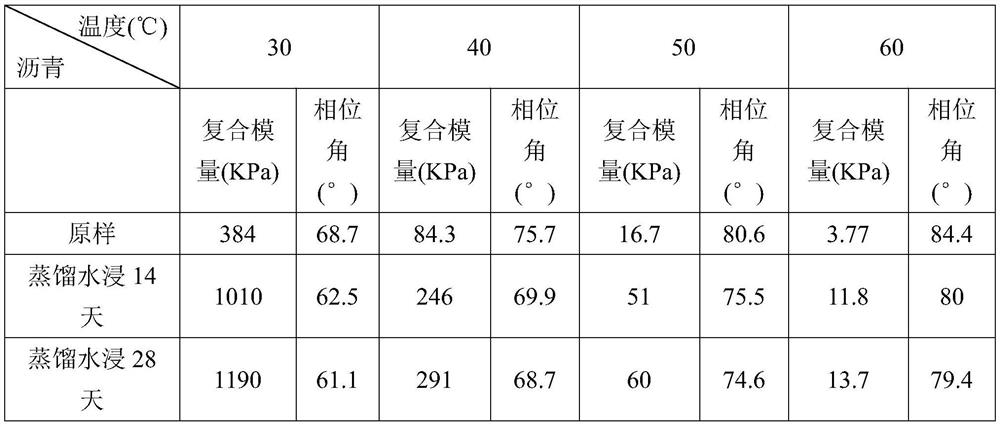

Embodiment 1

[0018] Preparation of aqueous solution

[0019] Take 100ml of distilled water.

[0020] Preparation of Asphalt Membrane Specimens

[0021] Take 15 grams of 70# asphalt that has been thermally aged in a film heating oven at 163°C for 5 hours, and pour it directly into a glass dish with a diameter of 15 cm and a height of 3 cm, and self-leveling to form an asphalt film specimen with a thickness of about 0.85 mm. Pour 100ml of distilled aqueous solution into a glass dish, and soak it at 40°C for 14 days and 28 days respectively to carry out the water aging test.

[0022] After the soaking time is up, take out 15ml of the aqueous solution to test the organic carbon content of the aqueous solution; rinse the asphalt surface with distilled water, then dry the glass dish containing the asphalt in an oven at 120°C for 1 hour, and cool it to room temperature for at least one day before taking it out Do the following test.

[0023] Water-aged asphalt performance test

[0024] The dr...

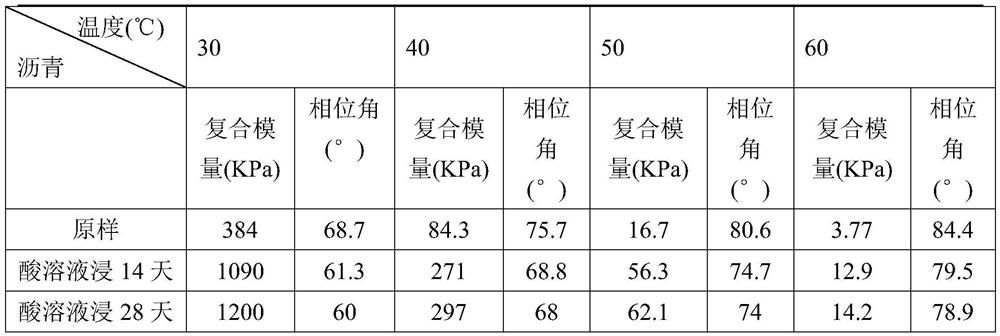

Embodiment 2

[0036] Preparation of aqueous solution

[0037] Prepare 100ml of an aqueous solution with a pH value of 3 using the stepwise dilution method with sulfuric acid to simulate an acid rain solution.

[0038] Preparation of Asphalt Membrane Specimens

[0039] Take 15 grams of 70# asphalt that has been thermally aged in a film heating oven at 163°C for 5 hours, and pour it directly into a glass dish with a diameter of 15 cm and a height of 3 cm, and self-leveling to form an asphalt film specimen with a thickness of about 0.85 mm. Inject 100ml of the acid solution into glass dishes and soak them at 40°C for 14 days and 28 days respectively to carry out the water aging test.

[0040] After the soaking time is up, take out 15ml of the aqueous solution to test the organic carbon content of the aqueous solution; rinse the asphalt surface with distilled water, then dry the glass dish containing the asphalt in an oven at 120°C for 1 hour, and cool it to room temperature for at least one d...

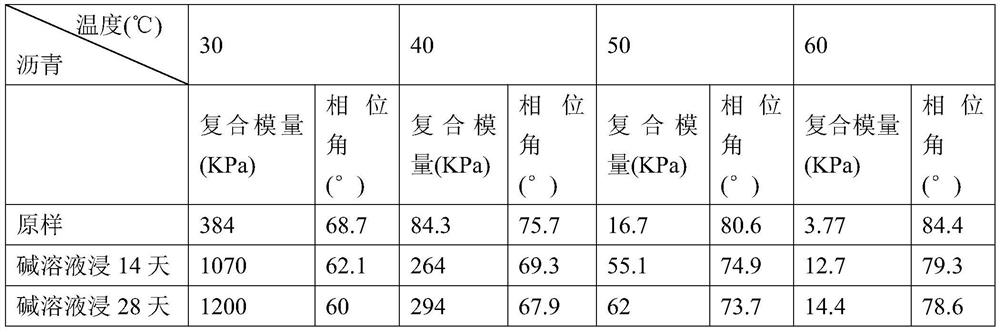

Embodiment 3

[0054] Preparation of aqueous solution

[0055] Use NaOH to prepare 100ml of alkaline solution with a pH value of 11 to simulate alkaline aqueous solution.

[0056] Preparation of Asphalt Membrane Specimens

[0057] Take 15 grams of 70# asphalt that has been thermally aged in a film heating oven at 163°C for 5 hours, and pour it directly into a glass dish with a diameter of 15 cm and a height of 3 cm, and self-leveling to form an asphalt film specimen with a thickness of about 0.85 mm. Inject 100ml of alkali solution into a glass dish and soak at 40°C for 14 days and 28 days respectively for water aging test.

[0058] After immersion, take out 10ml of the aqueous solution to test the organic carbon content of the aqueous solution; rinse the surface of the asphalt with distilled water, then dry the glass dish containing the asphalt in an oven at 120°C for 1 hour, and cool it to room temperature for at least one day before taking it out for use. Test below.

[0059] Water-age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com