Straight-top type ultrahigh pressure piston pressure gauge with automatic weight adding

A piston-type pressure gauge and straight-top technology, which is applied in the field of precision instruments, can solve problems such as slow loading of weights, increased error rates, and complex software, so as to ensure simplification and easy realization, and improve the measurement pressure. range, the effect of high system security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

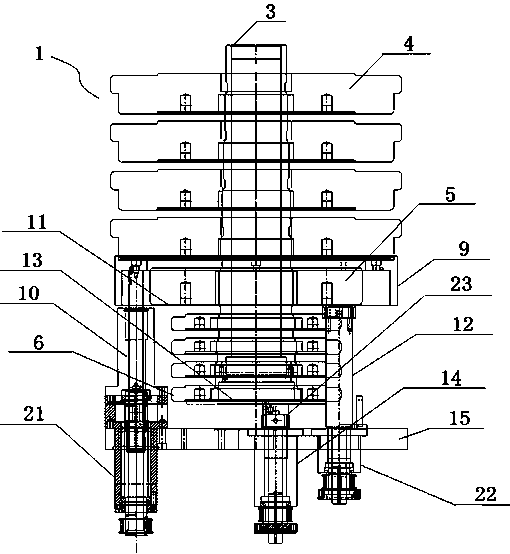

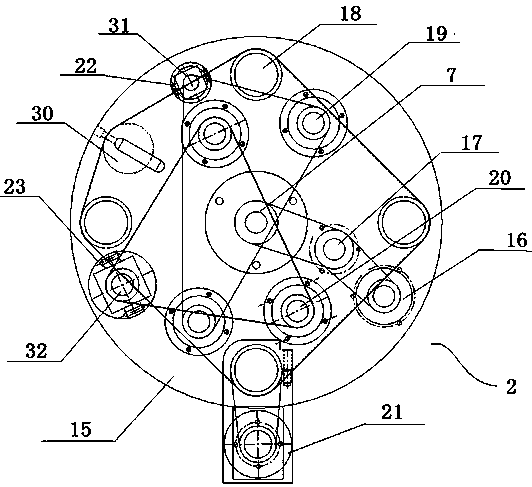

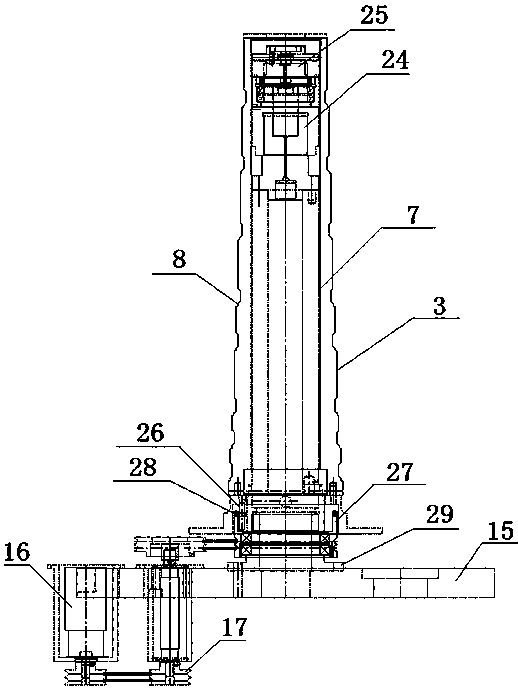

[0024] A straight top ultra-high pressure piston pressure gauge with automatic weighting, the pressure gauge includes a weight selection system 1 and a bottom drive system 2;

[0025] The weight selection system 1 includes a tower-shaped hanging basket 3, four 50-kg large weights 4, a 25-kg medium weight 5 and four 5-kg small weights 6. The tower-shaped hanging basket 3 The quality of the tower is five kilograms, and the corresponding maximum pressure can be 500MPa. The tower-shaped hanging basket 3 is sleeved on the central axis 7, and nine ring-shaped steps 8 are arranged on the outer wall of the tower-shaped hanging basket 3. The outer diameters of the nine steps 8 become larger sequentially from top to bottom, and the large weight 4, the middle weight 5 and the small weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com