Test tool for coating suspender

A spreader and inspection tool technology, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of large root shaking, squeezing by maintenance operators, and difficulty in ensuring the uniformity of the positioning pins of the spreader.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

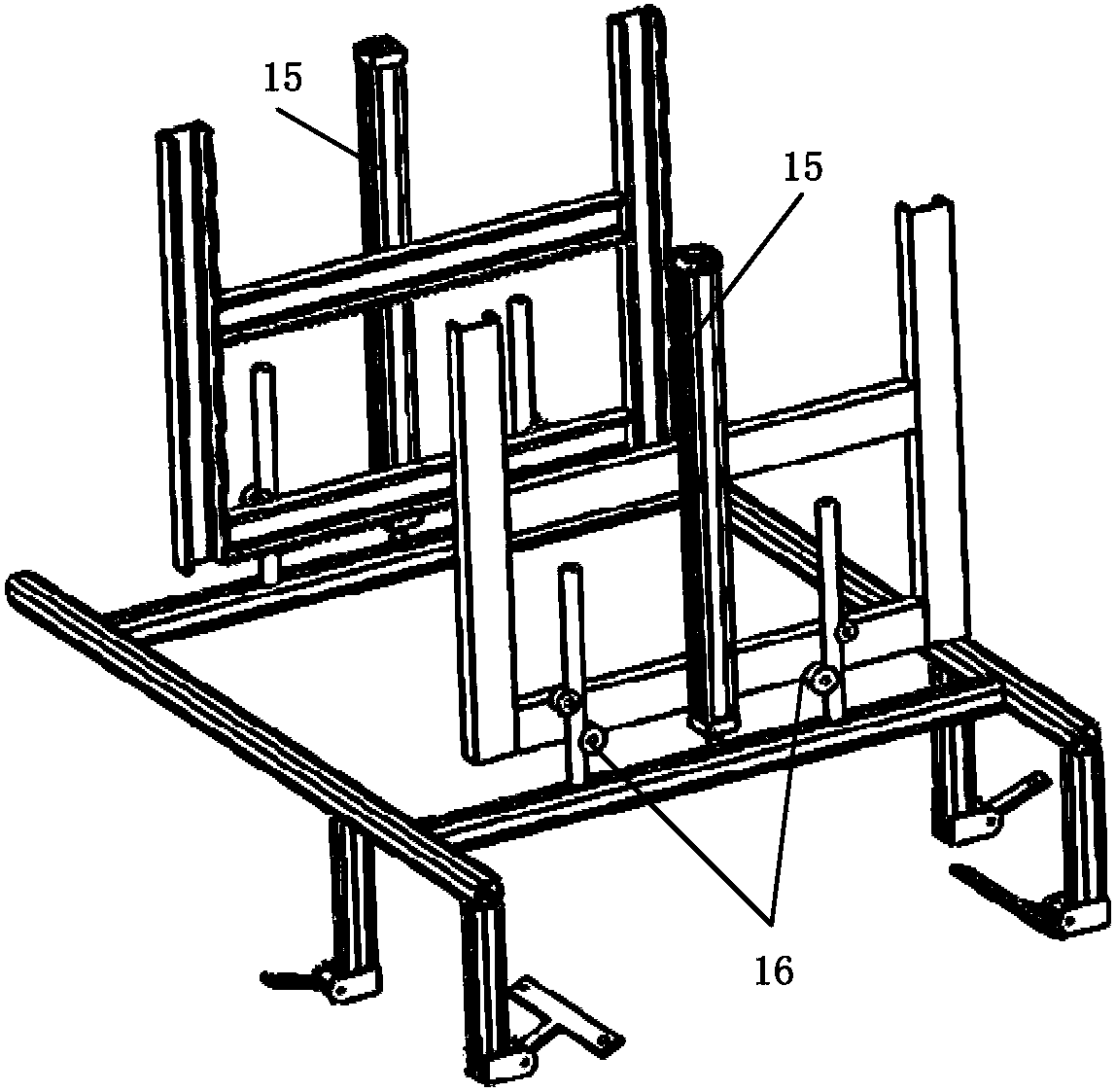

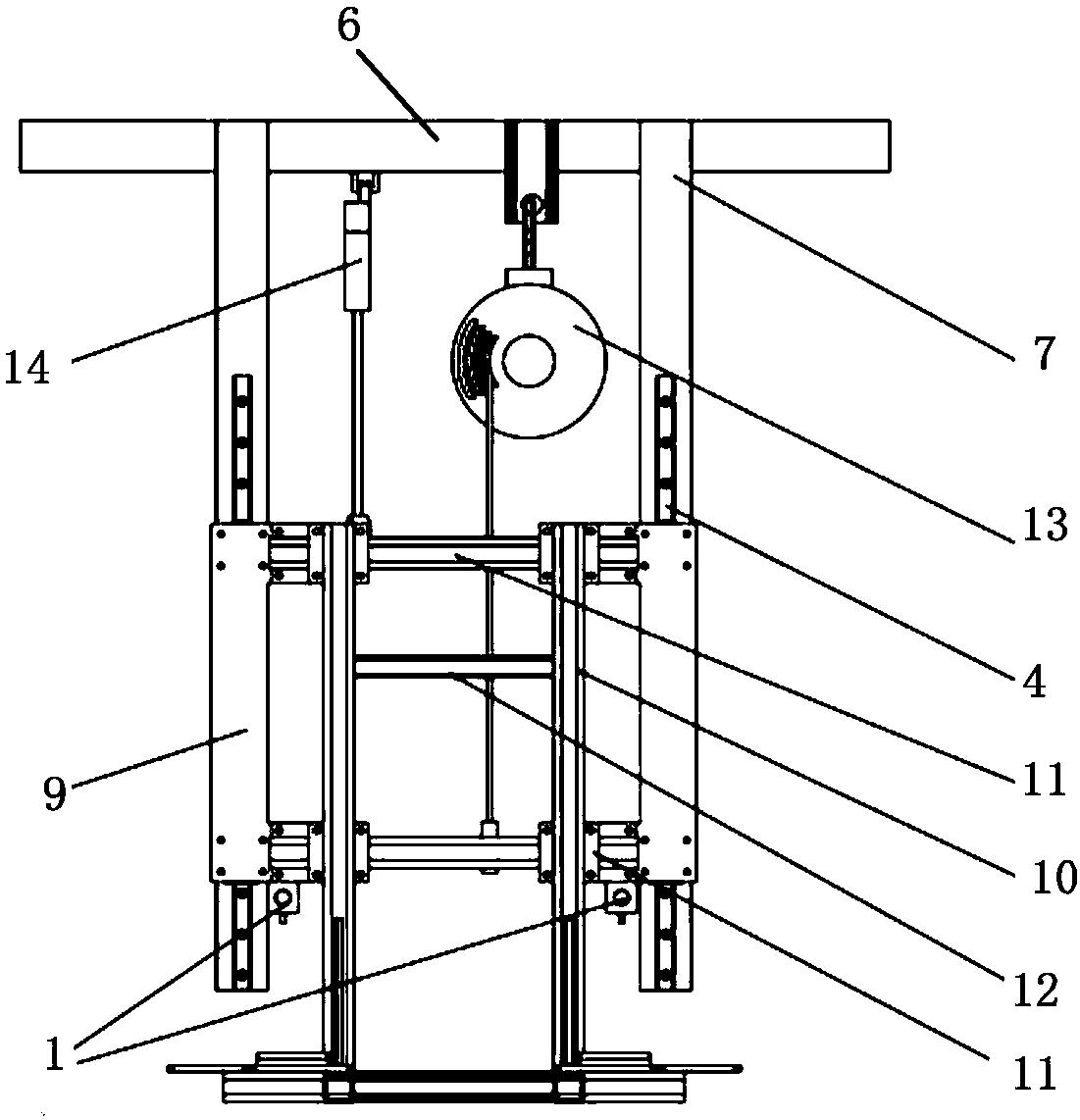

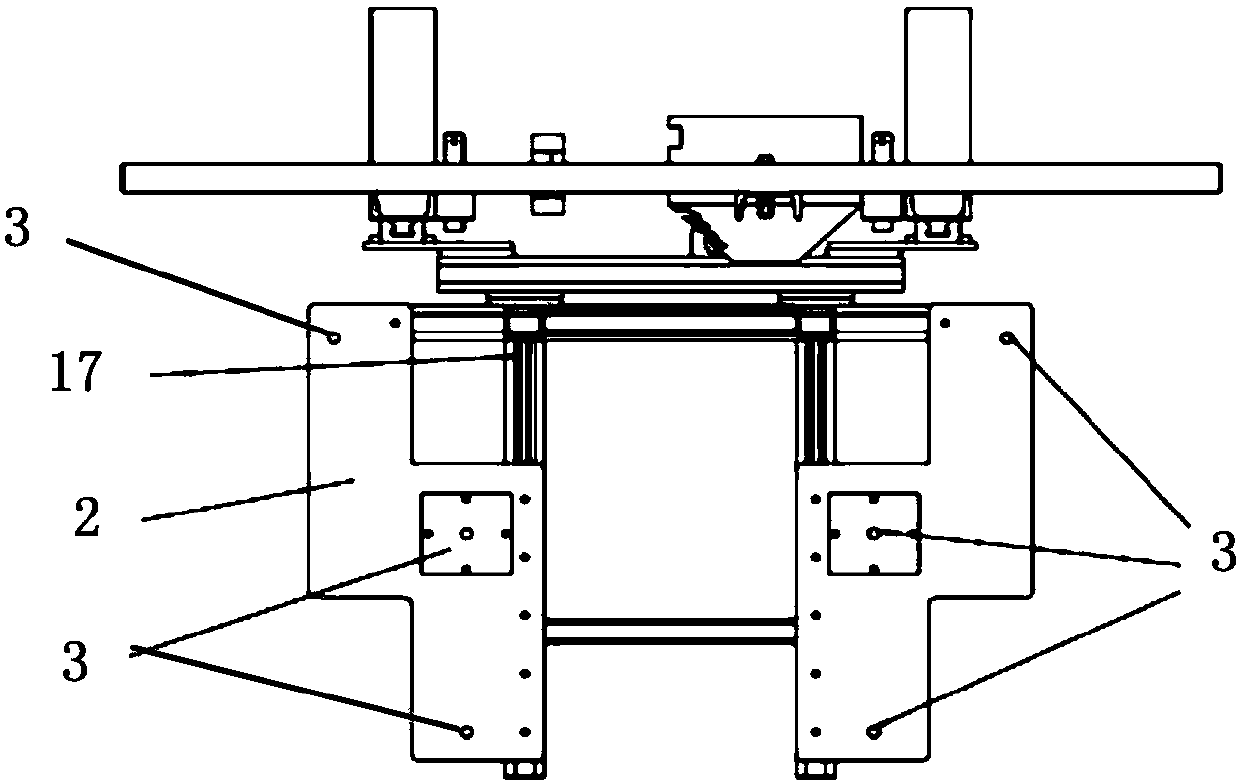

[0032] The following with attached Figure 2 to Figure 7 The inspection tool device of a coating hanger of the present invention will be further described in detail.

[0033] A checking device for a coating spreader of the present invention, please refer to Figure 2-7 , including a load-bearing frame, a locking device 1, a lifting frame, a positioning plate 2 and at least one positioning hole 3, the load-bearing frame is detachably fixed on the steel beam of the factory building, and the lift frame is slidably connected to the load-bearing frame up and down. The locking device 1 is detachably fixed on the lower part of the lifting frame, the locking device 1 is releasably locked and connected to the carrying frame, the positioning plate 2 is detachably fixed on the lifting frame, and the positioning hole 3 Distributed at intervals on the positioning plate 2, the positioning holes 3 correspond to the positions of the positioning pins of the spreader, and the positioning holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com