Material sorting and feeding system

A material and feeding technology, applied in the field of material sorting and feeding system, can solve problems such as unmanned, intelligent, affecting sorting efficiency, disrupting material flow, etc., to reduce the number of manual feeding, The overall structure is simple, and the effect of increasing the cache situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

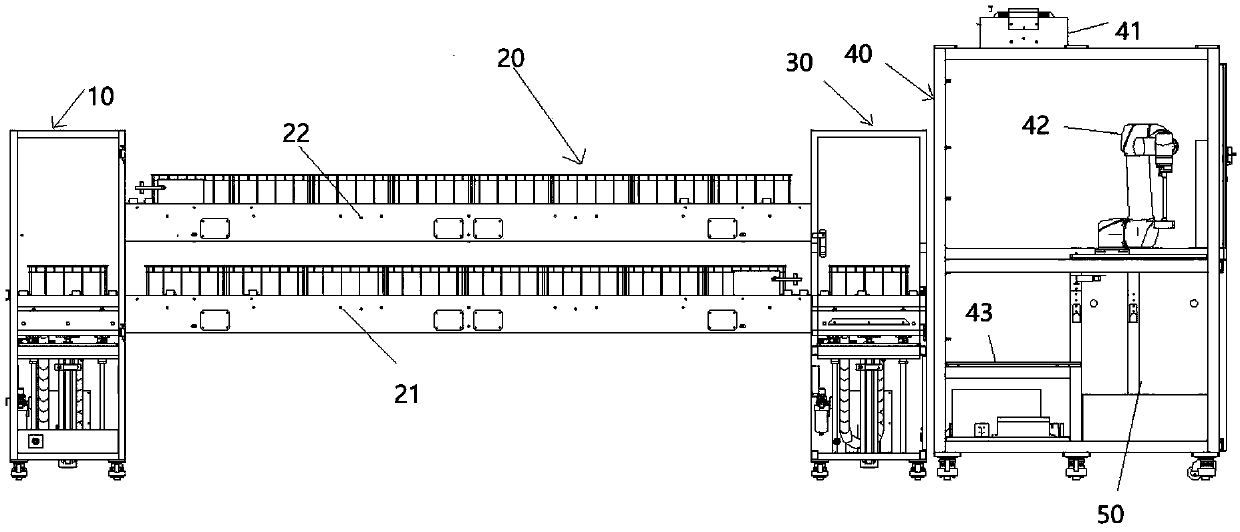

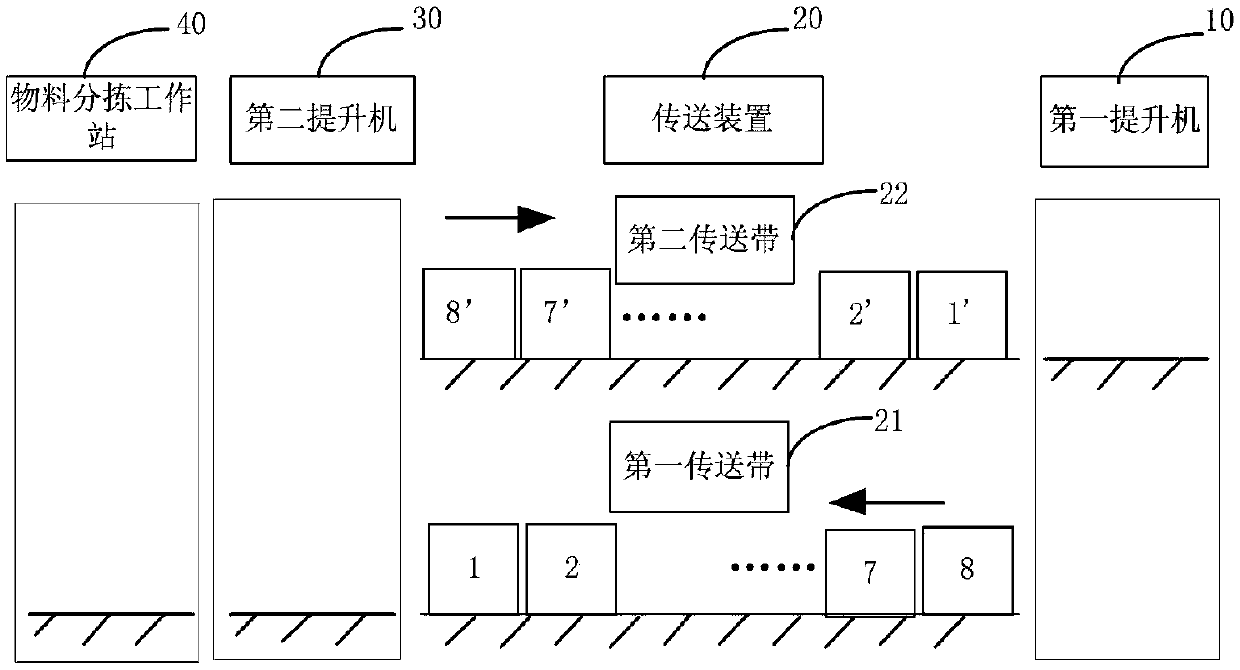

[0029] A material sorting and feeding system, such as figure 1 As shown, it includes a first hoist 10, a conveying device 20, a second hoist 30, a material sorting workstation 40 and a control device 50, wherein:

[0030] The conveying device 20 includes a first conveying belt 21 and a second conveying belt 22 with opposite conveying directions. The first conveyor belt 21 and the second conveyor belt 22 may be transmission mechanisms such as a belt line, a drum line, or a double-speed chain.

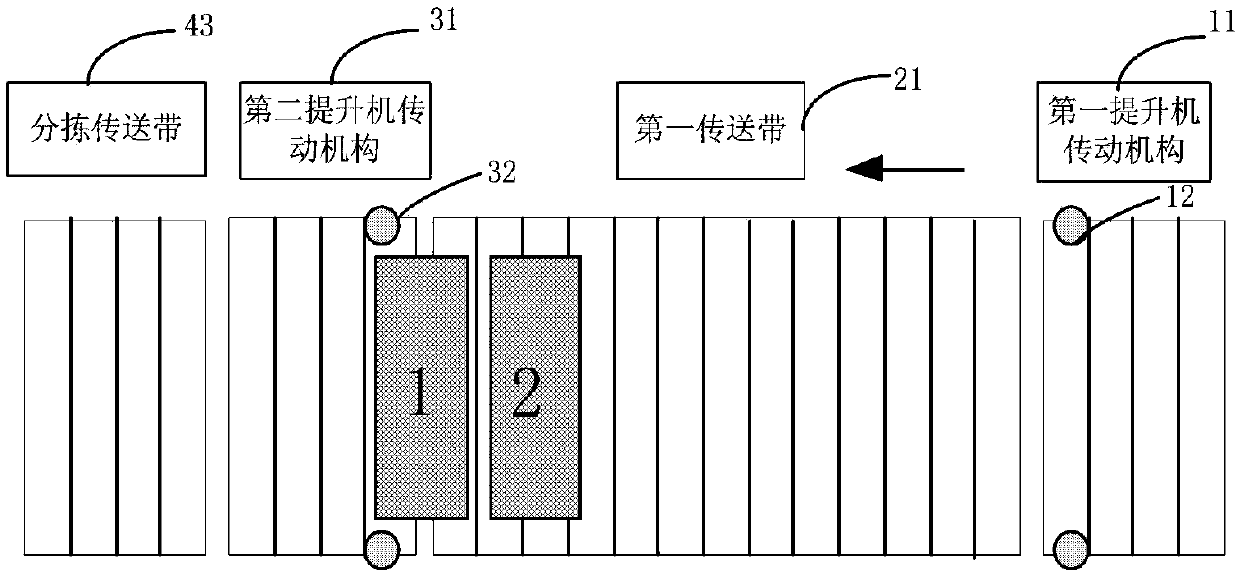

[0031] The first elevator 10 is used for delivering the material box to the first conveyor belt 21 or receiving the material box from the second conveyor belt 22 . The second elevator 30 is used to transfer the material box to the material sorting workstation 40 or the second conveyor belt 22 or receive the material box from the first conveyor belt 21 or the sorting workstation 40 . In order to ensure that the transmission speed of the material box is consistent, preferably the first h...

Embodiment 2

[0049] Compared with the first embodiment, the main difference of this embodiment is that the first conveyor belt 21 and the second conveyor belt 22 are also provided with a locking device 23 .

[0050] Because there may be differences in the frictional force between the first conveyor belt 21 and the second conveyor belt 22 and each material box when they move, the distance that the material boxes are transmitted is different, such as Figure 4 The situation shown in which No. 8 material box occupies the position of No. 1' material box due to the short conveying distance disrupts the process of cyclic loading. To solve this problem, combine the Figure 5-1 , Figure 5-2 As shown, the clamping device 23 can be set at the preset position of the first conveyor belt 21 and the second conveyor belt 22 (for example, at the tail of the first conveyor belt 21 and the second conveyor belt 22 in the direction of transmission), and the control device 50 is also used to set the Before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com