Box carrying clamp

A fixture and box technology, which is applied in the field of fixtures for transporting boxes, can solve the problems of complex fixtures and poor versatility, and achieve the effects of maturity and simplicity, improved economy and reliability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

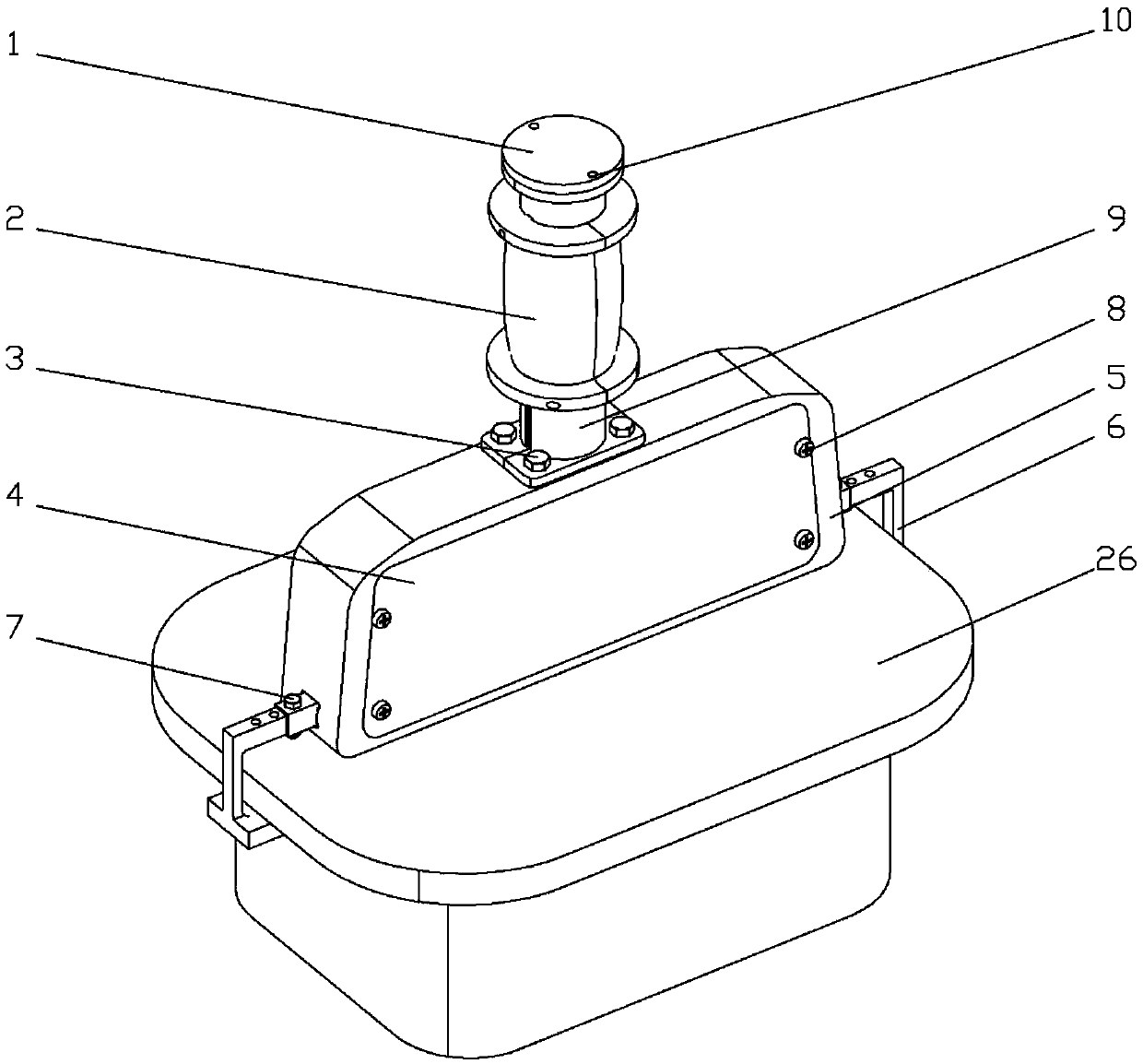

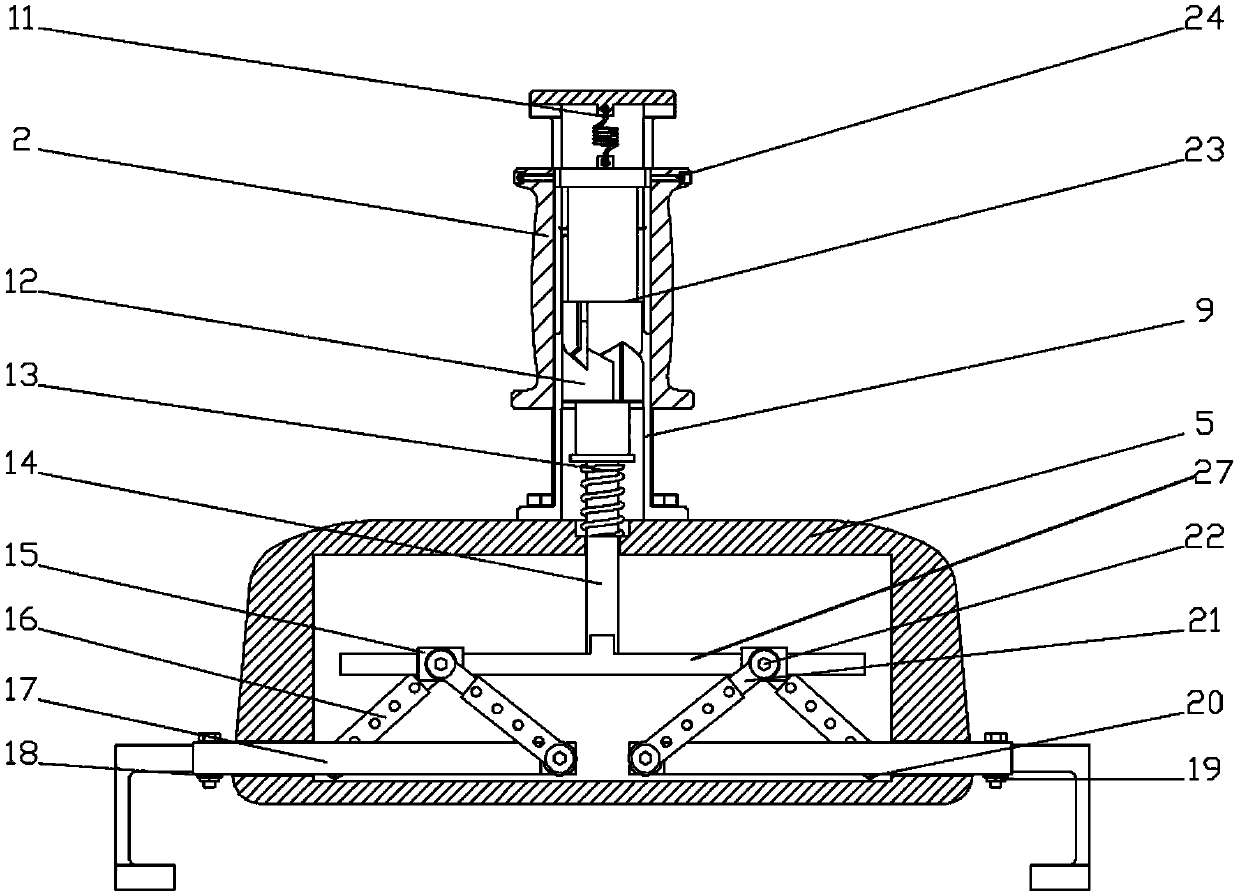

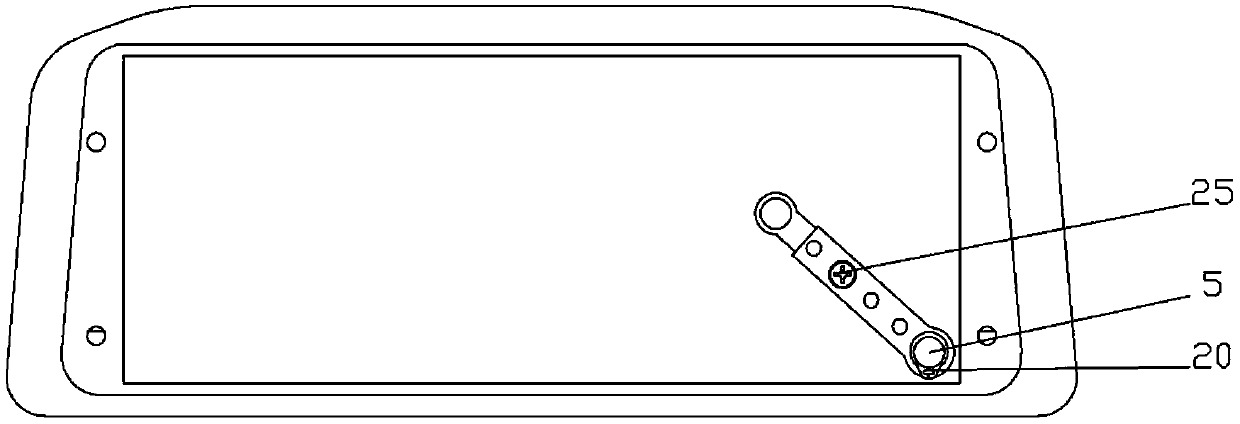

[0035] This embodiment provides a box carrying fixture for carrying the box 26, which includes a handle 2, an upper housing 9, an upper ratchet 23, an upper cover 1, a return spring 11, a lower ratchet 12, and a lower housing 5. Push rod 14, main spring 13, cross bar 27, left clamping assembly and right clamping assembly;

[0036] The handle 2 is sleeved on the outside of the upper casing 9 and can slide up and down along the outer wall surface of the upper casing 9; the side wall of the upper end of the upper casing 9 is provided with a length along its axial direction. A strip groove, the upper end of the handle 2 is fixed with the upper ratchet wheel 23 by a handle screw 24. At this time, the upper end of the upper ratchet wheel 23 is formed with a protrusion matching the elongated groove, and When the upper ratchet 23 slides along the inner wall of the upper housing 9, the protrusion slides along the side wall of the elongated groove, so that there is no gap between the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com