Welding auxiliary tooling for air conditioning capillary

A technology of auxiliary tooling and capillary tubes, which is applied in the direction of welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of increasing the changeover time, welding auxiliary tooling cannot meet the generalization requirements, and achieve the effect of meeting the generalization requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

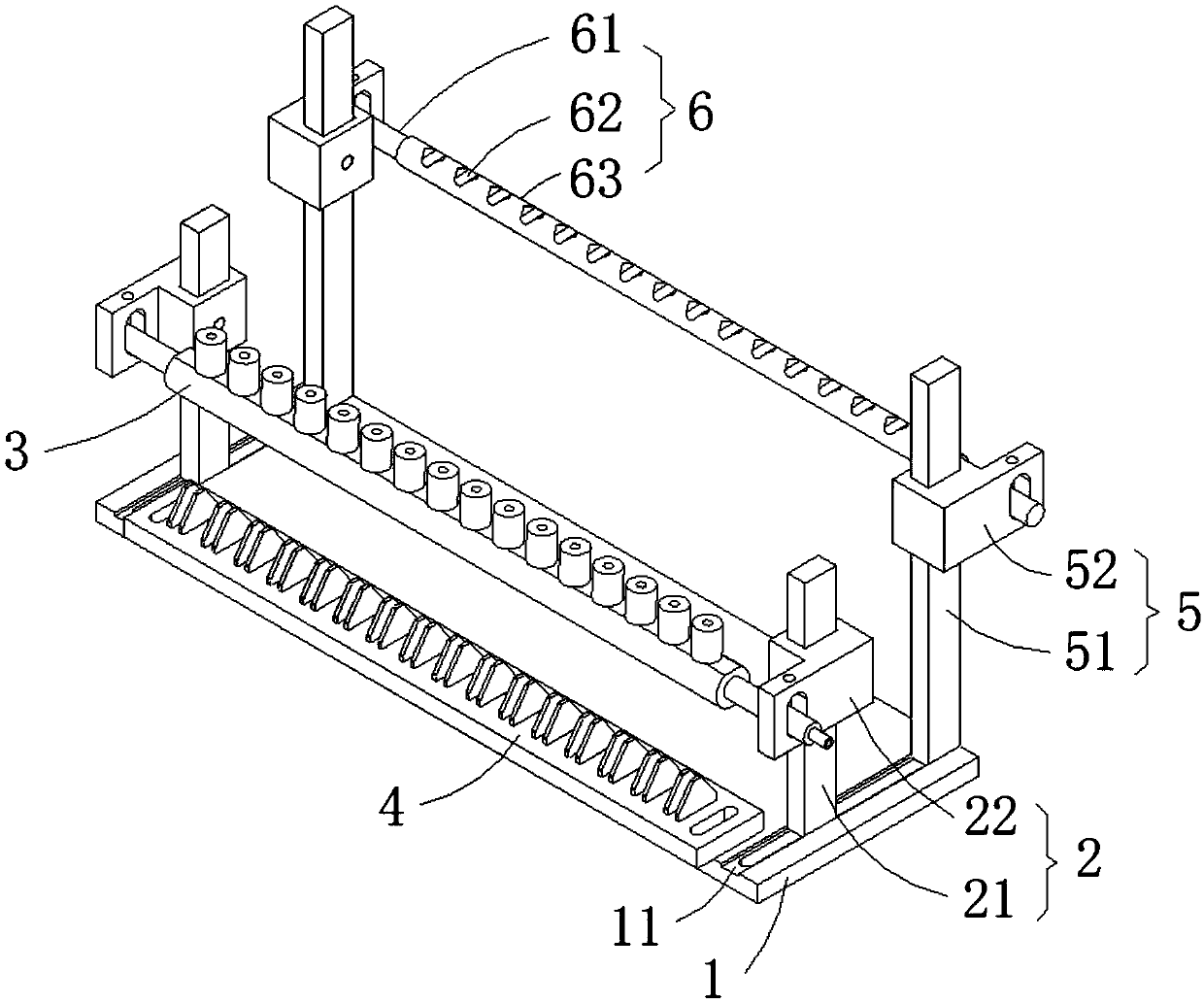

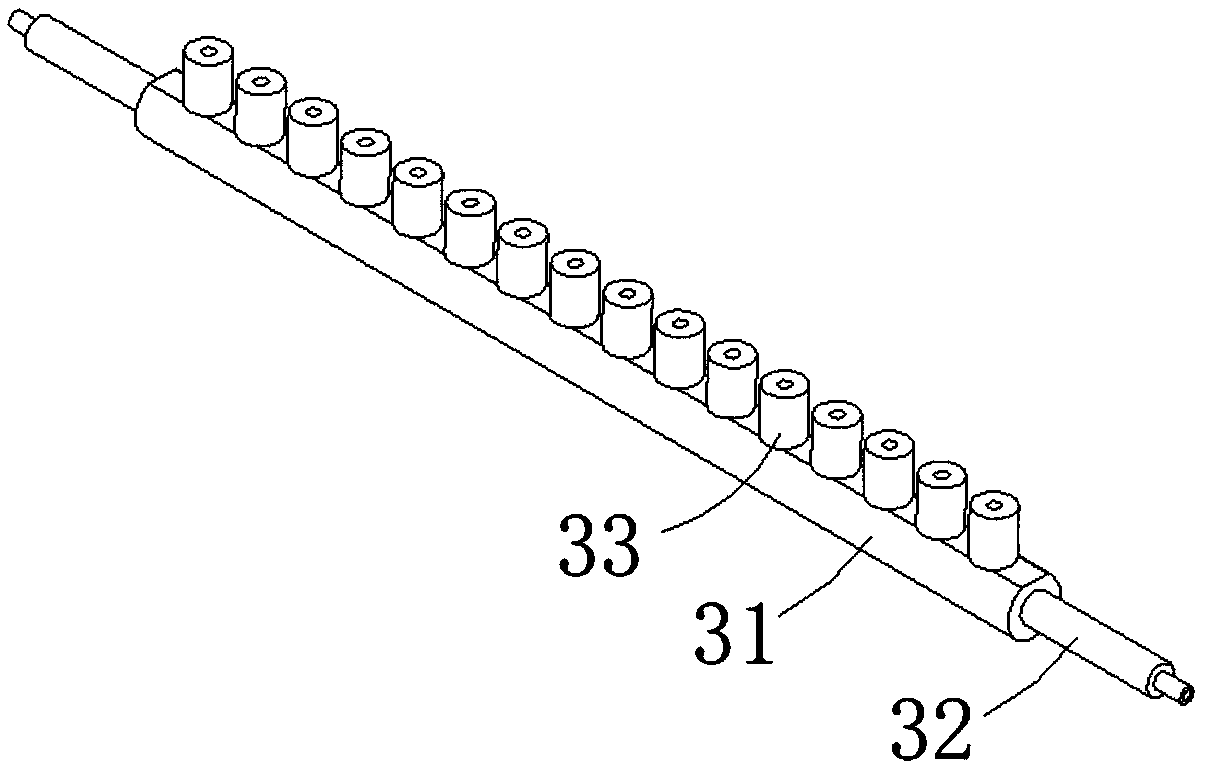

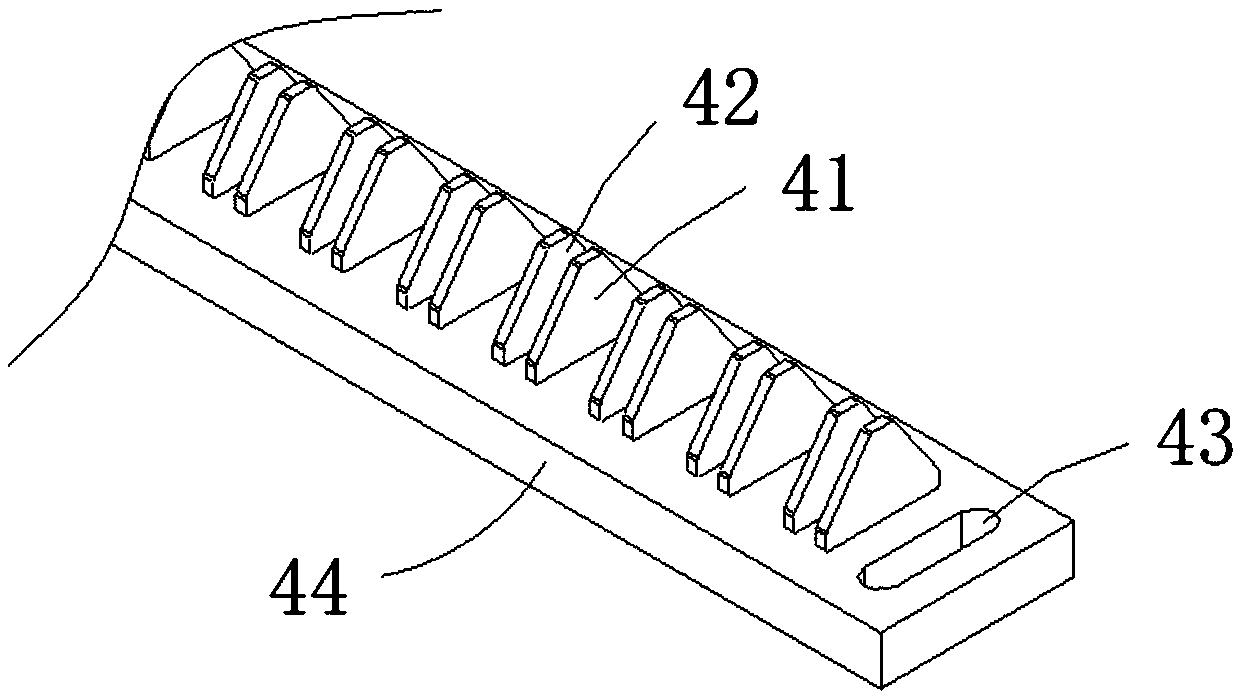

[0035] like Figure 1-4 As shown, a welding auxiliary tooling for an air-conditioning capillary 7 includes a base plate 1, a first support assembly 2 is provided on the base plate 1, and a nitrogen distribution assembly 3 is provided on the first support assembly 2; the nitrogen distribution assembly 3 is suitable for detachable connection And communicate with the capillary 7; the base plate 1 is also provided with a first positioning assembly 4, the first positioning assembly 4 is suitable for clamping the capillary 7; wherein, the first positioning assembly 4 and the first support assembly 2 can move relative to the base plate 1 and Fixed; the first support assembly 2 can adjust the distance between the nitrogen distribution assembly 3 and the bottom plate 1; the nitrogen distribution assembly 3 can rotate and be fixed relative to the first support assembly 2, thus, through the first support assembly 2, the nitrogen distribution assembly 3 and the A position change of the po...

Embodiment 2

[0047] like figure 1 , 5 As shown, different from the above-mentioned embodiments, the bottom plate 1 in this embodiment is also provided with a second support assembly 5, the second support assembly 5 is movable and fixed relative to the bottom plate 1, and the second support assembly 5 is provided with a second positioning assembly 6. The second support component 5 can adjust the distance between the second positioning component 6 and the bottom plate 1 , and the second positioning component 6 is suitable for clamping the capillary 7 . Therefore, the second positioning component 6 cooperates with the first positioning component to fix some heterosexual capillaries 7 .

[0048] In this embodiment, the second positioning assembly 6 includes a connecting rod, and the two ends of the connecting rod are provided with a second plug rod 61, and the rod body of the connecting rod is provided with a limiting groove 62, so that it can be clamped through the limiting groove 62. capil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com