Multifunctional bean dregs filter unit

A bean dregs filtration and multi-functional technology, applied in the direction of filtration separation, separation device, mobile filter element filter, etc., can solve the problems of mechanized production, high labor cost, time-consuming and labor-intensive, etc., to prevent the bean dregs from splashing and easy to operate , the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

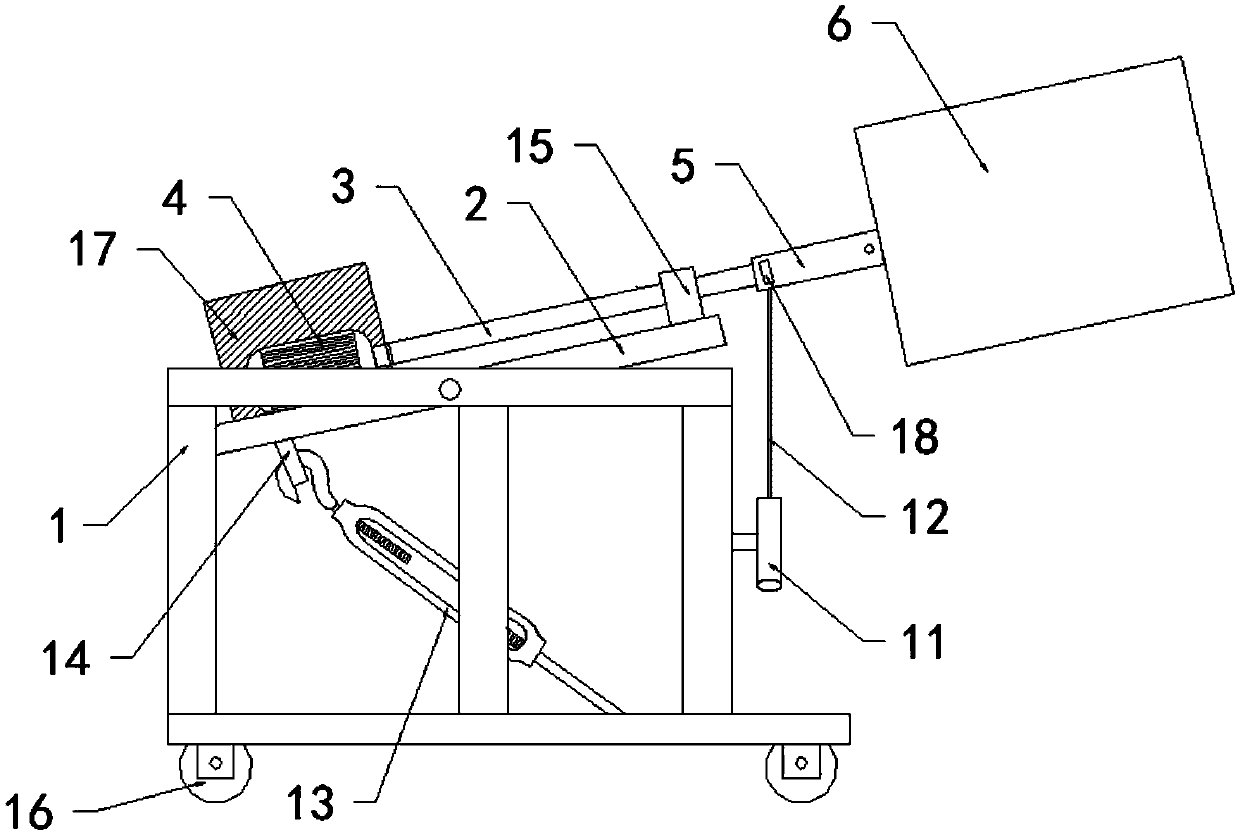

Embodiment 1

[0040] A kind of multi-functional bean dregs filtering device, comprises fixed frame 1, and the upper panel 2 upper part of fixed frame 1 is provided with rotating mechanism, and rotating mechanism comprises rotating shaft 3 and driving mechanism 4 that drives rotating shaft 3 to rotate, and rotating shaft 3 one end and driving mechanism 4 connected, the other end of the rotating shaft 3 is connected with an angle adjustment mechanism 5 and a filter barrel 6 in turn; the filter barrel 6 extends out of the upper panel 2;

Embodiment 2

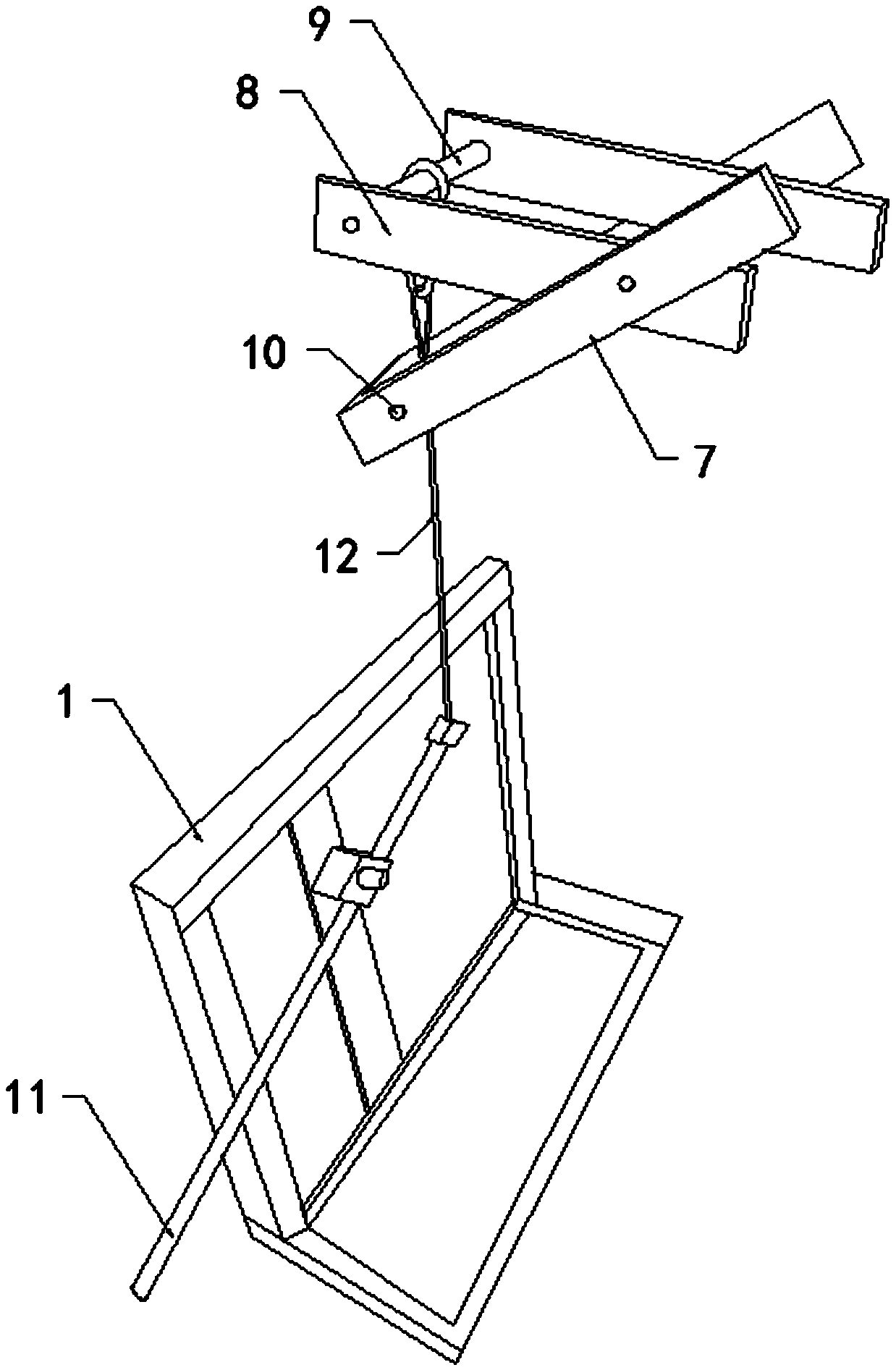

[0042] This embodiment is further optimized based on Embodiment 1. The angle adjustment mechanism 5 includes a first fork 7 and a second fork 8 sleeved inside the first fork 7;

[0043] The first fork frame 7 is connected to the end of the rotating shaft 3; one end of the second fork frame 8 extends out of the first fork frame 7 and is connected to the end of the filter bucket 6; the first fork frame 7 is located at one end of the second fork frame 8 and the second The two-fork frame 8 is hinged; the second fork frame 8 is located at one end of the rotating shaft 3 and is detachably connected with the first fork frame 7 .

[0044] The first fork frame 7 and the second fork frame 8 are simple in structure, ingenious in design, easy to operate and low in cost while realizing convenient adjustment of the inclination angle of filter barrel 6 when bean dregs are poured out.

Embodiment 3

[0046]This embodiment is further optimized based on Embodiment 2. The second fork frame 8 is located between the two sides of one end of the rotating shaft 3 and a sleeve 9 is provided. The first fork frame 7 is provided with a connecting hole 10 corresponding to the position of the sleeve 9, and the connecting rod 18 connects the first fork frame 7 and the second fork frame 8 through the sleeve 9 and the connection hole 10 .

[0047] Not only is it convenient to fix the first fork frame 7 and the second fork frame 8, but also when pouring out the bean dregs, the inclination angle of the filter barrel 6 can be adjusted by grabbing the sleeve 9, so as to control the speed of pouring out the bean dregs and prevent excessive speed from causing Bean dregs splash or burn the staff; the structure is simple, the design is ingenious, the operation is convenient, and the cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com