Automatic glass laminated sheet binding and wrapping device and binding and wrapping technology thereof

A coating device and lamination technology, which is applied to packaging, binding materials, and parts of binding machinery, etc., can solve the problems of small storage of glass pieces, damage and breakage of glass pieces, and low operating efficiency, so as to improve the binding efficiency and Quality, reduce the effect of membrane material collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

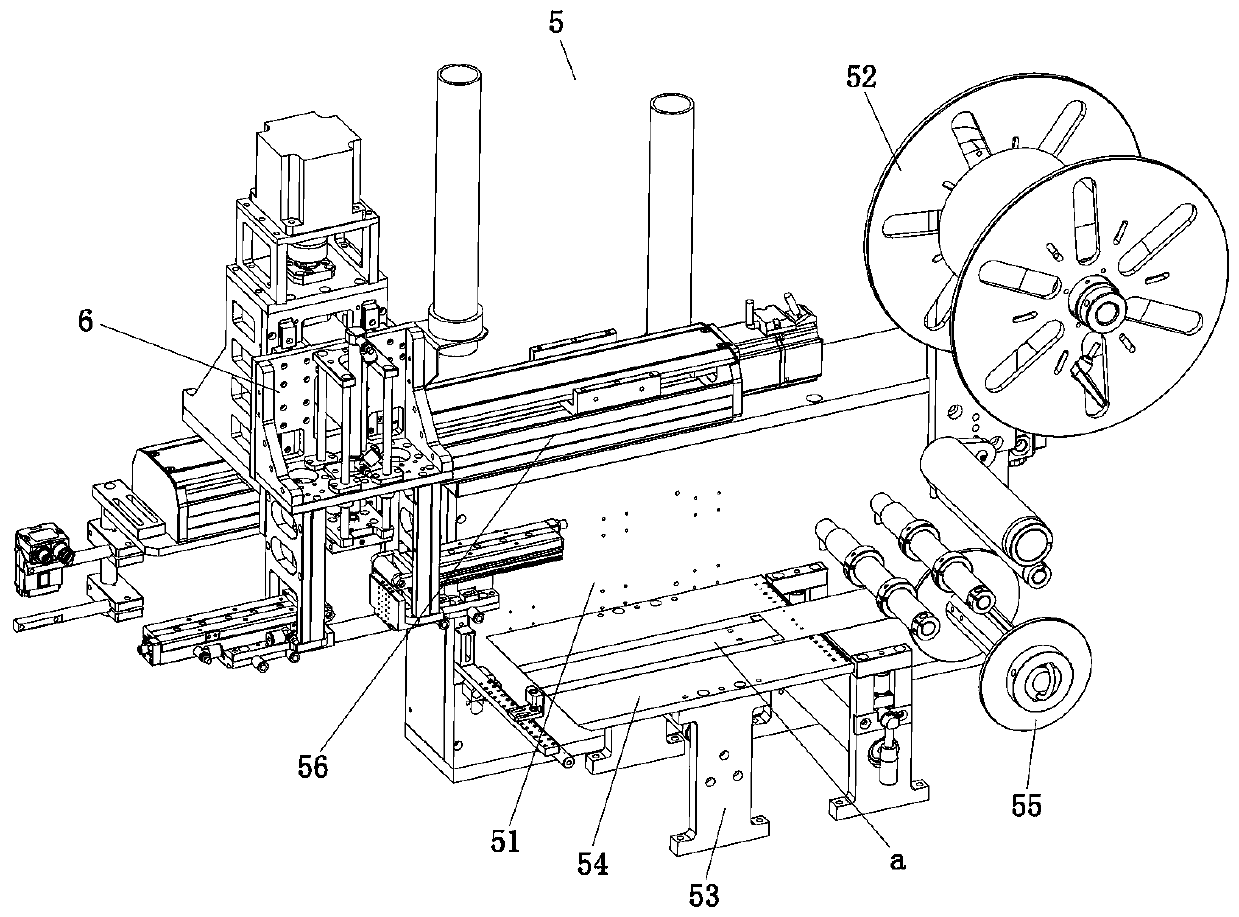

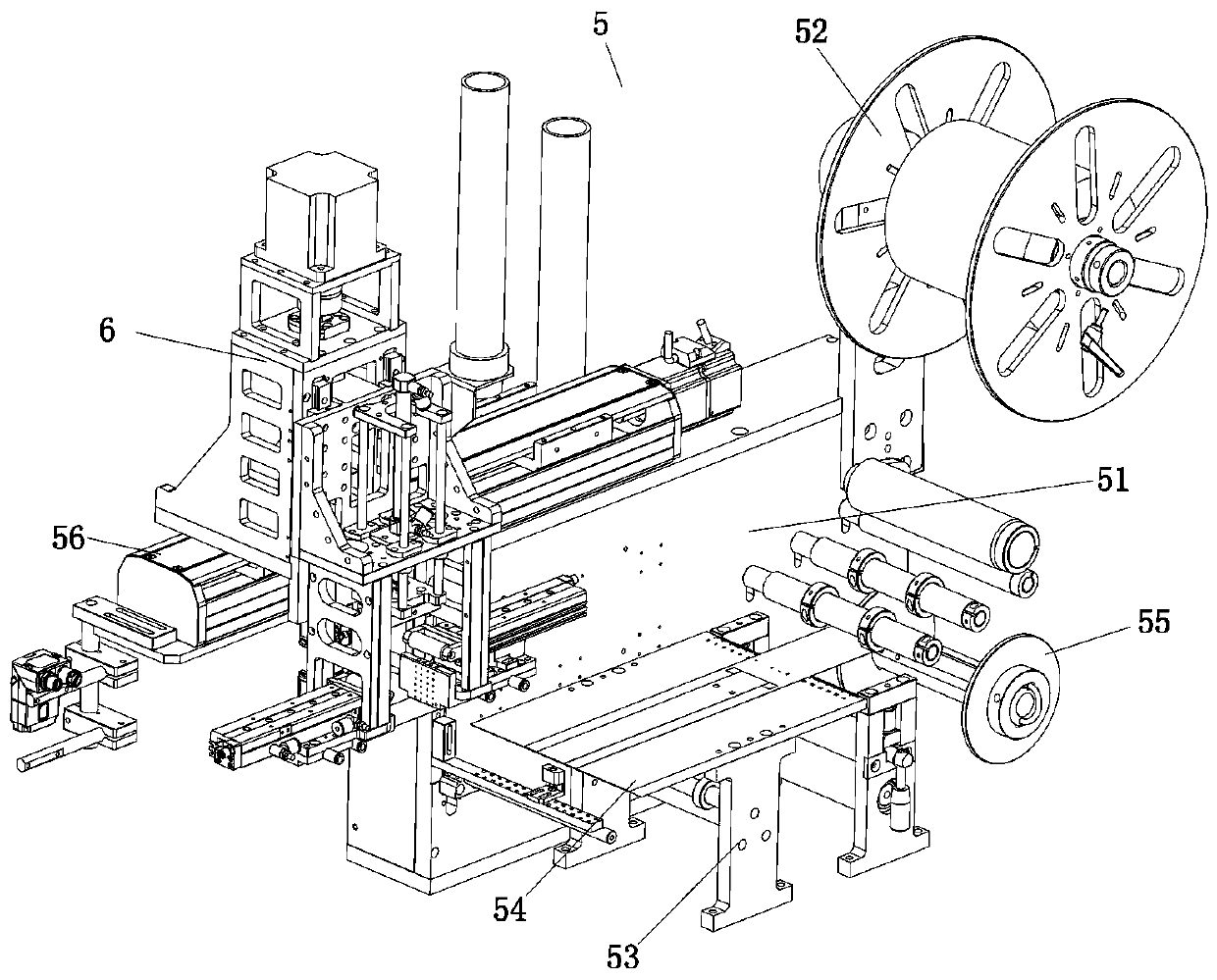

[0030] Such as Figure 1 to Figure 7 As shown, the technical solution adopted by the present invention is as follows: an automatic strapping and coating device for glass laminates, including a strapping assembly 5 and a strapping assembly 6, wherein the strapping assembly 5 includes a strapping support plate 51, a pulley 52, stripping plate 54, take-up pulley 55 and linear module 56; above-mentioned belt-out support plate 51 is vertically arranged on the frame, and belt pulley 52 is rotatably arranged on the side wall of belt-out support plate 51, and the belt pulley 52 is wound with a tape adhering to the adhesive tape a; the above-mentioned take-up pulley 55 is rotatably arranged on the side wall of the strip support plate 51, and is located below the pulley 52, and the end of the tape is connected and fixed on the take-up On the pulley 55; the above-mentioned peeling pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com