Control circuit for weighing sensor

A technology of weighing sensor and control circuit, applied in the direction of logic circuit interface device, detailed information of weighing equipment, logic circuit connection/interface layout, etc. Changes and other issues to achieve the effect of simple structure, flexible selection, and flexible matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

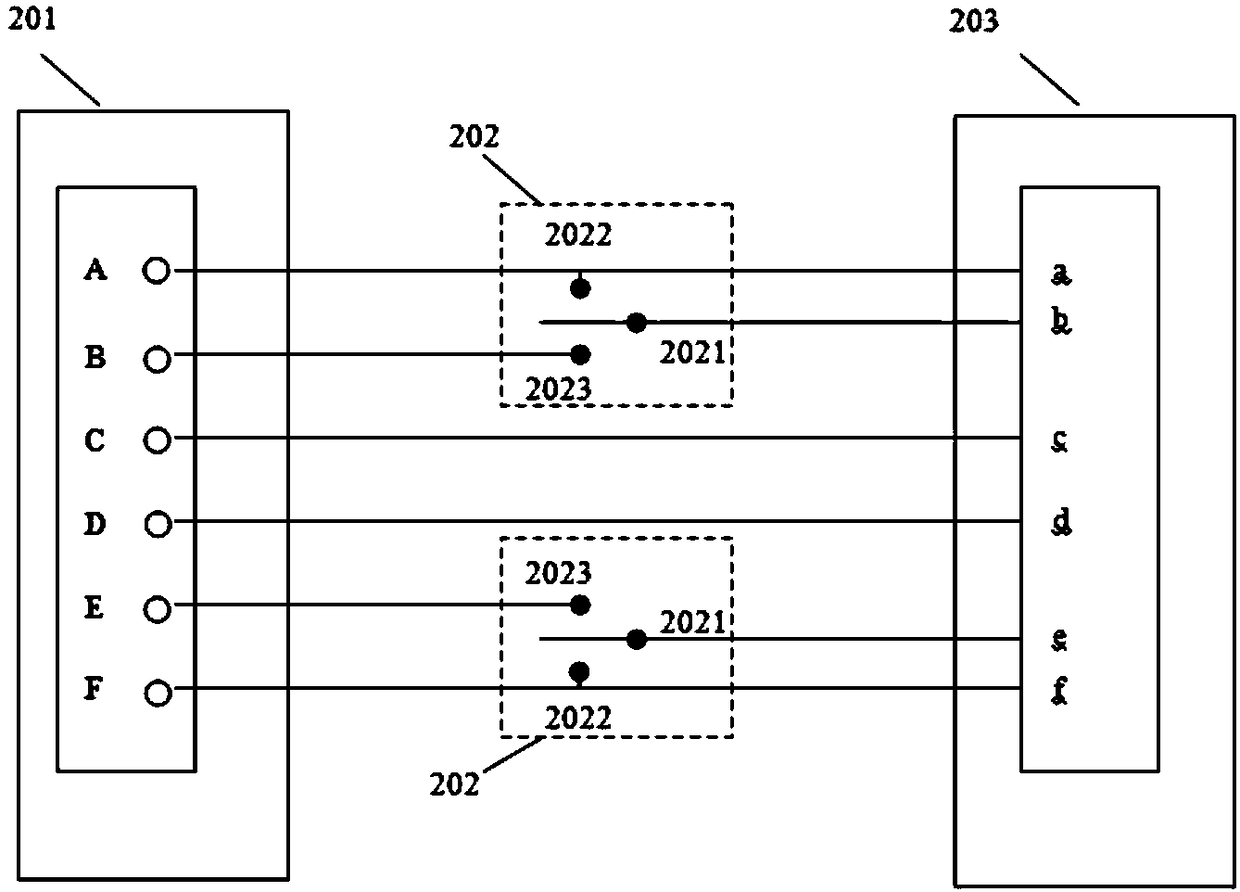

[0034] figure 2 It shows the connection structure diagram of the load cell and the six-wire signal processing equipment of the present invention.

[0035] like figure 2 As shown, the connector 201 includes six terminals A~F and the six interfaces a~f of the signal processing device 203 respectively correspond to excitation (+), feedback (+), output (+), output (-), excitation ( -) and feedback (-), terminals C and D are directly connected to interfaces c and d of the signal processing device 203 respectively, and an analog switch 202 is respectively set between terminals A and B, and between terminals E and F. When the signal processing device 203 is a six-wire system, the analog switch 202 is set so that the terminals A, B, E, and F are respectively connected to the interfaces a, b, e and f of the signal processing device 203; when the signal processing device 203 is a four-wire system , the analog switch 202 disconnects the terminals B and E, and only the terminals A and...

Embodiment 2

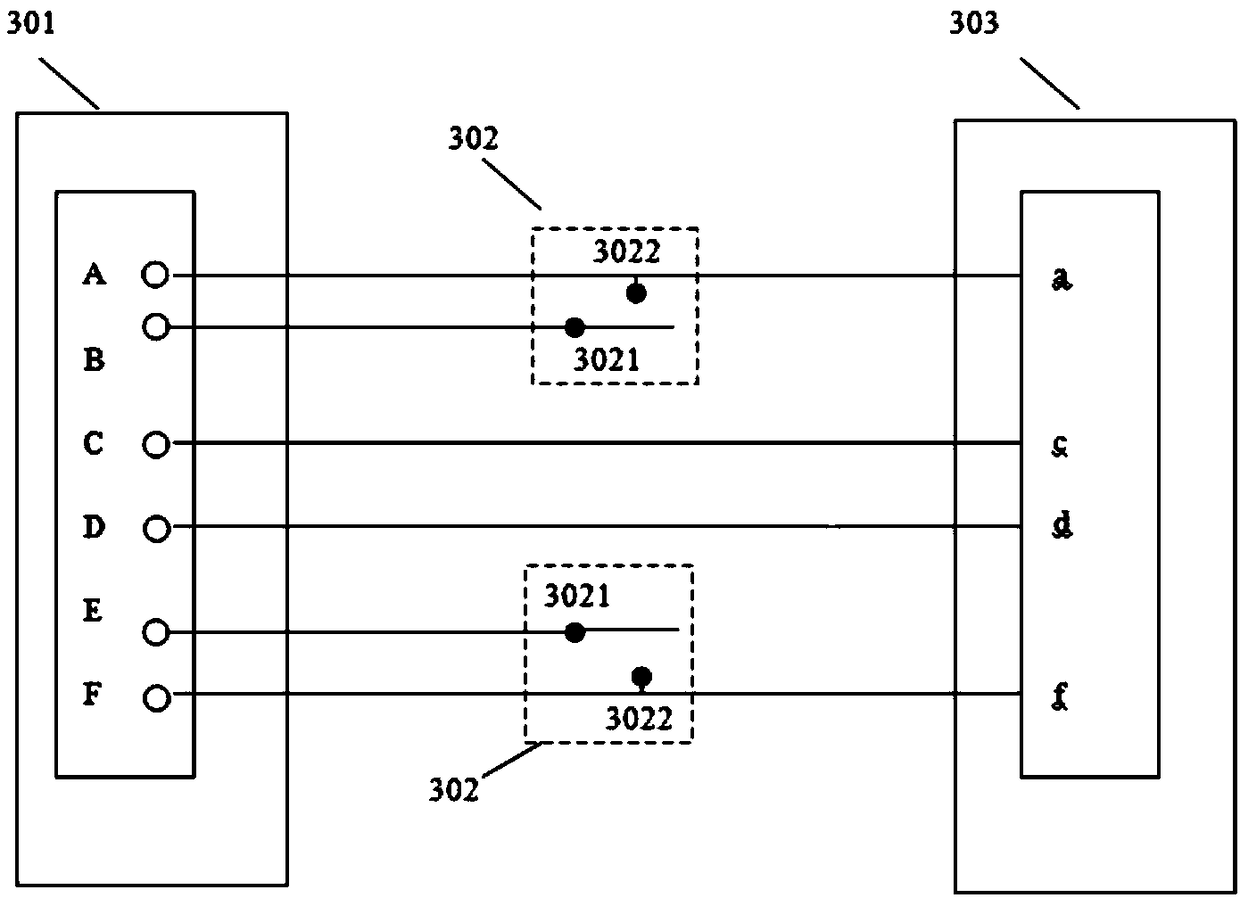

[0041] image 3 A connection structure diagram of the load cell and the four-wire signal processing device 303 of the present invention is shown.

[0042] like image 3As shown, the connector 301 includes six terminals A~F corresponding to excitation (+), feedback (+), output (+), output (-), excitation (-) and feedback (-), and the signal processing device 303 includes The four interfaces a, c, d and f correspond to excitation (+), output (+), output (-) and excitation (-) respectively, and terminals C and D are directly connected to interfaces c and d of the signal processing device 303 respectively. An analog switch 302 is provided between terminals A and B, and between terminals E and F, respectively. When the signal processing device 303 is a four-wire system, set the analog switch 302 so that terminals A and B are short-circuited, and terminals E and F are short-circuited, and then respectively connected to interfaces a and f of the signal processing device 303 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com