System for improving adhesion force of train wheel rail

An adhesive force, train wheel technology, applied in locomotives and other directions, can solve the problems of lack of applicability, increased wheel-rail adhesion, inability to apply braking and deceleration, etc., to achieve flexible adhesion control, increase adhesion, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

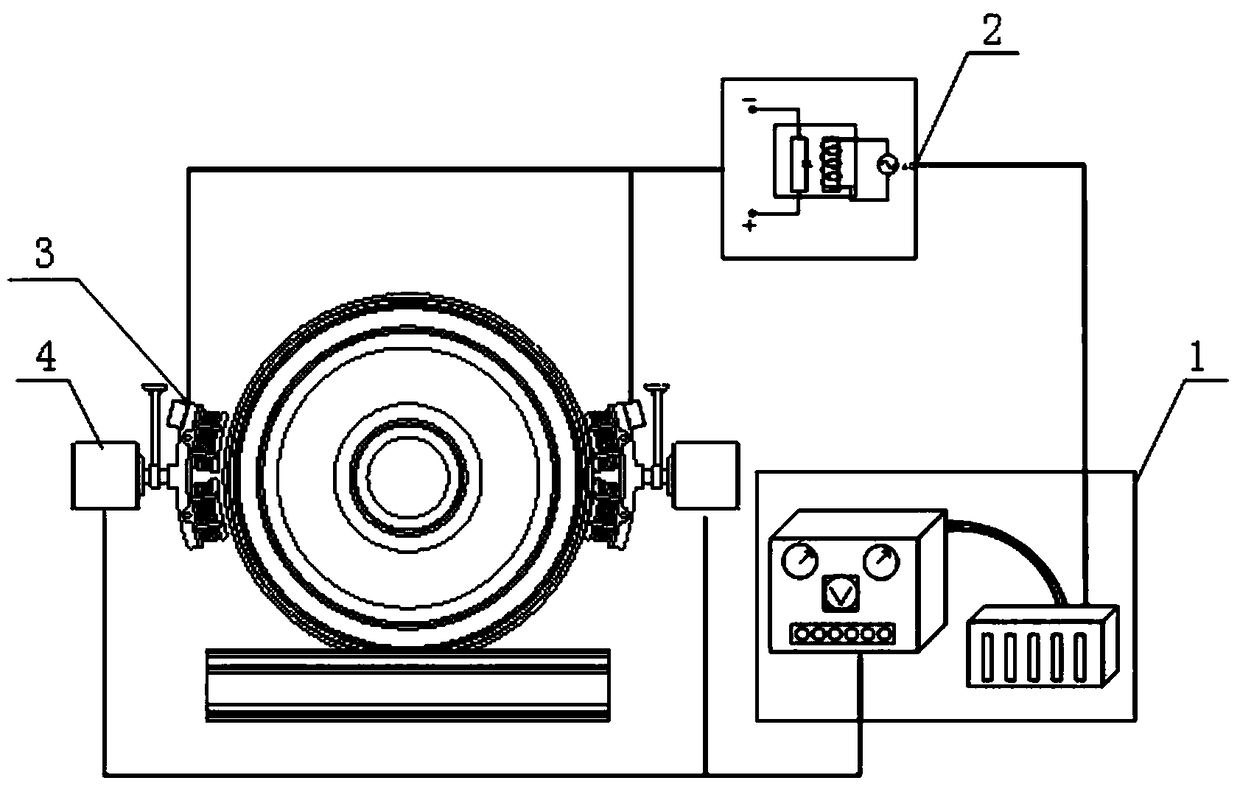

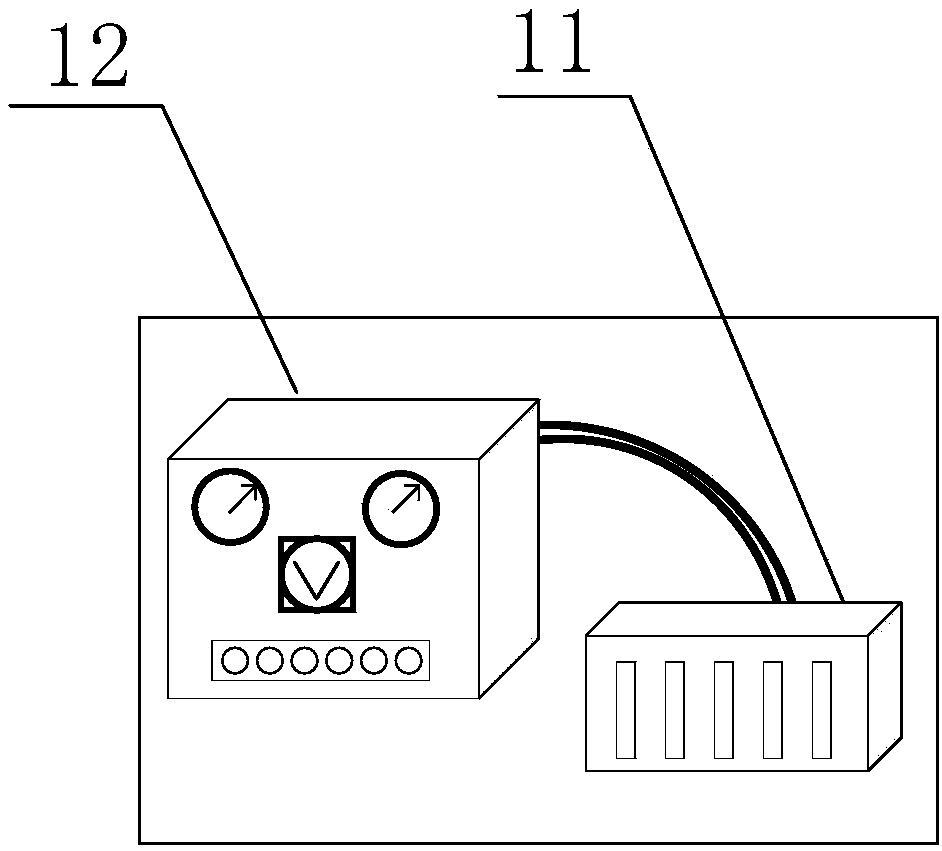

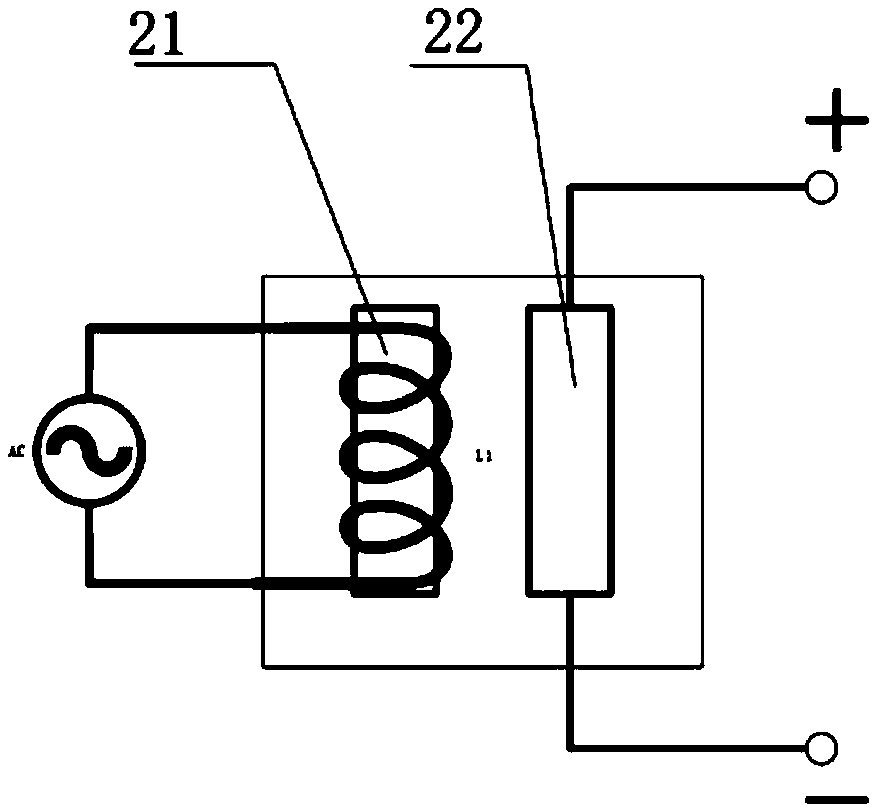

[0032] The system for improving the wheel-rail adhesion of trains includes sequential control device 1, excitation power supply 2, wheel tread electromagnetic device 3 and pneumatic propulsion device 4, see figure 1 , the wheel tread electromagnetic device 3 is non-contact suspended on both sides of the train wheel tread, the control device 1 includes an electronically controlled pneumatic device 11 and a microcomputer controller 12, see figure 2 , the excitation power supply 2 includes a power unit 21 and a regulator 22 connected to each other, see image 3 , the power unit 21 is a rectifier, the regulator 22 is used to adjust the size of the output excitation current, the wheel tread electromagnetic device 3 includes a cast iron friction block 31, a coil core 32, a yoke 33, an electromagnetic Iron bracket 34, junction box 35 and connecting plate 36, refer to Figure 4 One side of the electromagnet holder 34 is connected with a yoke 33, a coil iron core 32 and an iron frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com