Tabletting device for producing medical drugs

A tablet pressing device and a technology for drug production, which are applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of inconvenient control of the amount of pressed medicine, inconvenient tablet removal, high use limitations, etc., to achieve reduction Limitations of use, reduced tablet looseness, and reduced misplacement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

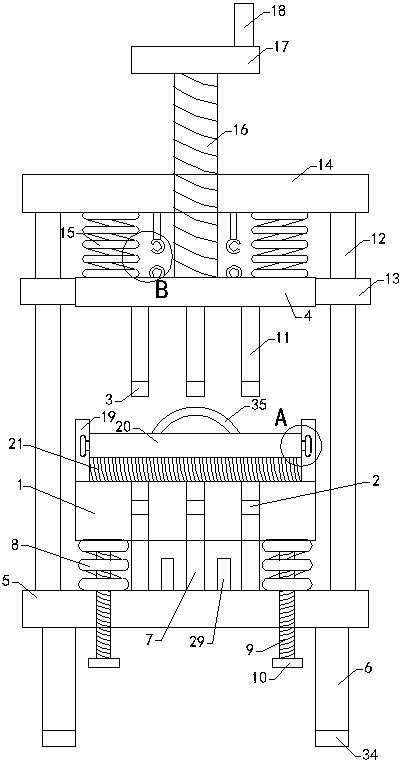

[0021] like Figure 1 to Figure 5As shown, a tablet pressing device for medical drug production of the present invention includes a workbench 1, a group of lower molds 2, a group of upper molds 3 and a lower platen 4; also includes a base 5, a group of support columns 6, A set of lower support rods 7, a set of support springs 8 and a set of adjustable threaded rods 9, the tops of a set of support columns are respectively connected to the left front side, left rear side, right front side and right rear side of the bottom of the base, and a set of Pressing holes, a set of lower molds are respectively installed on the top of a set of lower support rods, the bottom of a set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com