Geological structure physical simulation experiment device for ultra-high gravity field of large-scale centrifugal machine

A technology of supergravity field and geological structure, applied in the direction of educational appliances, teaching models, instruments, etc., can solve the problems of small space in the drum centrifuge cabin, small model modeling size, and large changes in radial acceleration of gravity, etc., to achieve The effect of accurate physical simulation of geological structure, effective space saving and elimination of simulation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

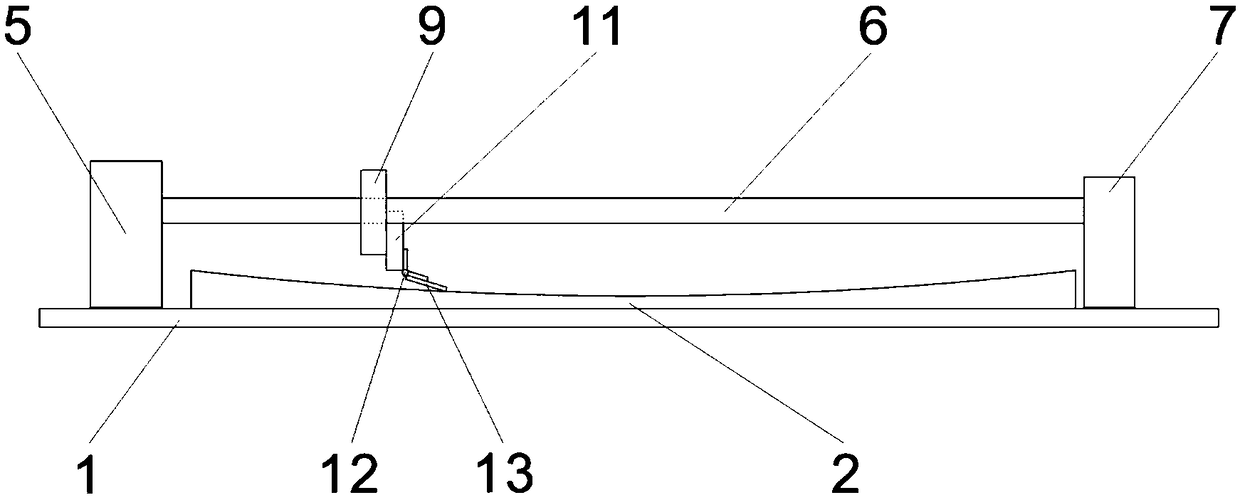

[0028] Such as figure 1 As shown, the present invention includes a bottom plate 1, a curved table 2, a power part and a baffle part.

[0029] Such as figure 1 As shown, the bottom plate 1 is placed on the hanging basket of the centrifuge, and screw assemblies are installed on both sides of the bottom plate 1. The screw assembly includes a screw 6, a sliding guide rail 8, a steering gear 5 and a screw support column 7, and the screw 6 is arranged parallel to the base plate 1, and the two ends of the screw rod 6 are respectively supported and connected between the diverter 5 and the screw rod support column 7, and the diverter 5 and the screw rod support column 7 are fixed on the base plate 1, and the base plate below the screw rod 6 1 are fixed with sliding guide rails 8; the bottom plate 1 between the same ends of the two screw rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com