Pressure balance device and suction cup using the same

A technology of balancing device and pressure, applied in suction cups, connecting components, mechanical equipment, etc., can solve problems such as inability to achieve curved surface adsorption, lack of airtight devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

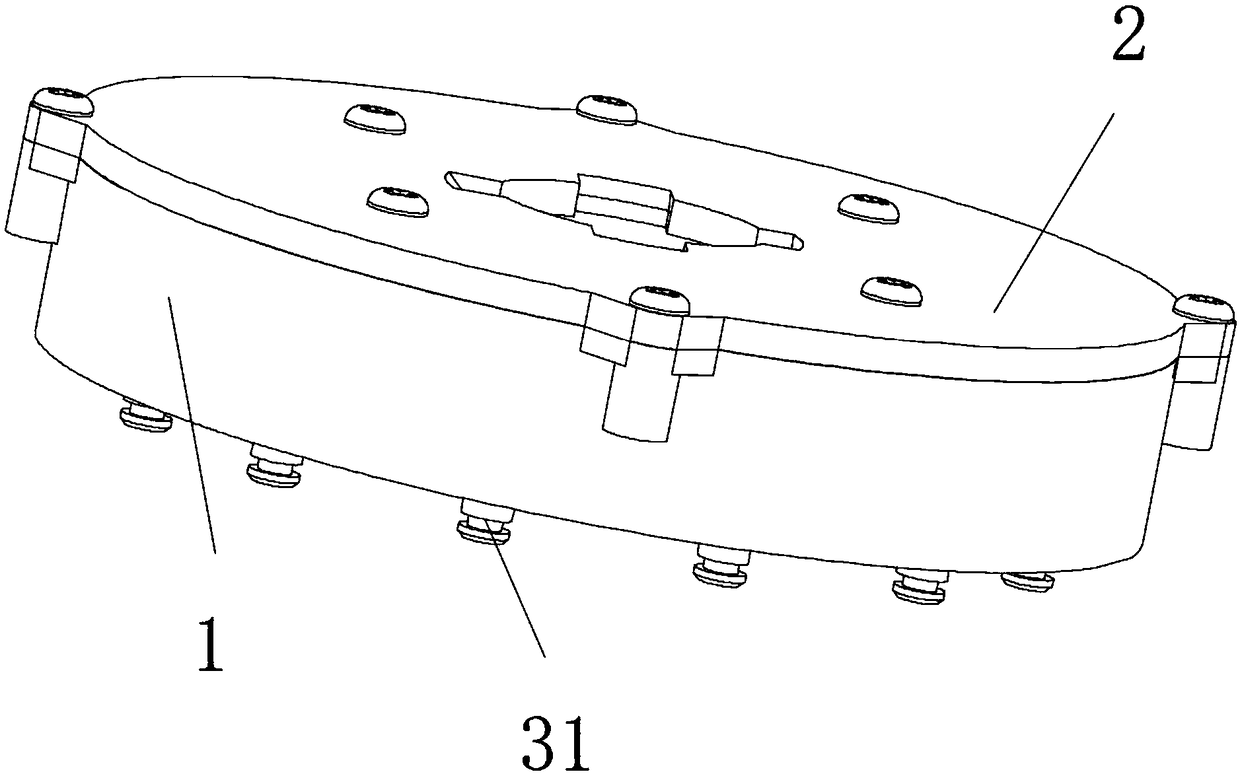

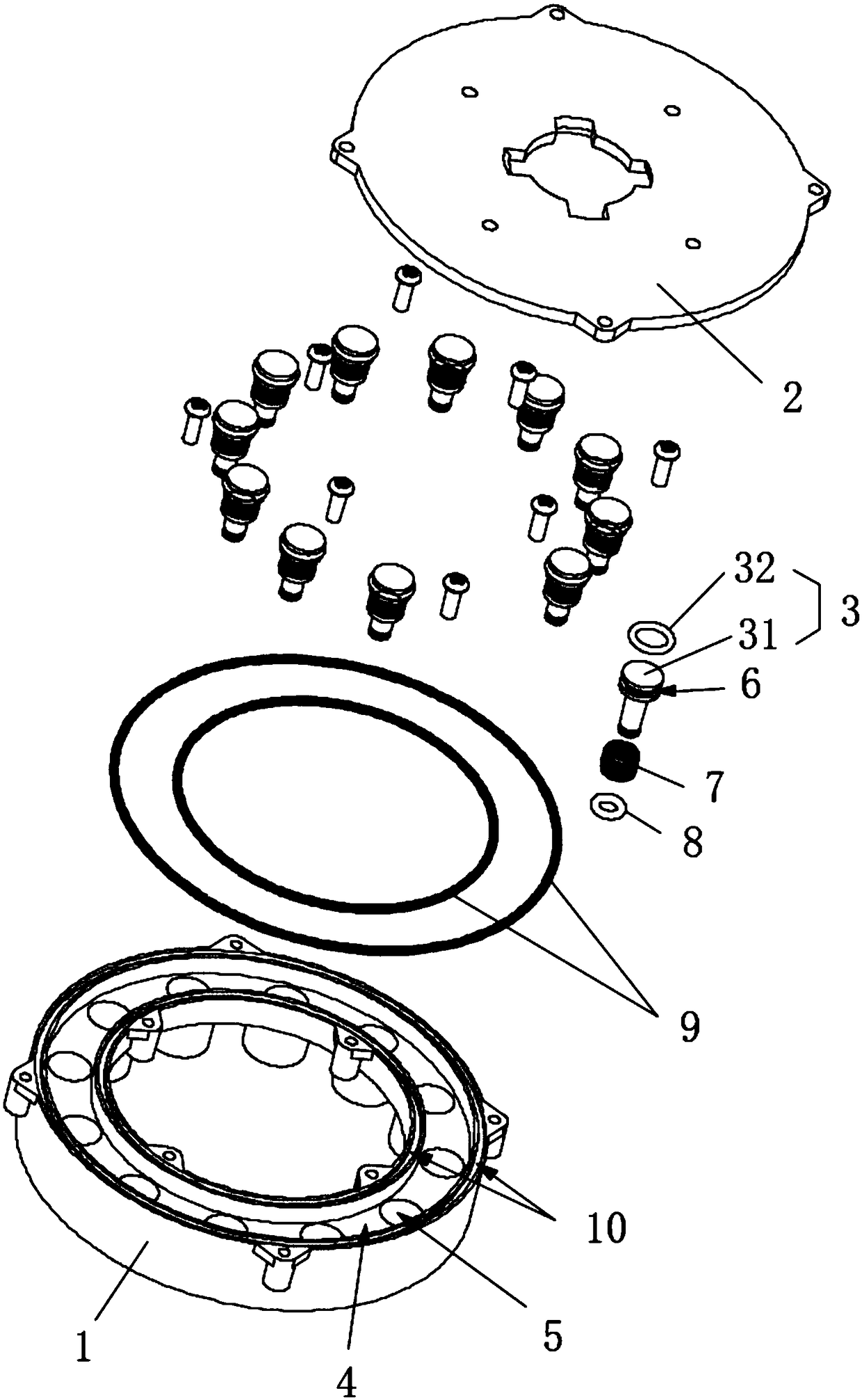

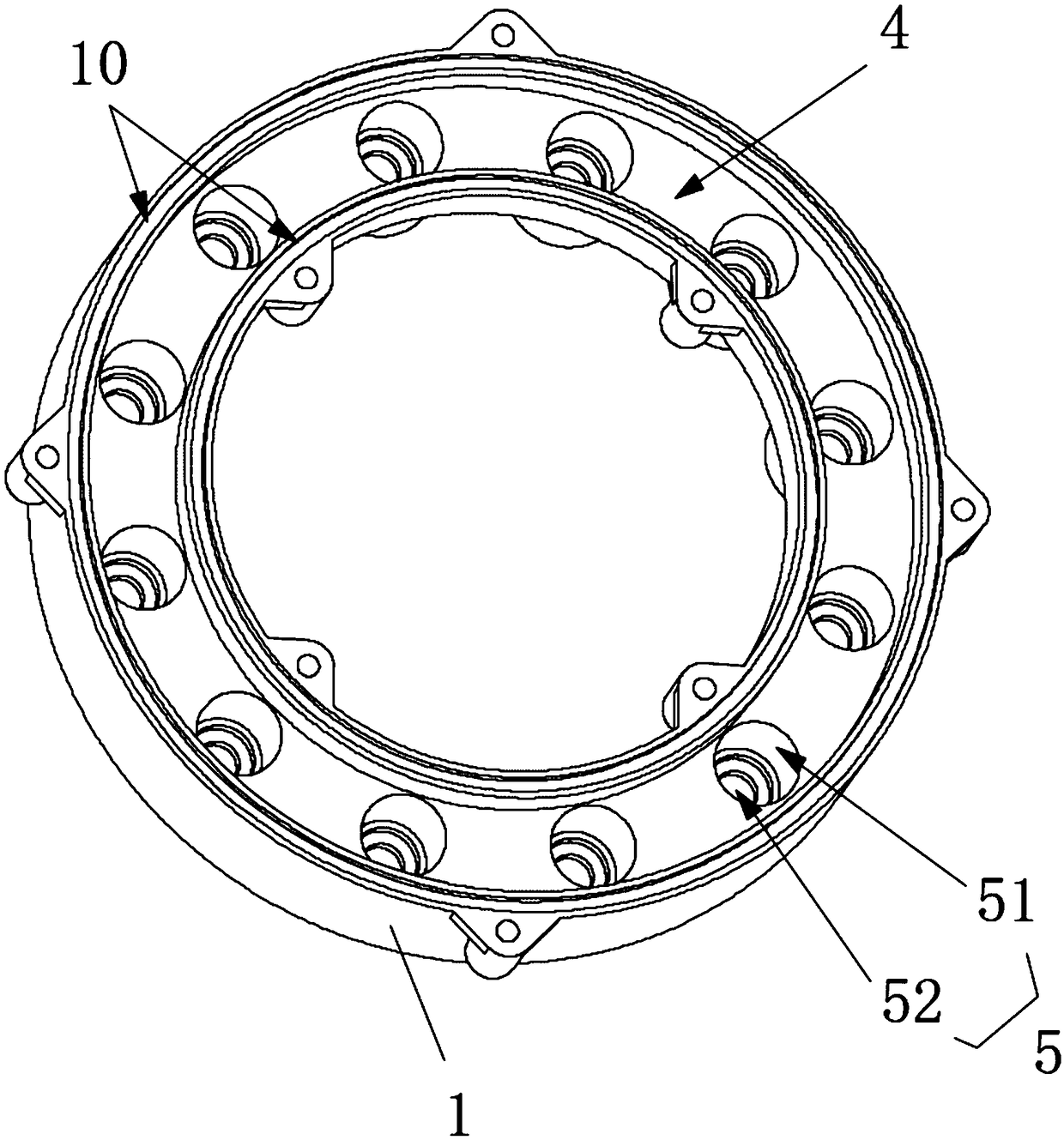

[0024] Such as Figure 1-4 As shown, a pressure balance device includes a base 1, a deformation medium accommodated in the base 1 and capable of being squeezed and deformed, a sealing cover 2 covering the base 1, and a plurality of The connected seal 3, the base 1 is provided with a storage tank 4 for accommodating the deformation medium, the bottom wall of the storage tank 4 is provided with an accommodating through hole 5, and the seal 3 protrudes out of the accommodating through hole 5. The bottom of the hole 5 abuts against the side wall of the accommodating through hole 5, and an airtight cavity is formed between the inner wall of the storage tank 4, the sealing member 3 and the sealing cover 2; when the deformation medium is squeezed by a part of the sealing member , the deformation medium is deformed to squeeze another part of the seal to protrude outward.

[0025] The combination of the base 1, the sealing cover 2 and the sealing member 3 makes the storage tank 4 form...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is:

[0048] The sealing member 3 is a sealing column 31 , and the sealing column 31 is a soft rubber sealing column. The soft rubber sealing column 31 penetrates the bottom of the receiving through hole 5 and abuts against the side wall of the receiving through hole 5 . The soft rubber sealing column is adopted, which has strong expansion ability and is more tightly abutted against the receiving through hole 5, avoiding troubles caused by adding and assembling sealing rings, and saving raw material costs and labor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com