A jit-vmi-based material distribution method for direct supply from suppliers

A JIT-VMI and supplier technology, applied in logistics, data processing applications, forecasting, etc., can solve problems such as low degree of punctuality and reduced customer production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

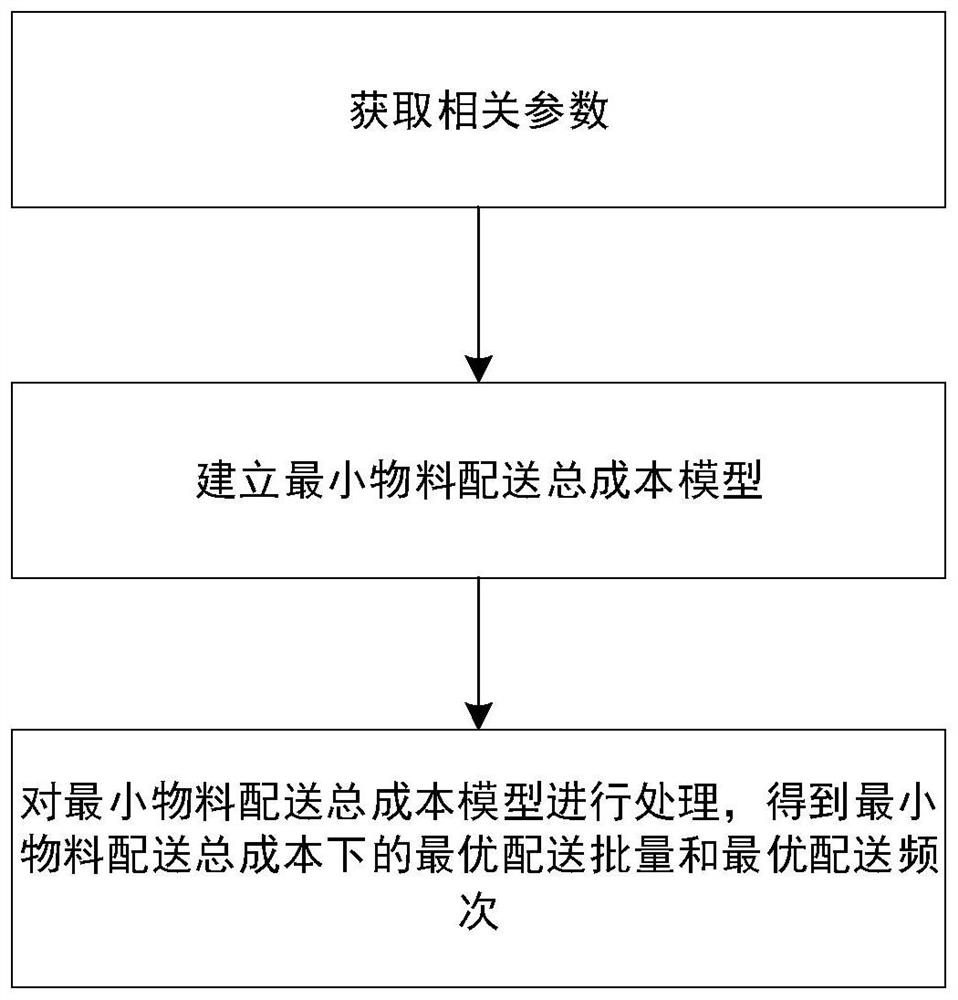

[0037] A JIT-VMI-based supplier direct supply line-side material distribution method, such as figure 1 shown, including the following steps:

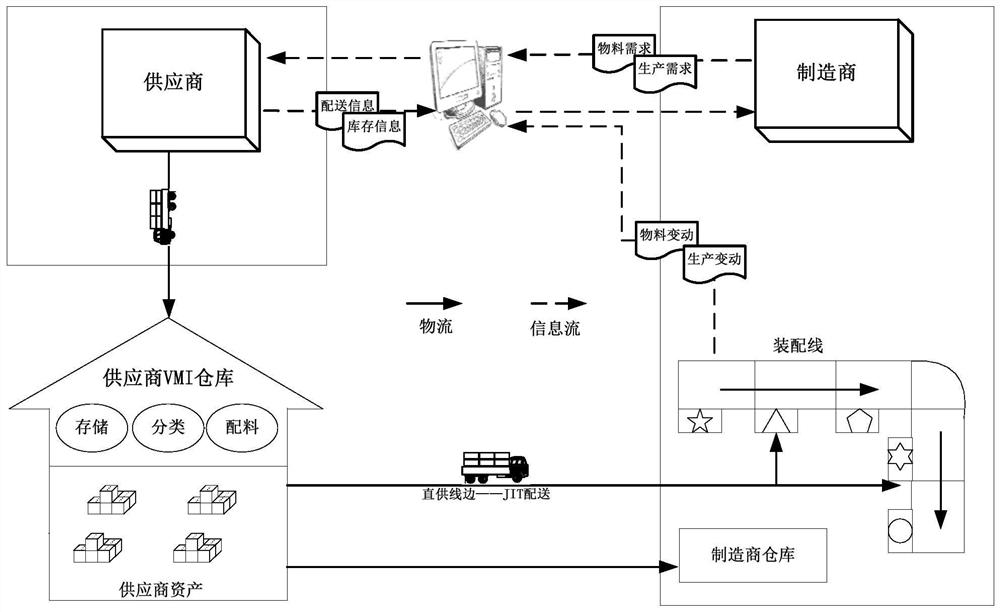

[0038] (1) Obtain the production tact of the supplier's material, the production tact of the manufacturer's assembly line, the cycle time of the production plan, the time for the supplier to deliver the material to the VMI warehouse, the loading and unloading time of the material on the line, the safety stock coefficient of the material in the VMI warehouse, and the cycle time of a production plan Inside, the production volume of the corresponding product, the quantity of materials required to produce a single product, the supply ratio of the supplier to supply the corresponding materials, the VMI material storage cost per unit quantity and unit time, the fixed cost coefficient of one-time material delivery by VMI warehouse, and the unit distance cost coefficient of VMI warehouse delivery , the distance between the VMI warehouse and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com