Method for detecting amylase in oyster oil

A detection method, the technology of amylase, is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problems of enzymatic degeneration of final products and enterprise losses, etc. The effect of food quality, high reliability, and reliable detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

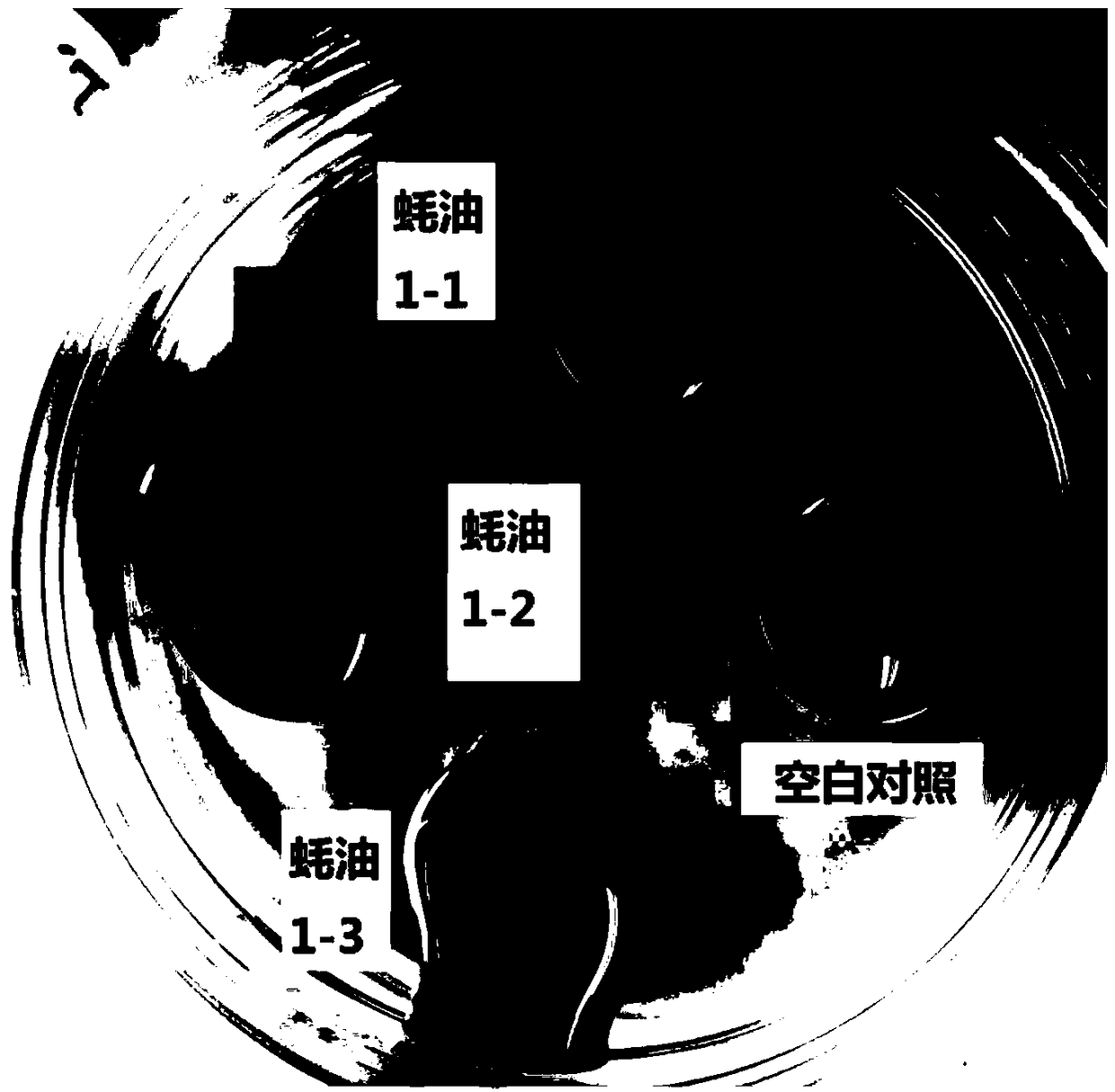

[0027] The detection method of amylase in the oyster sauce provided by the present embodiment specifically comprises the following steps:

[0028] 1. Preparation of reagents

[0029] (1), the preparation of buffer mother solution

[0030] Mother liquor A: Weigh 4.50g NaCl, 4.20g KCl, 1.00g NaHCO respectively 3 and 1.208 g anhydrous CaCl 2 , dissolved in distilled water, adjusted to 200mL, packed in a 500mL Erlenmeyer flask, and sterilized at 120°C for 40min.

[0031] Mother liquor B: weigh 1.5g K 2 Cr 2 o 7 Dissolve in distilled water and dilute to 100mL, pack in a 250mL Erlenmeyer flask, and sterilize at 120°C for 40min.

[0032] (2), preparation of iodine solution

[0033] Weigh 6.50g KI and dissolve in 40mL distilled water, add 1.28gI 2 , dilute to 100mL, and put into a brown bottle.

[0034] (3) Preparation of sterilized water

[0035] Measure 239mL of distilled water into a 500mL Erlenmeyer flask, and sterilize at 120°C for 40min.

[0036] (4), preparation of 3...

Embodiment 2

[0050] 1, the preparation of reagent is the same as embodiment 1.

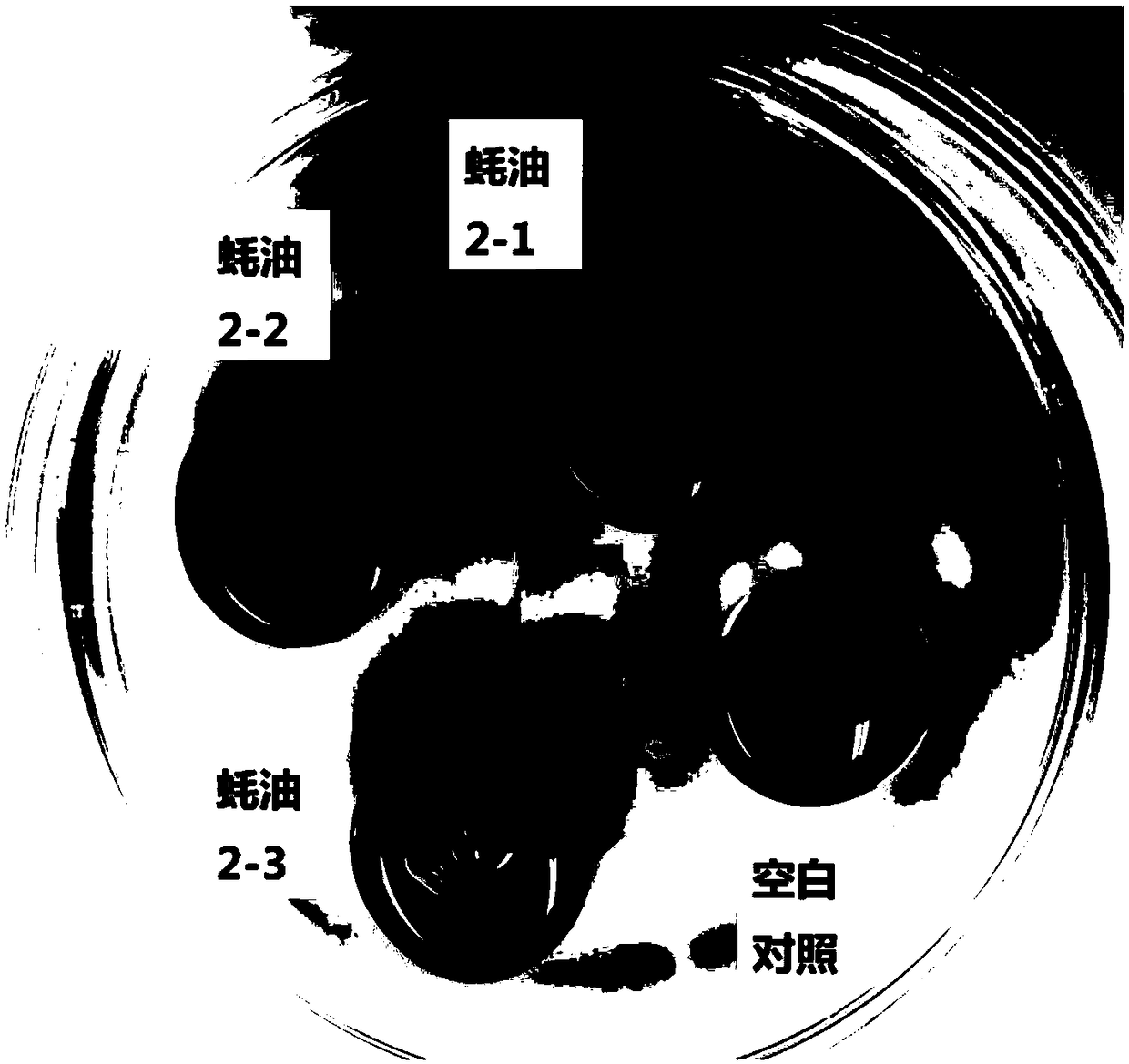

[0051] 2. Detection of amylase in oyster sauce

[0052] Steps (1)-(2), (4) are the same as in Example 1, and the oyster sauce to be tested in step (3) is another batch of oyster sauce.

[0053] When judging the results in step (5), after incubation at constant temperature, pipette 1mL of the blank control and 1mL of the sample to be tested into a white porcelain dish, add a drop of iodine solution and shake well; the blank control becomes brown after adding iodine solution, and the sample to be tested If it is black, it proves that there is no amylase in the oyster sauce, such as figure 2 shown in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com