Series-parallel hybrid power system based on two gearboxes

A hybrid power system and gearbox technology, which is applied to the arrangement of multiple different prime movers of power units, pneumatic power units, and general power units, can solve the problem of high motor requirements, rising motor costs, and inconvenient electrical structure assembly. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

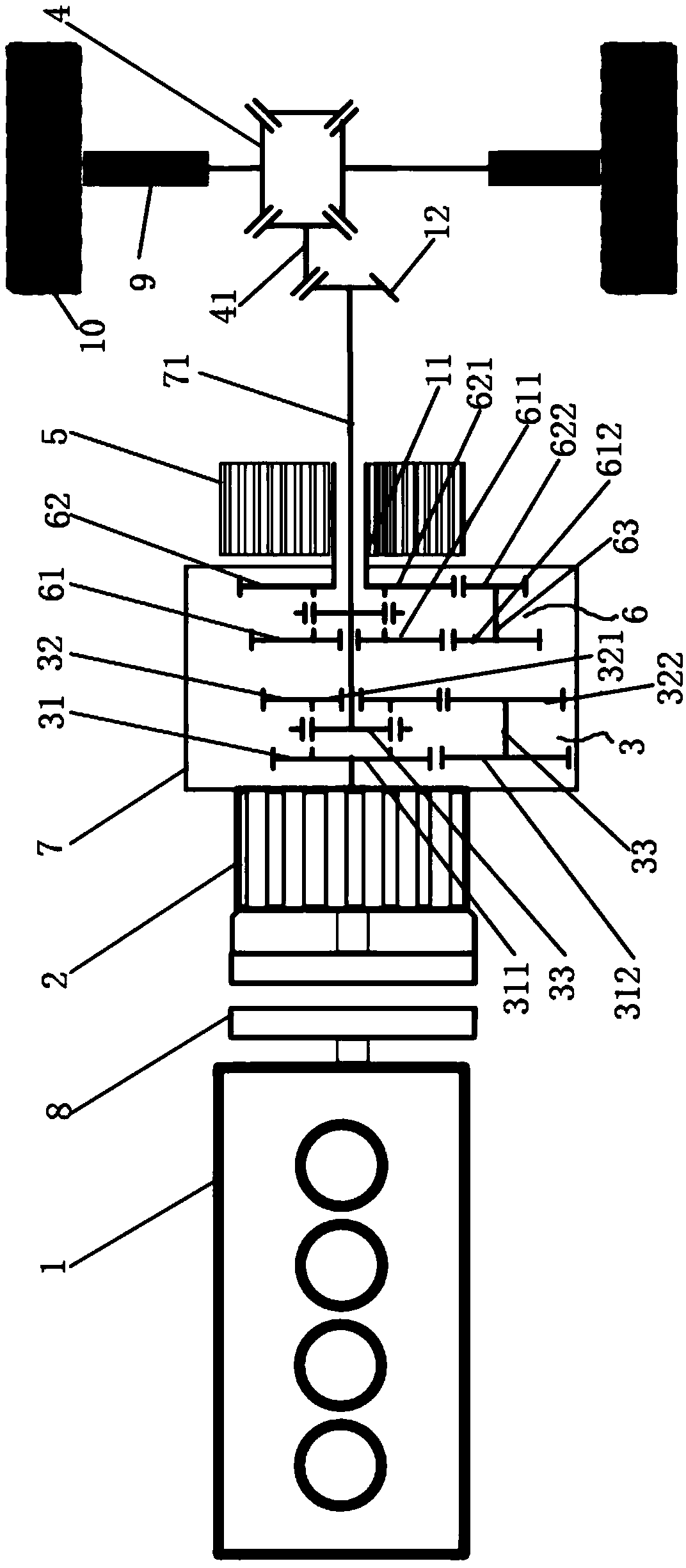

[0018] A hybrid system based on two gearboxes, see figure 1 : It includes an engine 1, a first motor 2, a first gearbox 3, a differential 4, a second motor 5, a second gearbox 6, and the first gearbox 3 and the second gearbox 6 are integrated into one compound box 7 , the output shaft of the first gearbox 3 and the output shaft of the second gearbox 6 are integrated to form an integrated composite box output shaft 71, and the integrated composite box output shaft 71 is connected to the main reduction gear of the differential 4 through the drive shaft, and the second gearbox 6 also includes a protruding input shaft, the protruding input shaft is protruding from one side of the integrated composite box 7 and then connected to the power output part of the second motor 5, the input shaft of the first gearbox 3 is protruding from the other side of the integrated composite box One side is connected to the output end of the motor shaft of the first motor 2, the output shaft of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com