Test tube centrifuge machine for automatic analyzer

A test-tube centrifuge and automatic analyzer technology, which is applied to centrifuges and other directions, can solve the problems of affecting the separation effect, unfavorable vertical pipette suction of liquid, etc., and achieve the effects of convenient use, simple structure and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

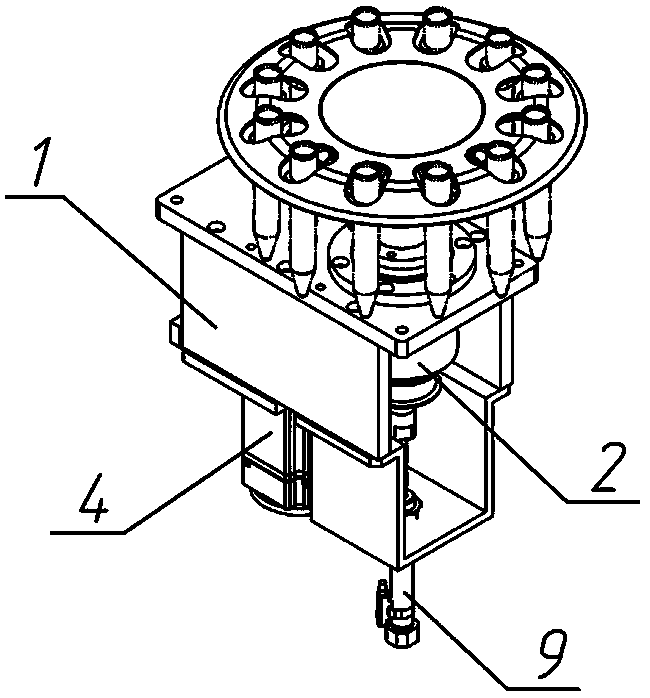

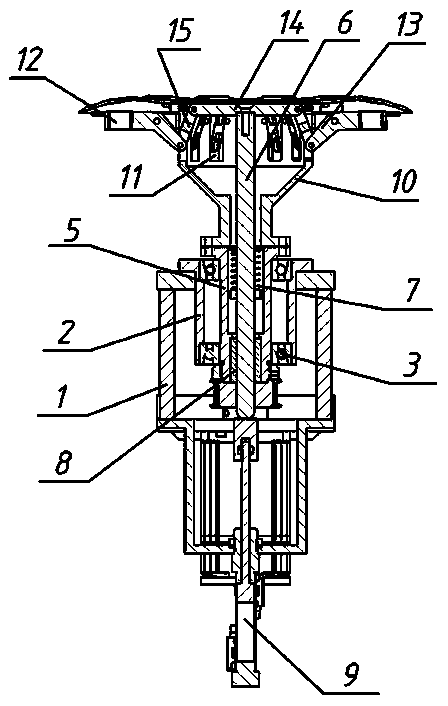

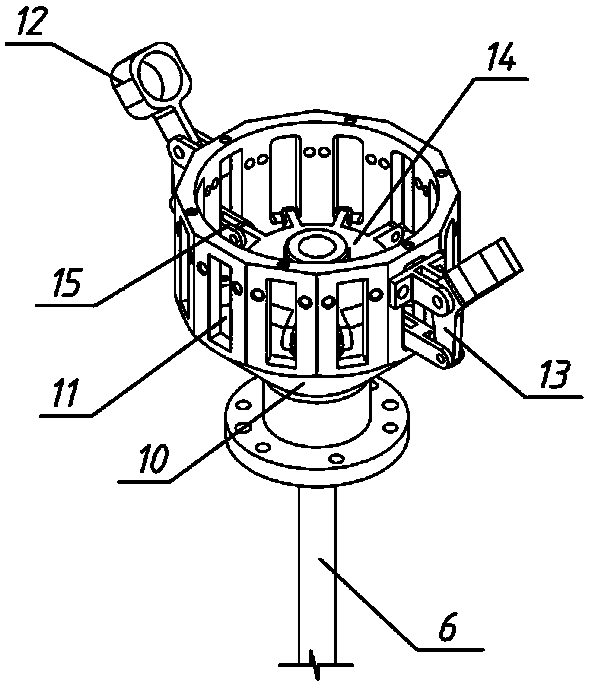

[0015] The test tube centrifuge used for the automatic analyzer of the present invention comprises a rotating shaft and a test tube placing card, and the rotating shaft and the test tube placing card are connected through an angle adjustment mechanism. Illustrate below by specific embodiment:

[0016] Such as Figure 1-3 As shown, the angle adjustment mechanism of the present invention includes an outer sleeve 2 fixedly installed on the top plate of the support frame 1, and an inner sleeve 5 is connected with two upper and lower bearings 3 in the outer sleeve 2, and the inner sleeve 5 passes through The synchronous belt transmission mechanism is connected with the motor 4; the inner sleeve 5 is pierced with a rotating shaft 6, and the rotating shaft 6 is pierced with a compression spring 7, and the two ends of the compression spring 7 are respectively provided with upper limits on the inner sleeve 5 block and the lower limit block located on the rotating shaft 6, the joint su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com