SCR (Selective Catalytic Reduction) honeycomb type denitration catalyst and preparation method thereof

A technology of denitrification catalyst and honeycomb type, which is applied in the field of SCR honeycomb type denitrification catalyst and its preparation, and can solve the performance problems of difficult denitrification catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The specific steps of the preparation method are as follows:

[0049] Add titanium dioxide, carboxymethyl cellulose, and polyethylene oxide into the mixer and mix thoroughly, add fibers, and stir for 5 minutes at a speed of 200 r / min. Add deionized water, ammonium metavanadate, ammonium metatungstate, ammonia water, lactic acid, cerium nitrate hexahydrate, and praseodymium nitrate hexahydrate, and stir for 25 minutes; turn on the dehumidifier and dehumidify for 35 minutes, and the moisture content of the final material is 25-30%.

[0050]The material is extruded through the filter plate with SCR porous catalyst wet embryo to filter, and the material whose particle size is smaller than the mesh of the filter plate is left, and the filtered material is subjected to mud treatment; the processed material is put into the extruder and extruded into shape; The formed materials are stacked on the primary drying kiln car with wet-end automation equipment, and the primary drying...

Embodiment 1

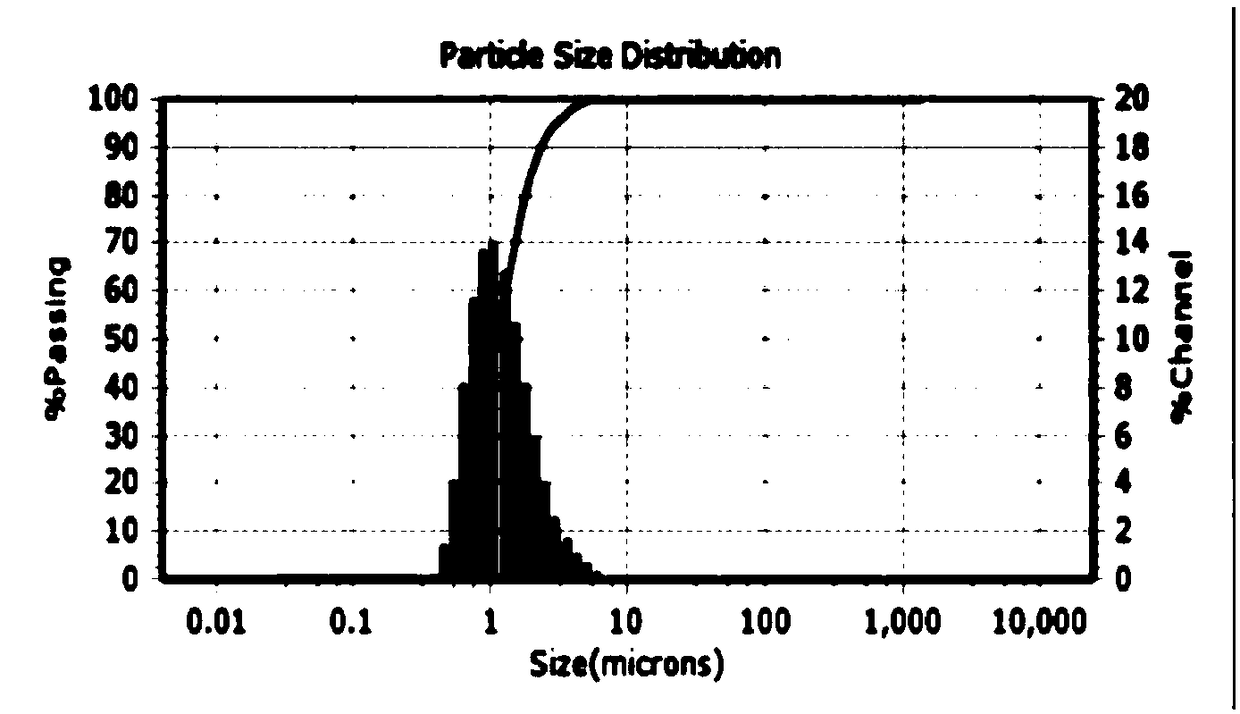

[0052] In this embodiment, 1000 kg of titanium dioxide is used, and the fiber selected to be added is 80 kg of Rp-chop and glass fiber, wherein the particle size of titanium dioxide is d 10 = 0.56 μm, d 50 = 1.27 μm, d 90 =3.64 μm, fiber diameter R=7 μm, distribution of fiber length L is 8 kg for 3 mm fibers, 64 kg for 7 mm fibers, and 8 kg for 20 mm fibers.

[0053] Among them, R=5.51d 50 ;L=5357d 10 、5511d 50 、5494d 90 , the weight ratio of three different length fibers is 1:8:1, and the weight ratio of fiber to titanium dioxide is 0.08:1.

Embodiment 2

[0055] In the present embodiment, the fiber selected to add is 90kg of wood pulp and glass fiber, wherein the particle size of titanium dioxide is d 10 = 0.67μm, d 50 = 1.12 μm, d 90 = 2.37 μm, fiber diameter R = 7 μm, and distribution of fiber length L: 22.5 kg of 3.5 mm fibers, 45 kg of 6.5 mm fibers, and 22.5 kg of 12 mm fibers.

[0056] Among them, R=6.25d 50 , L=5223d 10 、5803d 50 、5063d 90 , the adding weight ratio of three different length fibers is 1:2:1, the adding mass ratio of fiber and titanium dioxide is: 0.09:1, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com